a dryer

A technology for dryers and drainage tanks, applied in steam boiler accessories, steam separation devices, components of steam boilers, etc., can solve the problems of reduced separation efficiency of dryers, low separation efficiency of dryers, and more water carried out, etc., to achieve Reduce production cost, avoid hydrophobic backspray, good hydrophobic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

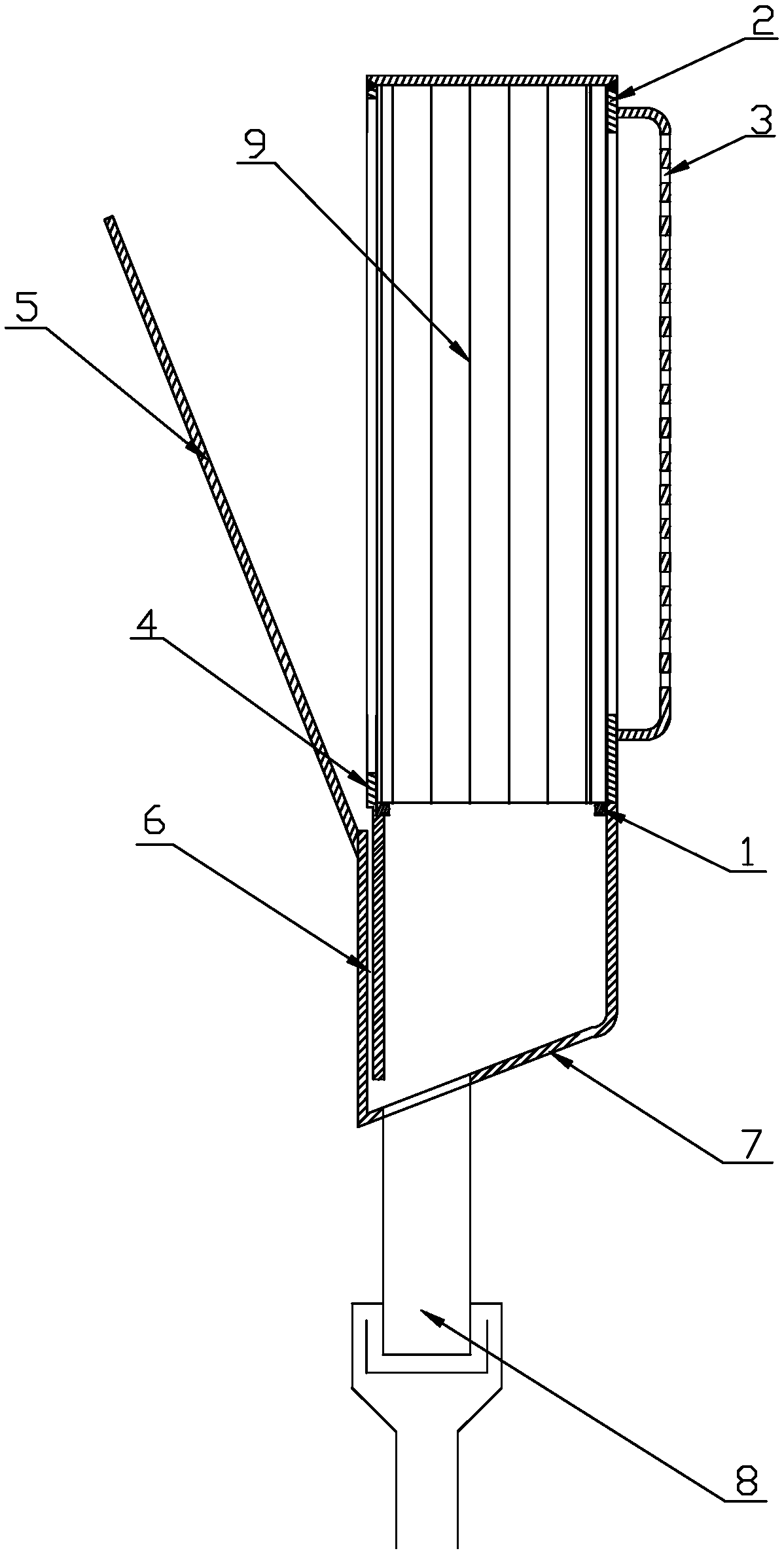

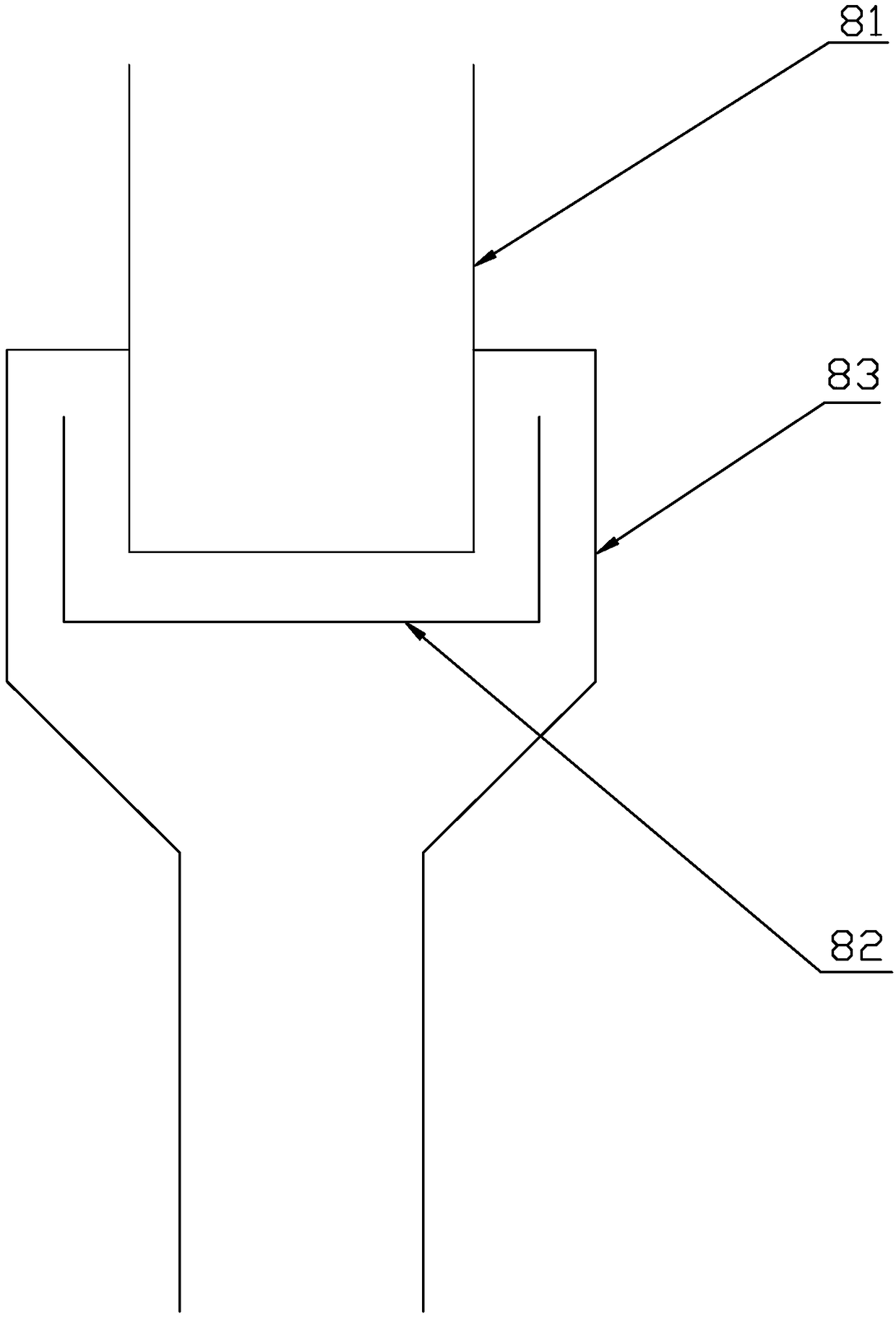

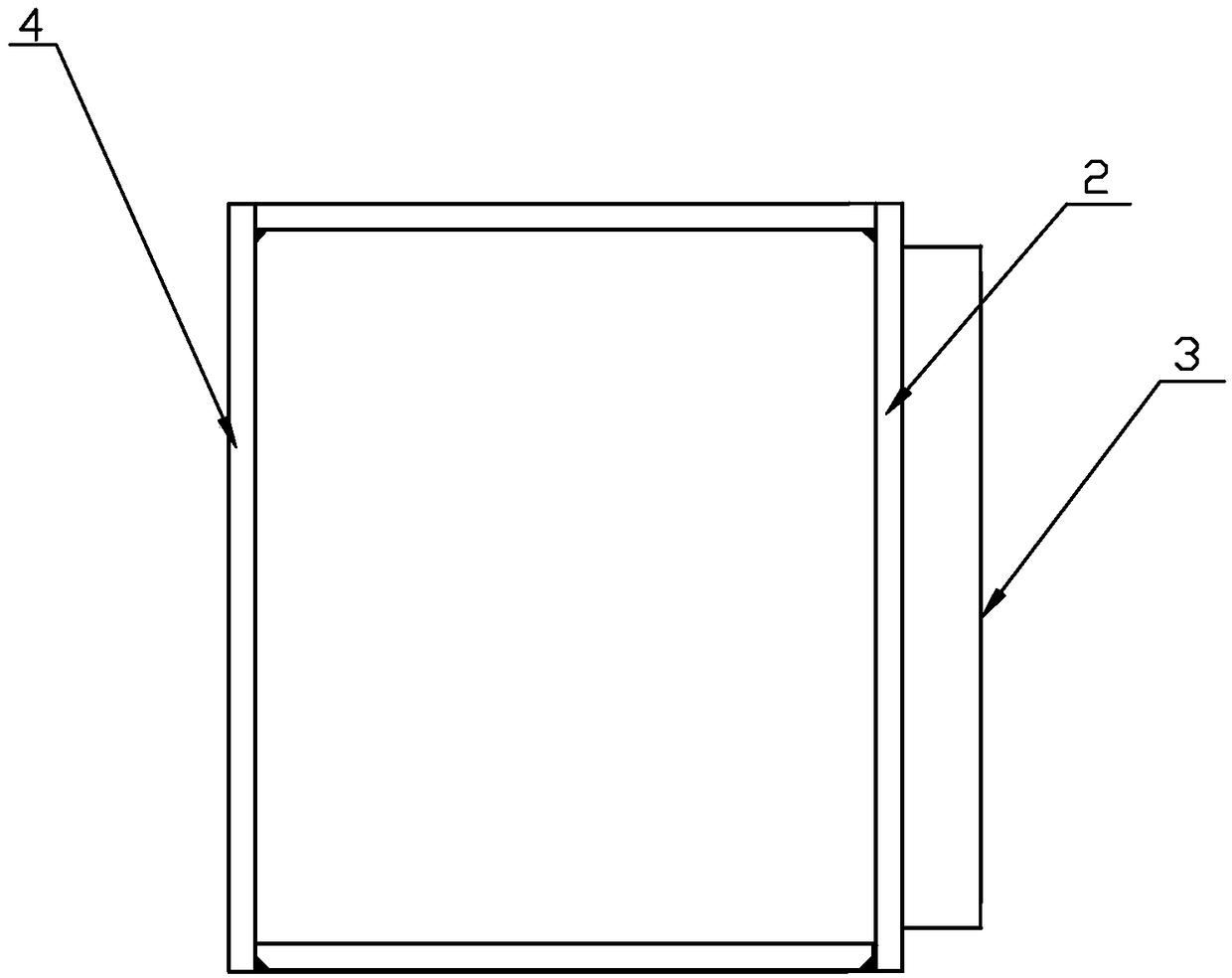

[0017] Reference Figure 1 ~ Figure 3 , The present invention is a dryer, including a dryer shell, a number of corrugated plates 9 fixed in the dryer shell, the other two sides of the dryer shell are respectively provided with steam outlet and inlet, the The steam inlet is provided with a perforated plate 3 fixedly connected to the dryer shell, and a drain box 7 is fixedly provided at the bottom of the dryer shell. The feature is that the bottom of the drain box 7 is inclined along the steam flow direction. The bottom of the drain tank 7 is provided with a water sealing device 8 to prevent backflow of the water body.

[0018] With the drainage box 7 at the bottom inclined along the steam direction and the water sealing device 8 to prevent backflow of water, the drainage volume of the dryer drainage structure along the steam flow direction is gradually increased, reducing the occurrence of the drainage being carried away by the steam again. In this way, a better hydrophobic effec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com