Vertical lift with multi-stage electromagnetic auxiliary braking energy saving safety device and control method

A technology of auxiliary braking and safety devices, applied in transportation, packaging, elevators, etc., to solve the problem of sliding ladders, reduce personal injuries, and enhance the effect of braking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

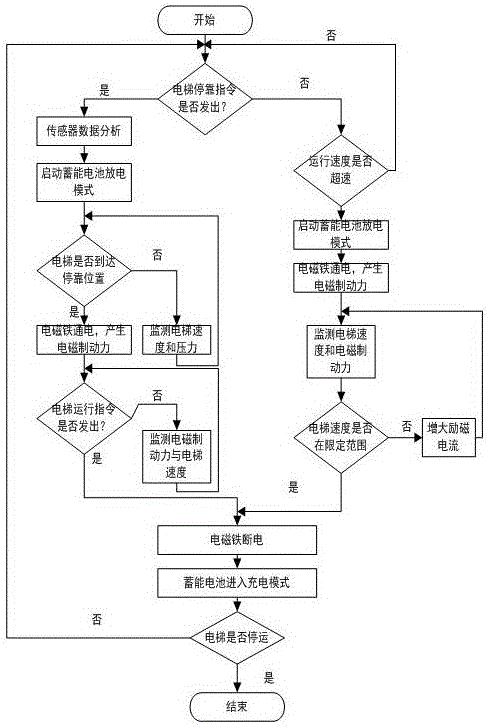

[0021] The invention provides a vertical elevator with a multi-stage electromagnetic auxiliary braking energy-saving safety device and a control method, which can increase the braking force of the vertical elevator, help to solve the problem of the elevator sliding caused by insufficient mechanical braking force, and increase the movement resistance at the same time to help It is used to reduce the running speed of overspeed or stalled elevators, improve the safety and reliability of elevators, and reduce personal injuries to passengers.

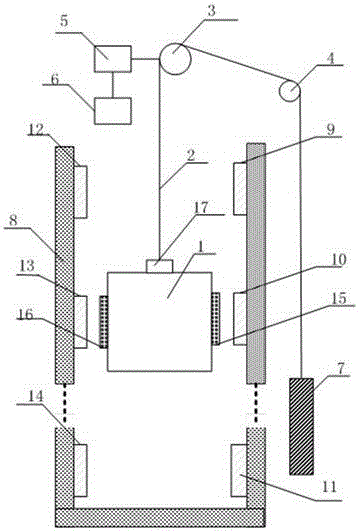

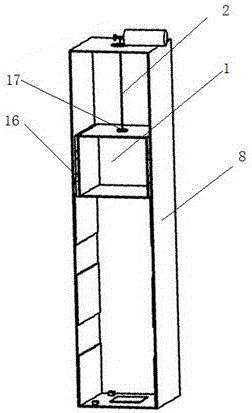

[0022] As an embodiment of the present invention, the present invention provides a vertical elevator with a multi-stage electromagnetic auxiliary braking energy-saving safety device, including a car 1, a rope 2, a traction machine and a pulley assembly 3, a speed limiter 4, and a generator 5 , energy storage b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com