Preparation method of electrochromic thin film and electrochromic device

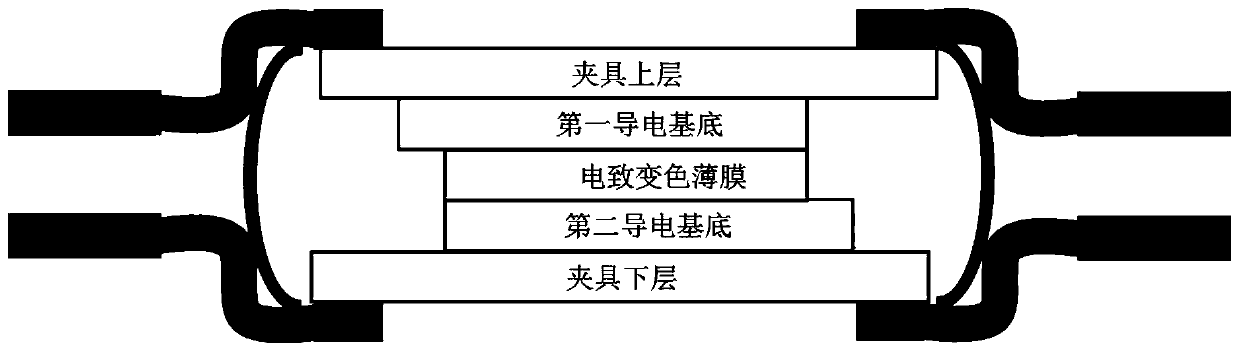

An electrochromic device and electrochromic technology, applied in the direction of instruments, nonlinear optics, optics, etc., can solve the problems of difficult electrochromic films, difficulty in producing large-sized, special-shaped color-changing windows, and high production costs. Achieve the effects of easy assembly of special shape devices, low cost, and easy post-processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present invention will be described below in conjunction with specific embodiments of the present invention, which are only used as explanations of the present invention rather than limitations.

[0031] A kind of electrochromic thin film of the present invention is prepared by following scheme:

[0032] 2g of polyvinyl alcohol, 0.5g of polymethyl methacrylate, put into ethanol / N,N-dimethylformamide mixed solvent (the amount of ethanol is 20mL, and the amount of N,N-dimethylformamide is 4mL) , were poured into a round bottom flask together and a magnetic stir bar was added. Place the round bottom flask in a collector stirrer, turn on the stirring function and set the temperature to 80°C to start heating. After the solid substance is completely dissolved into the liquid to form a viscous clear solution A, stop heating and cool to room temperature.

[0033] Add 5mL of γ-butyrolactone (or ethanol, propylene carbonate, ethylene carbonate or ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com