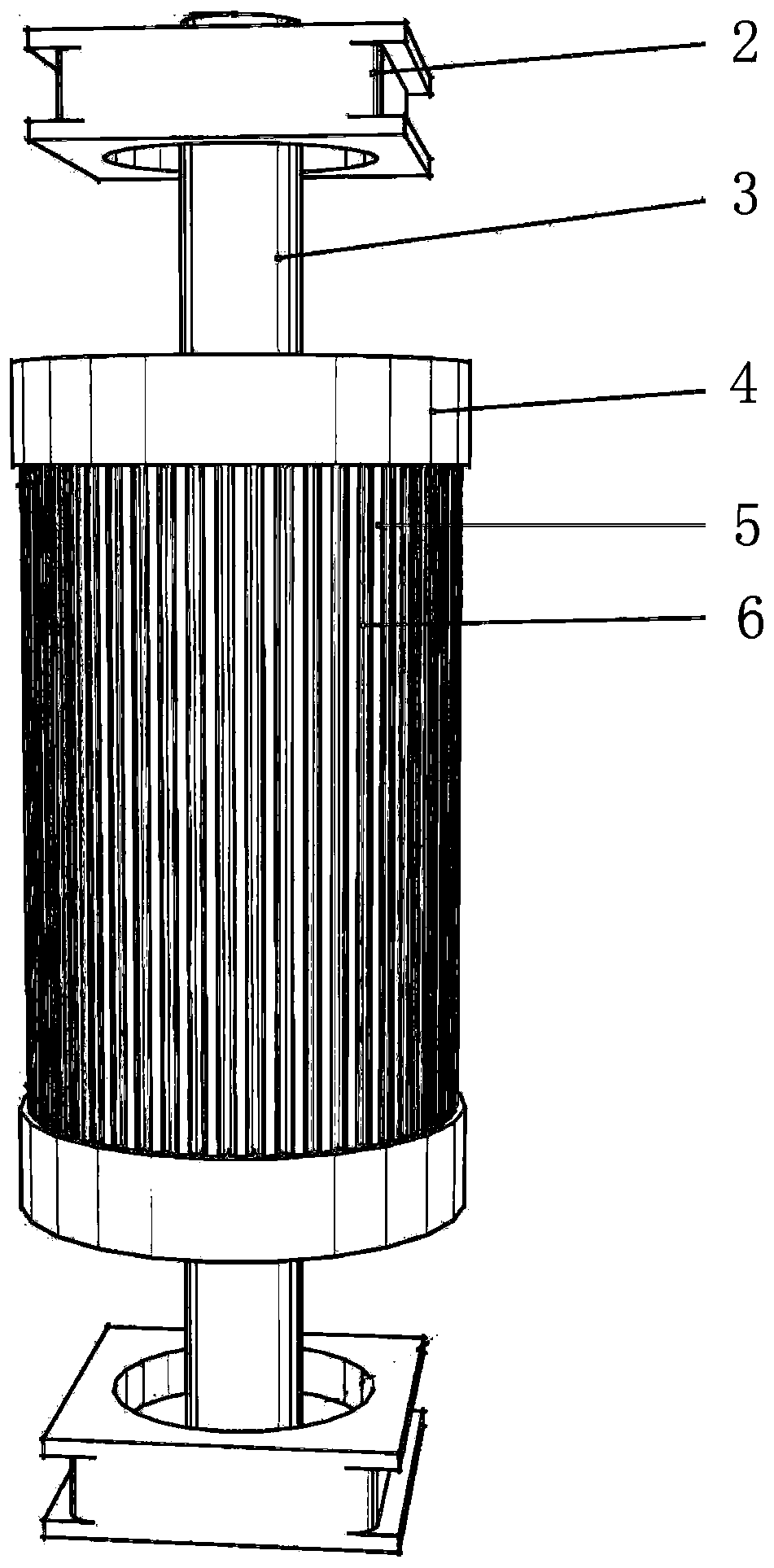

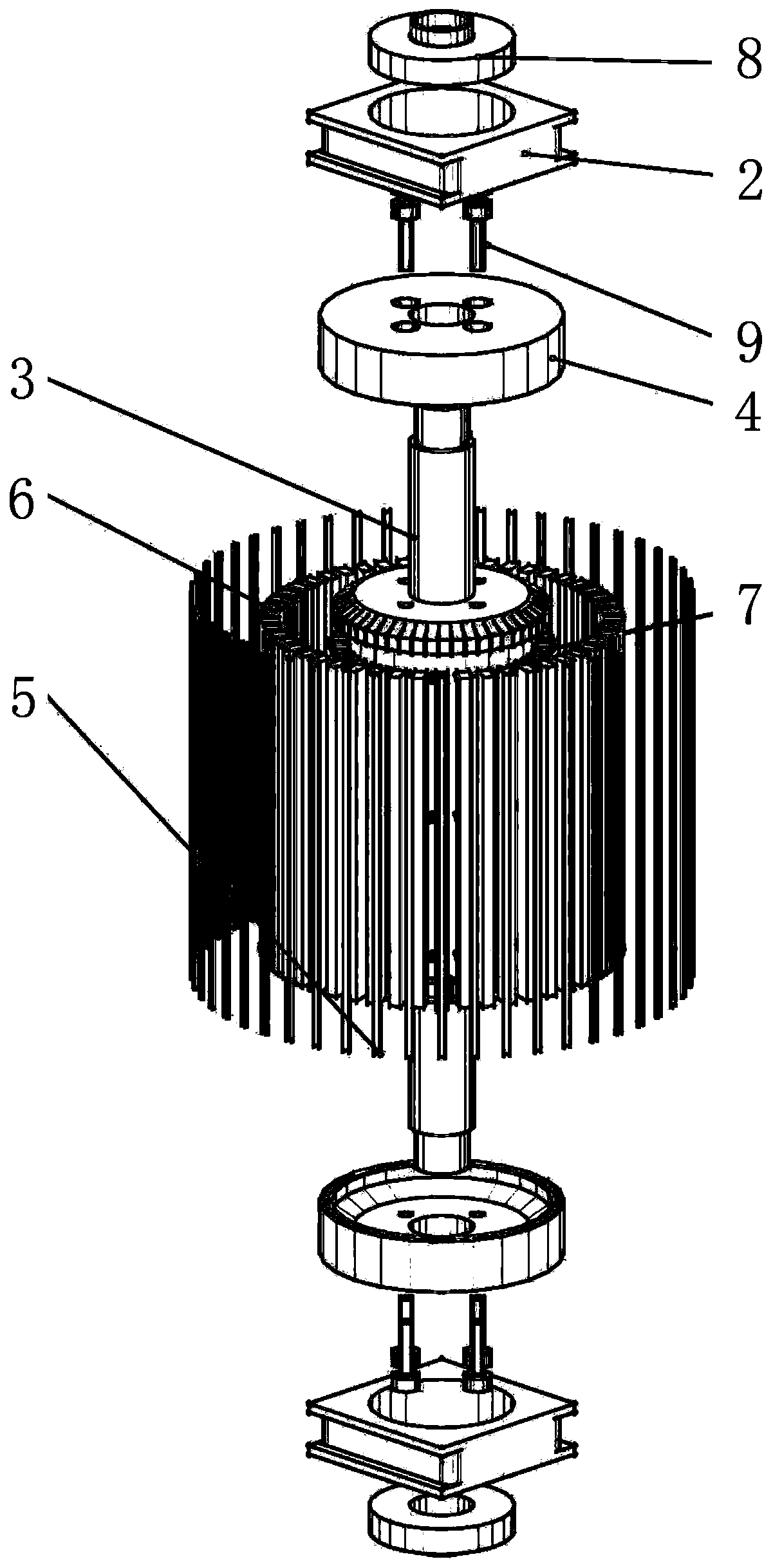

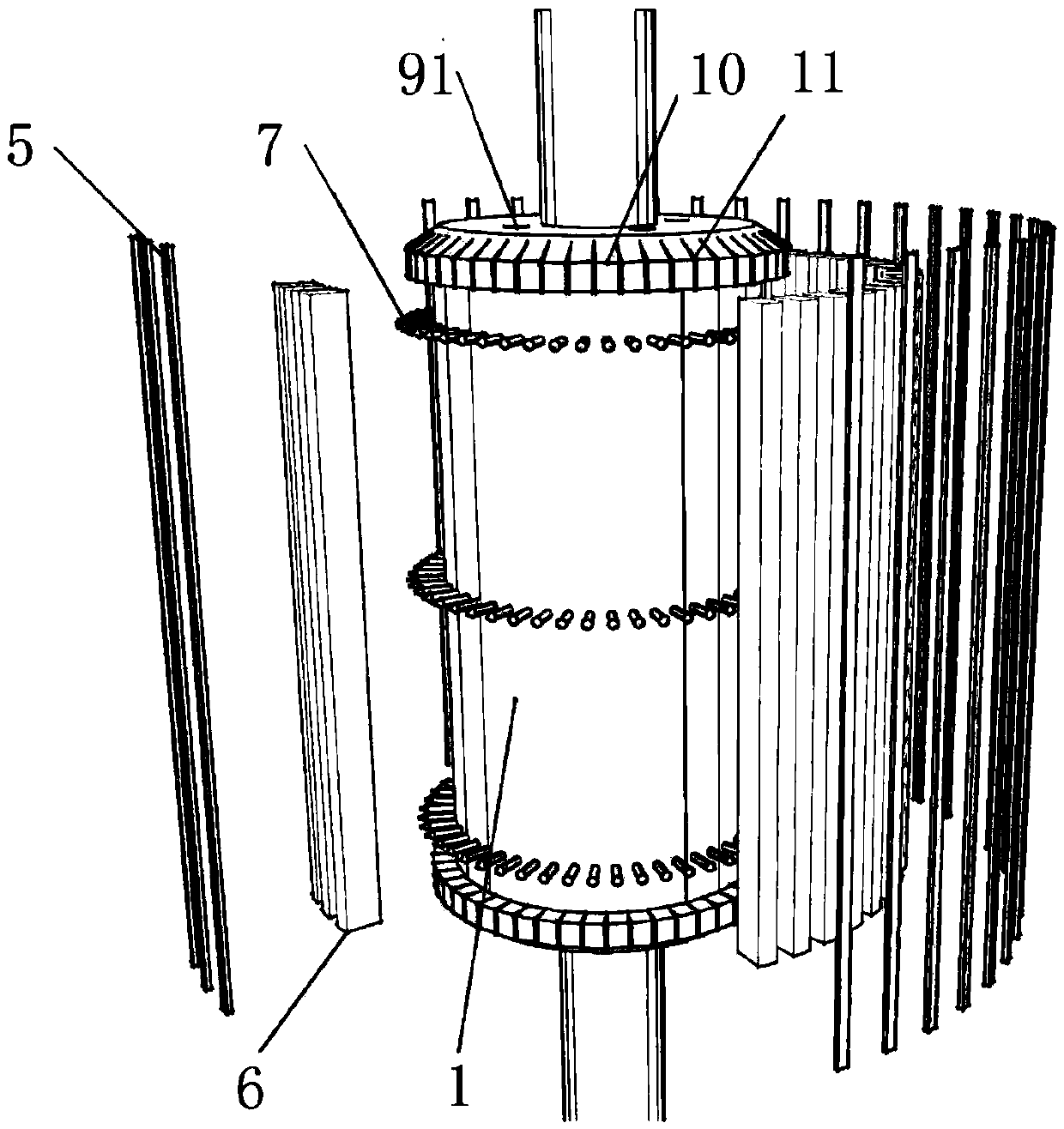

A short cutting tool holder

A knife holder and chopping technology, which is applied in the direction of manufacturing tools, glass manufacturing equipment, glass production, etc., can solve problems such as clogging, and achieve the effects of avoiding gaps or breaks, avoiding clogging, good elasticity and sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] As mentioned in the background art section, the current chopping knife holder is easy to cause blockage of sizing agent.

[0027] Based on the above research, the embodiment of the present invention provides a chopping tool holder. By setting the blade in the rubber groove, since the rubber itself has good elasticity and sealing performance, it can make the blade and the rubber groove The side walls are tightly fitted, and the sizing produced during chopping production is difficult to enter between the blade and the rubber groove, thereby avoiding clogging. At the same time, it can ensure that the blade has sufficient elastic deformation during chopping production, and can effectively avoid failures such as gaps or breaks caused by the blade relying on its own hardness to cut yarn.

[0028] In order to make the above objects, features and advantages of the present invention more comprehensible, the specific implementation manners of the present invention will be describ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com