Servo mechanism oil level potentiometer nut screwing-down device and screwing-down and disassembling method

A technology of servo mechanism and potentiometer, applied in the direction of wrenches, manufacturing tools, wrenches, etc., can solve the problems of high processing cost, extremely strict quality requirements, and impact on delivery of aerospace products, and achieve low cost, simple structure, and assembly reliability. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention has designed a set of device that the oil level potentiometer nut is installed aiming at the above problems. This set of devices can cleverly avoid and protect the resistance of the oil level potentiometer, and at the same time can quickly tighten the two nuts and apply the required torque. At the same time, this set of devices can be expanded and applied to other servo mechanisms with similar structures and assembly requirements.

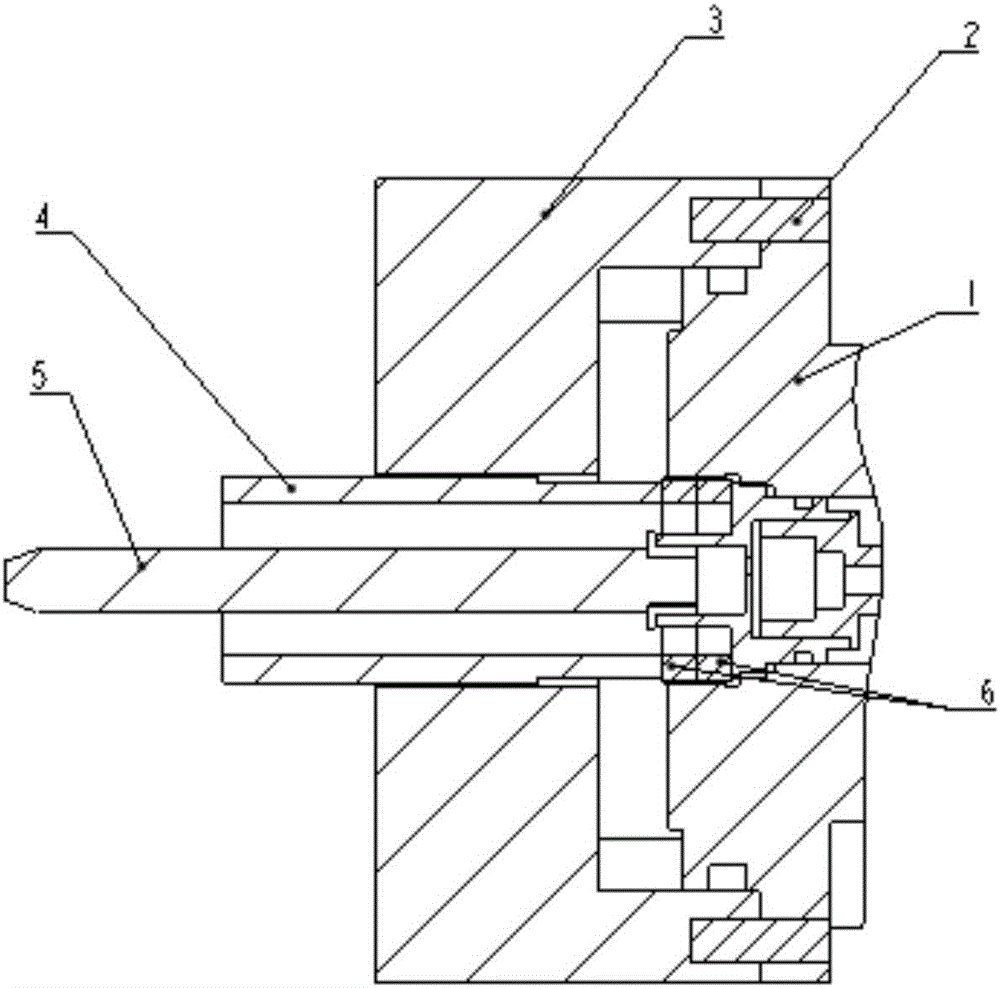

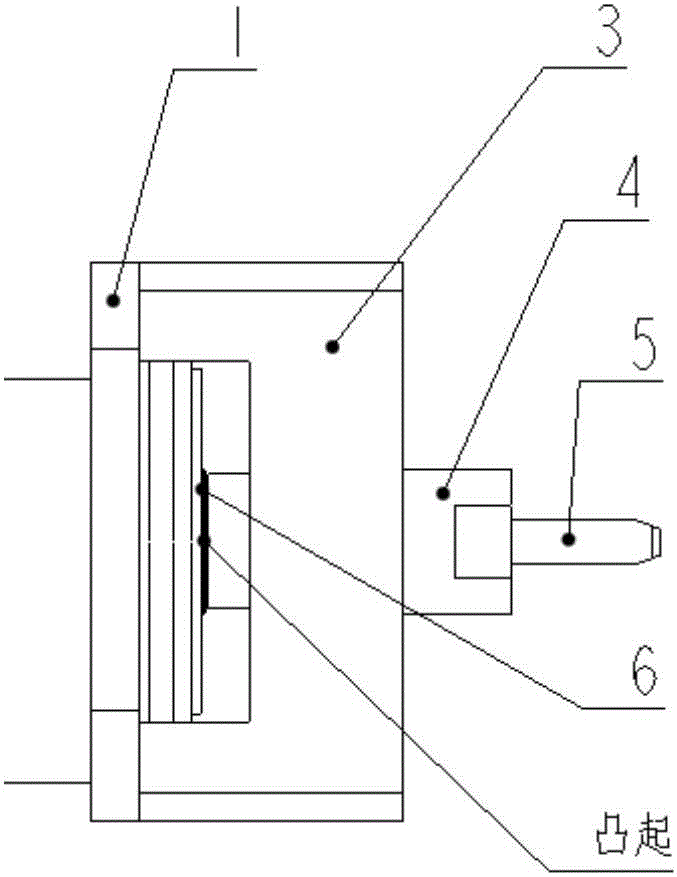

[0036] Such as figure 1 and figure 2 As shown, the present invention provides a device for tightening and dismounting the oil level potentiometer nut of a servo mechanism, which mainly includes a fixing pin 2, a protective cover 3 and a tightening tool 4;

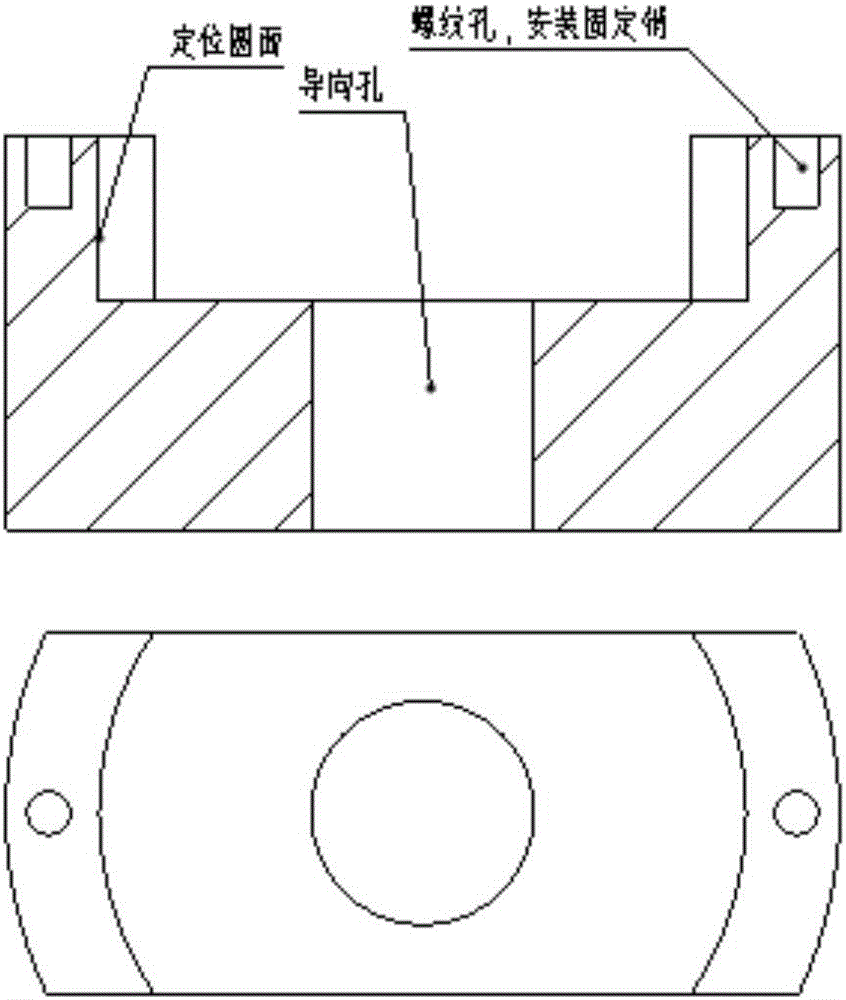

[0037] The protective cover 3 is a structural member with a U-shaped cross section, such as image 3 shown. The protective sleeve 3 is provided with two stepped inner holes in the axial direction, the first smaller inner hole is a guide hole, which cooperates wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com