Nano antifouling coating used for 3C electronic field and preparation and coating methods of same

A coating and nanotechnology, applied in anti-fouling/underwater coatings, coatings, paints containing biocides, etc., can solve the problems of easy loss of anti-fouling, long-lasting anti-fouling effect, selective spraying, etc. Flexible control, reasonable selective spraying, strong resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

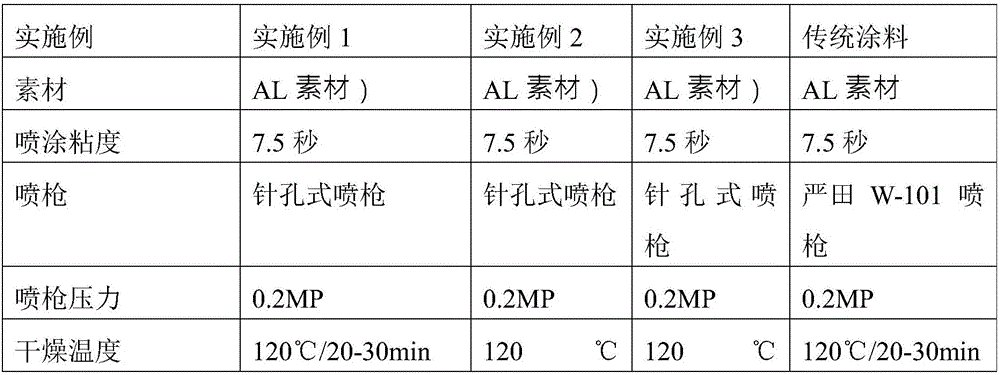

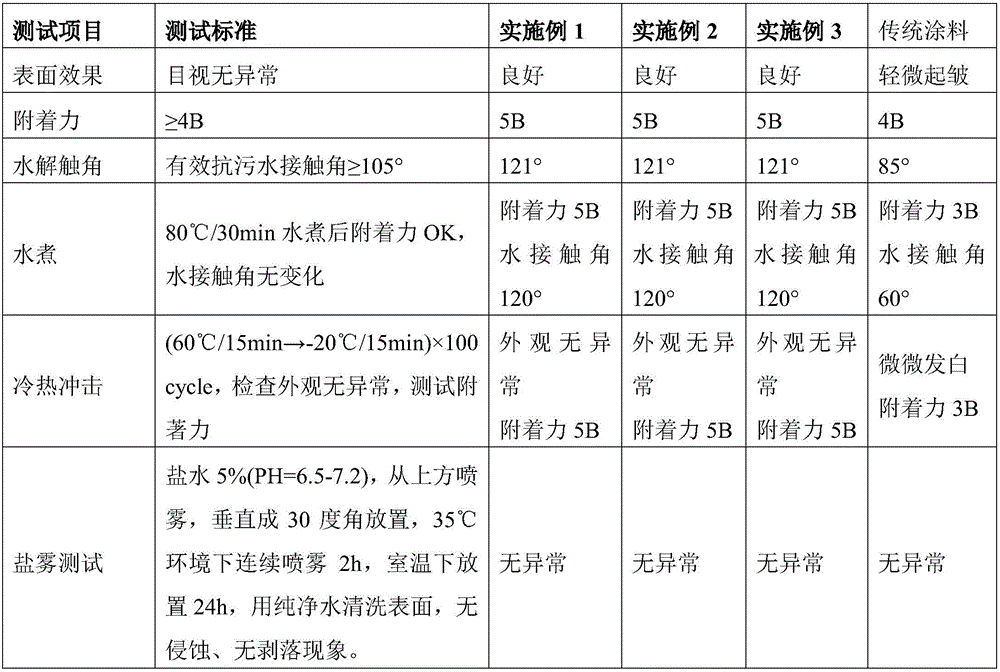

Embodiment 1

[0017] The applicant provides a nano antifouling coating, which comprises 1 weight part of fluorosilicon copolymer resin and 99 weight parts of ethyl nonafluorobutyl ether. The preparation method is as follows: put raw materials into a container, and stir evenly at a speed of 800 rpm until the paint is clear and transparent.

[0018] The coating method of the nano antifouling coating is as follows: using zero-atomization pinhole spraying equipment for selective coating, and the control equipment is as follows:

[0019] (1) Precisely control the valve, control the film thickness ≤ 10um;

[0020] (2) The outlet air pressure is 0.03Mpa;

[0021] (3) Atomization, adjust the width of the paint injection spray gun, atomize evenly, and make the injected particles uniform;

[0022] (4) The trajectory of the spray gun is controlled by programming.

Embodiment 2

[0024] The applicant provides a nano antifouling coating, which includes 2 parts by weight of fluorosilicon copolymer resin and 98 parts by weight of ethyl nonafluorobutyl ether. The preparation method is as follows: put raw materials into a container, and stir evenly at a speed of 1000 rpm until the paint is clear and transparent.

[0025] The coating method of the nano antifouling coating is as follows: using zero-atomization pinhole spraying equipment for selective coating, and the control equipment is as follows:

[0026] (1) Precisely control the valve, control the film thickness ≤ 10um;

[0027] (2) The outlet air pressure is 0.06Mpa;

[0028] (3) Atomization, adjust the width of the paint injection spray gun, atomize evenly, and make the injected particles uniform;

[0029] (4) The trajectory of the spray gun is controlled by programming.

Embodiment 3

[0031] The applicant provides a nano antifouling coating, which includes 1.5 parts by weight of fluorosilicon copolymer resin and 98.5 parts by weight of ethyl nonafluorobutyl ether. The preparation method is as follows: put raw materials into a container, and stir evenly at a speed of 1000 rpm until the paint is clear and transparent.

[0032] The coating method of the nano antifouling coating is as follows: using zero-atomization pinhole spraying equipment for selective coating, and the control equipment is as follows:

[0033] (1) Precisely control the valve, control the film thickness ≤ 10um;

[0034] (2) The outlet air pressure is 0.05Mpa;

[0035] (3) Atomization, adjust the width of the paint injection spray gun, atomize evenly, and make the injected particles uniform;

[0036] (4) The trajectory of the spray gun is controlled by programming.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com