Method for preparing nano ceramic insole capable of generating anions

A technology of nano-ceramic and nano-ceramic particles, which is applied to insoles, footwear, clothing, etc., can solve the problems of single production method and poor air permeability, and achieve the effect of simple and practical production method and remarkable technical effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

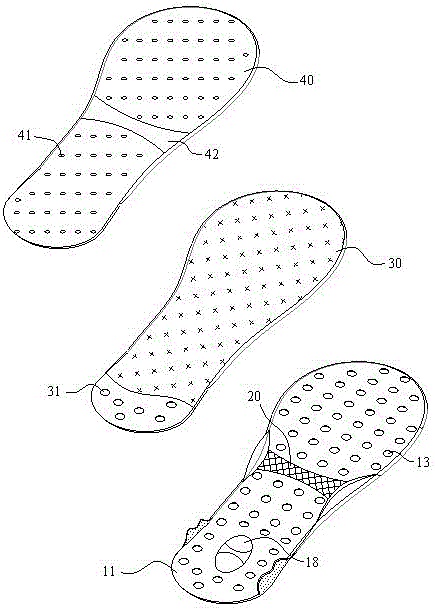

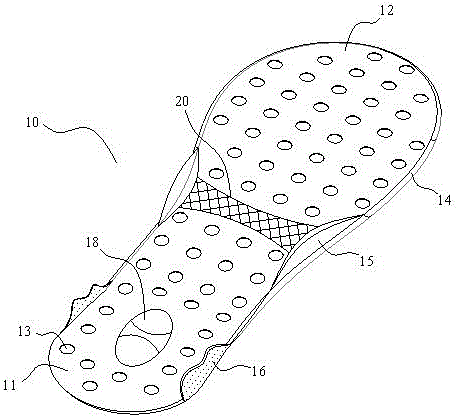

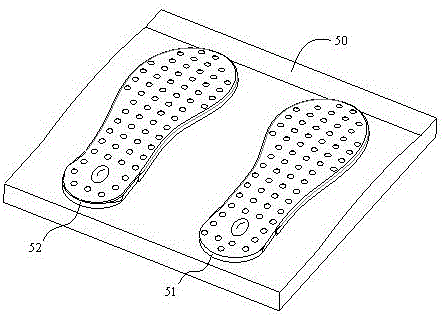

[0020] Such as figure 1 As shown, the present invention provides a kind of preparation method of the nano-ceramic insole that can produce negative ions, comprises the following steps: step 1, preparation of upper pad 40; Step 2, preparation of negative ion fiber felt layer 30; Step 3, preparation of lower pad 10; Step four, composite pressing. In step 2, the non-woven fabric fiber is first made into a felt, then the nano-ceramic particles are mixed with the negative ion slurry and immersed in the non-woven fiber felt, and the negative-ion fiber felt layer 30 is obtained after drying. The nano-ceramic particles include nano-oxidized One or more of titanium, nano-zirconia or nano-silver powder, the negative ion slurry can use the invention patent No. 201110154902.7 "a slurry that can generate negative ions, its preparation method and its use in the preparation of air-purifying filter materials "Application of the anion slurry" (this patent was applied for by the applicant and h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com