Control method of urea injection in scr system

A technology of SCR system and control method, applied in instruments, machines/engines, mechanical equipment, etc., can solve problems such as difficulty in achieving control effects and system output limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

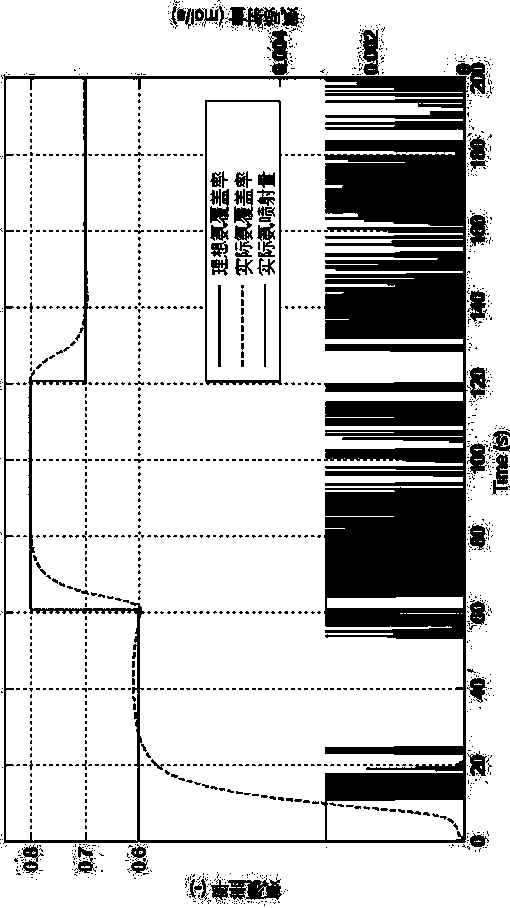

[0073] The main technical route of the present invention includes: according to the refinement and description of the control requirements and control problems of the urea SCR system, establishing a partial differential model; referring to the chemical reaction mechanism and mathematical approximation method, deducing the partial differential system predictive controller; summarizing the optimization problem, And the solution method of the optimization problem is given; finally, the control optimization algorithm that meets the requirements of the emission regulations is obtained. Its steps are:

[0074] a. Partial differential modeling of urea SCR system

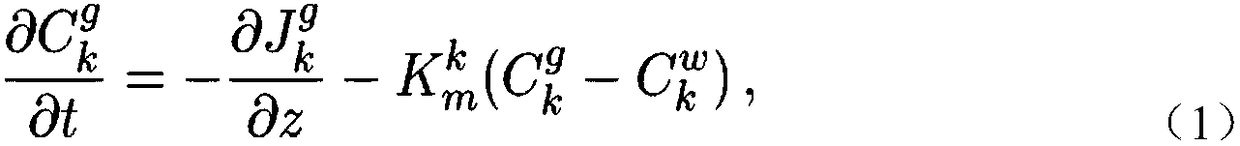

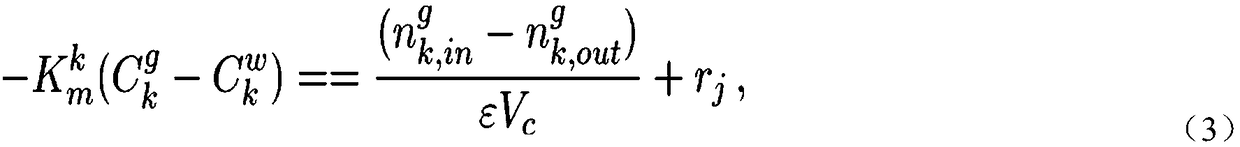

[0075] Based on the axial transport characteristics of the main substances in the urea SCR system, the dynamic transport reaction model is mainly referred to:

[0076]

[0077] Magnetic flux density formula:

[0078] J k = θ z C k , (2)

[0079] and a dynamic and steady-state assumption of the species concentration o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com