On-line fiberboard saw powder recovery system

A recycling system, fiberboard technology, applied in the direction of wood processing equipment, bark area/debris/dust/waste removal, manufacturing tools, etc., can solve the problems of manual on-site collection, a large amount of dust, pollution of the surrounding working environment, etc., to eliminate Effects of pollution, labor intensity reduction, and manpower saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

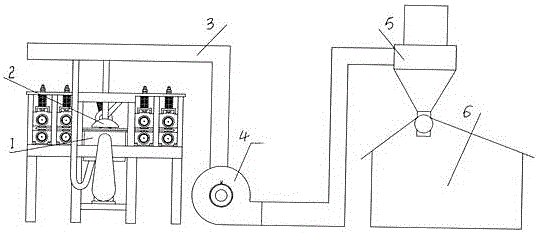

[0009] Embodiments are described in detail in conjunction with the above accompanying drawings, as figure 1 As shown, the edge sawing machine is covered with a dust collection cover, the dust collection cover 1 is fixed on the frame by screws, and the dust cover 2 is installed on the top of the dust collection cover to connect with the air delivery pipeline 3 through the pipeline, and the air delivery pipeline is A fan 4 is installed, and the sawdust is transported to the bag filter 5 by the fan through the air delivery pipeline. Valve links to each other with the inlet on the storage bin 6. The fan is preferably a centrifugal material conveying fan.

[0010] When working, the edge sawing machine trims the edges and corners of the medium density fiberboard conveyed from the upstream neatly, and the flying sawdust is collected by the dust collecting hood and sent to the bag filter through the air delivery pipe. , The rotary valve enters the storage bin, so the problems of sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com