Coal-gangue separation system and separation method

A separation system and coal gangue technology, applied in the field of coal mine machinery, can solve the problems of low production efficiency, easy to occur missed selection, high labor intensity, etc., and achieve the effects of improving the recognition rate, reducing the difficulty and simple control method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

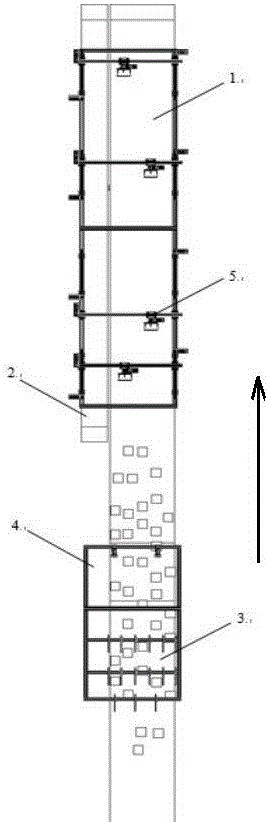

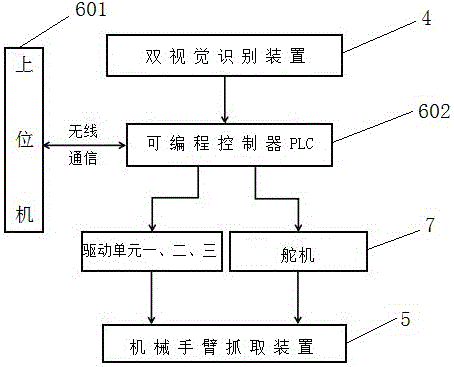

[0039] In order to improve the separation efficiency of coal and gangue, protect the ecological environment of coal mine production, and improve the existing rough gangue selection method, the present invention provides a coal gangue separation system, such as figure 1 As shown, it includes a gangue flow conveyor belt 1, a gangue flow conveyor belt 2, a control device 6, a diversion device 3 installed above the gangue flow conveyor belt 1, a double visual recognition device 4, and a mechanical arm grabbing device installed above the two conveyor belts 5. Gangue flow conveyor belt 1 and gangue flow conveyor belt 2 are arranged side by side;

[0040] The distribution device 3 , dual visual recognition device 4 and mechanical arm grabbing device 5 are distributed sequentially along the conveying direction of the coal gangue conveyor belt 1 , and the dual visual recognition device 4 and the mechanical arm grabbing device 5 are electrically connected to the control device 6 .

[00...

Embodiment 2

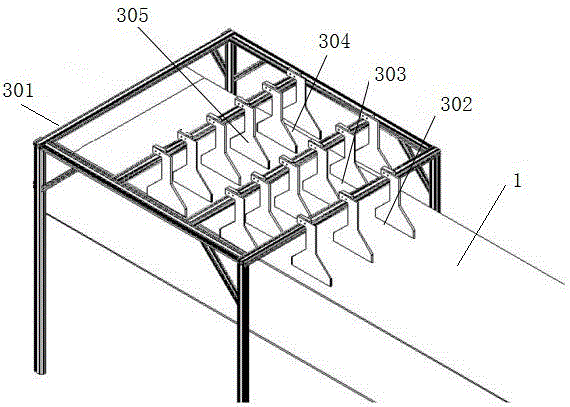

[0045] On the basis of Example 1, such as image 3 As shown, the diversion device 3 includes a diversion support 301 erected across the coal gangue flow conveyor belt 1, along the conveying direction of the coal gangue flow conveyor belt 1, three groups of diversion baffles 305 are installed on the diversion support 301, which are respectively coarse grouping 302, subdividing one group 303 and subdividing two groups 304, the number of subdividing one group 303 and subdividing two groups 304 of diversion baffles 305 is greater than the quantity of coarse grouping 302 diversion baffles 305, and any group of internal phase The distance between the two adjacent diverter baffles 305 is adjustable, and the front and rear ends of the diverter baffles 305 are in contact with the coal gangue as blades.

[0046] Distribution device 3: Arrange multi-component flow baffles 305 on the beam of the distribution bracket 301 (perpendicular to the conveying direction of the conveyor belt), and ...

Embodiment 3

[0048] On the basis of Example 1, such as Figure 4 As shown, the double visual identification device 4 includes an identification bracket 401 erected across the coal gangue flow conveyor belt 1, and two cameras are installed on the identification bracket 401, which are respectively an industrial camera 402 and an infrared camera 403. The lenses are all facing the incoming coal direction of the coal gangue flow conveyor belt 1 .

[0049] The dual vision identification device 4 is based on the infrared imaging identification, and the combination of grayscale identification is added. Both the industrial camera 402 and the infrared camera 403 have camera brackets suspended on the identification bracket 401 .

[0050] Infrared recognition: Infrared camera 403 uses the principle of infrared imaging to distinguish coal gangue and coal on the image according to the difference in temperature. As long as the radiation energy is received, collected and detected, and the signals sent by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com