3D printing forming device integrating sanding and printing

A 3D printing and sand laying technology, which is applied in the directions of casting mold components, casting molding equipment, casting molds, etc., can solve the problems of low production efficiency and long time for a single sand mold, and achieve the goal of improving efficiency, optimizing structural layout, and improving manufacturing speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

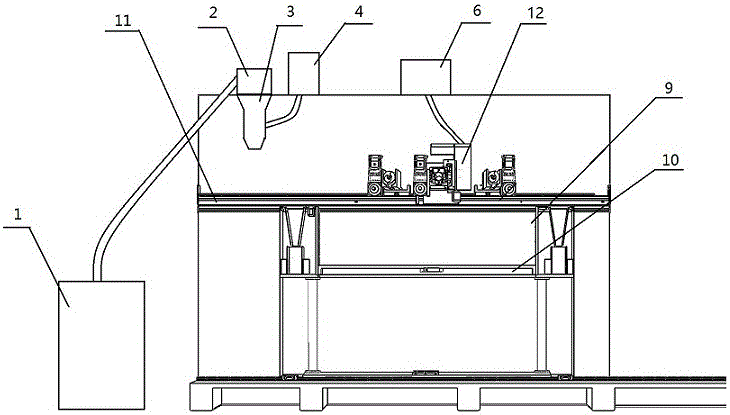

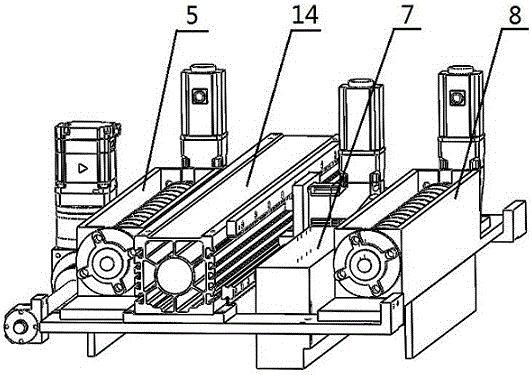

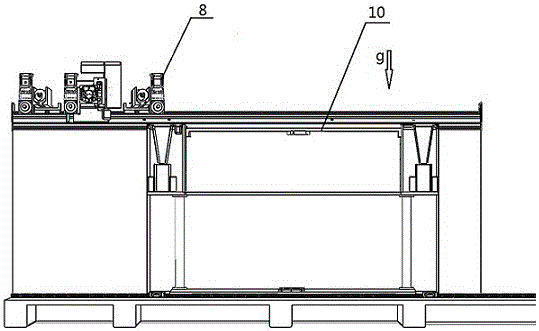

[0024] The present invention proposes an integrated molding device for sand laying and printing, such as figure 1 As shown, the device includes: a sand storage tank 1, storing enough molding sand before printing sand molds, the sand storage tank 1 is connected with a vacuum feeding device 2, and the vacuum feeding device 2 sucks the molding sand into the sand mixing device 3, and the sand mixing device 3 is also connected with the curing agent storage tank 4, and the curing agent storage tank 4 sends the curing agent into the sand mixing device 3 to be stirred together with the molding sand, and the molding sand and the curing agent are uniformly mixed in the process. After the printing starts, the sand mixing device 3 sends the molding sand not mixed with curing agent into the sand paving device (P1) 8 of the double sand paving and printing integrated device. The integrated device 12 will move horizontally from left to right to evenly lay a layer of bottom sand, and then move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com