Environment-friendly material raw material mixing device convenient to clean

A technology of environmentally friendly materials and mixing equipment, which is applied to mixers with rotating stirring devices, mixers, cleaning hollow objects, etc., can solve problems such as cumbersome operations, safety, cost, unsatisfactory construction period, and difficult to control the quality of the preparation. Achieve the effects of easy inspection and maintenance, complete discharge, and prevention of cross-contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

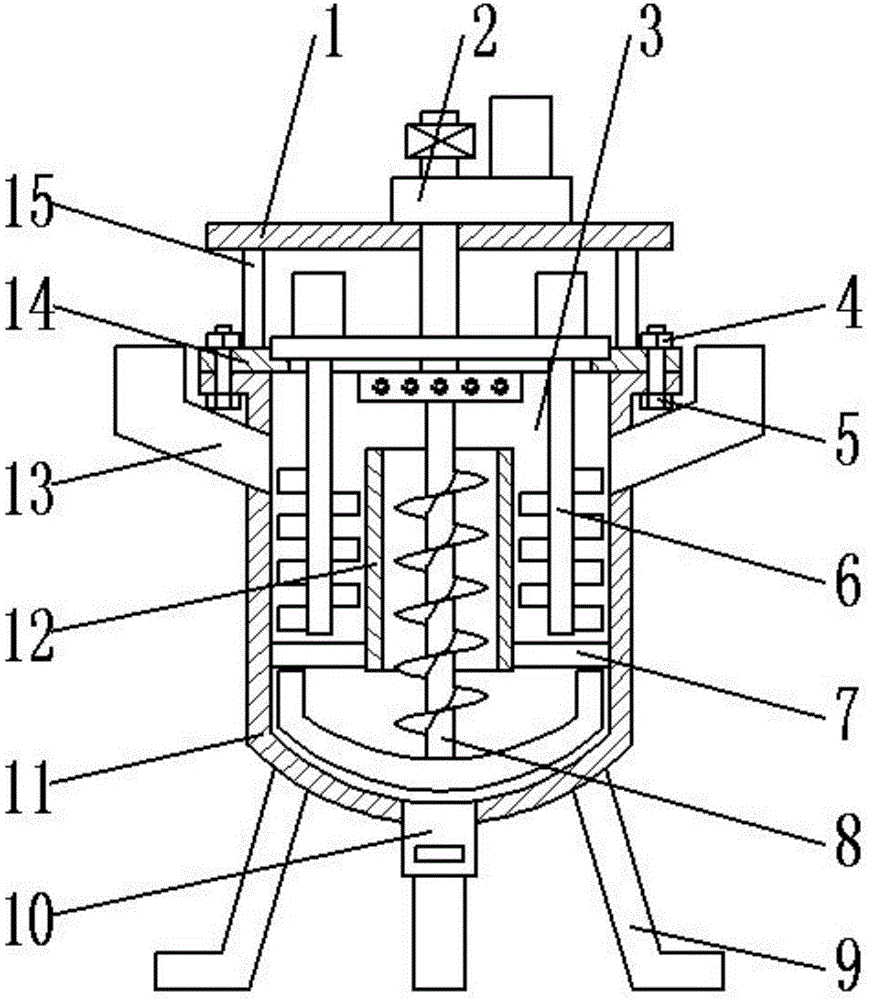

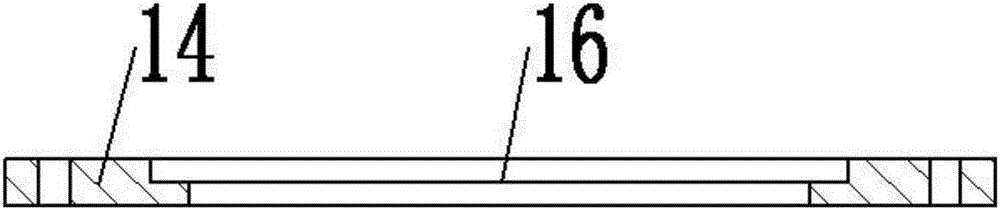

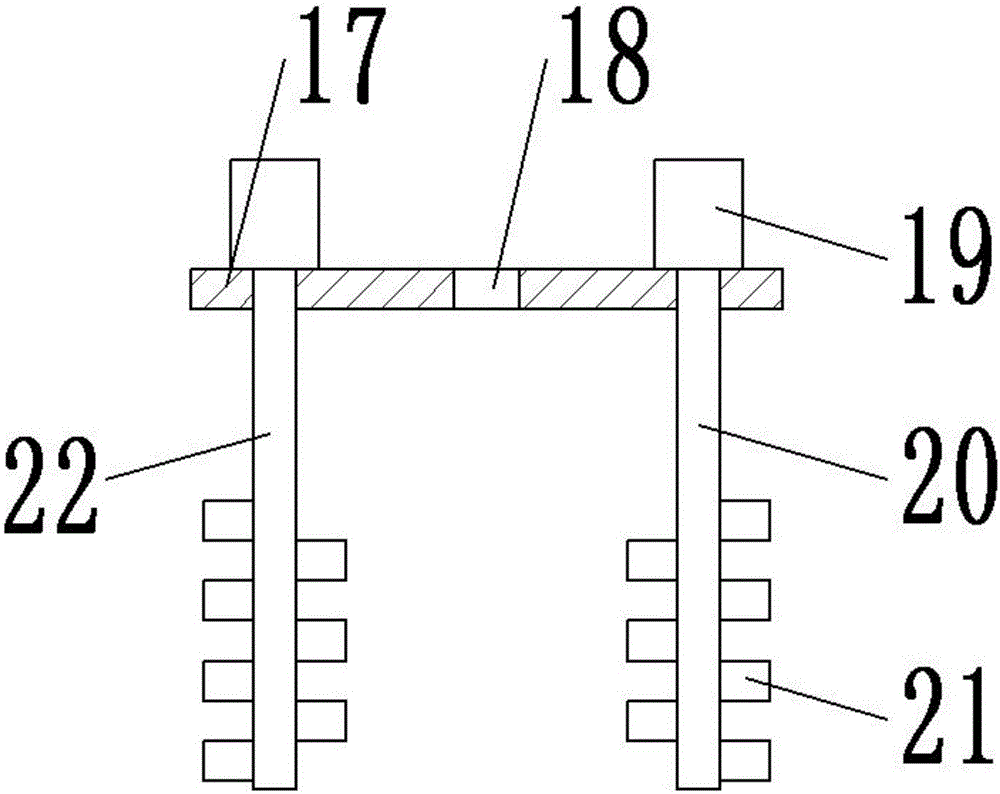

[0018] see Figure 1-5 , a kind of raw material mixing equipment of environmentally friendly materials that are easy to clean, comprising a tank body 11 and a top cover 14; The inside of 11 is set as a mixing chamber 3; the upper cover 14 is fixedly connected with the tank body 11 through the mutual screwing of the bolt 5 and the nut 4; the upper cover 14 is detachably connected with the tank body 11 through the screwing of the bolt 5 and the nut 4 , to facilitate the inspection and maintenance of the equipment; the middle part of the upper cover 14 is provided with an installation groove 16, and the upper surface is connected with the top plate 1 through the support column 15; the cleaning and driving device 2 is arranged on the top plate 1; the cleaning and driving device 2 It is composed of a transmission box 34, a rotating motor 33, a water in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com