Trotting horse lamp type sewage plant lifting pump lifetime extension control device and control method

A control device and lift pump technology, which is applied in the direction of program control, program control, and electrical program control in the sequence/logic controller, can solve the problems of reduced life of the lift pump, long continuous use time, and many startup times, and achieve Reduce energy consumption, convenient operation, and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

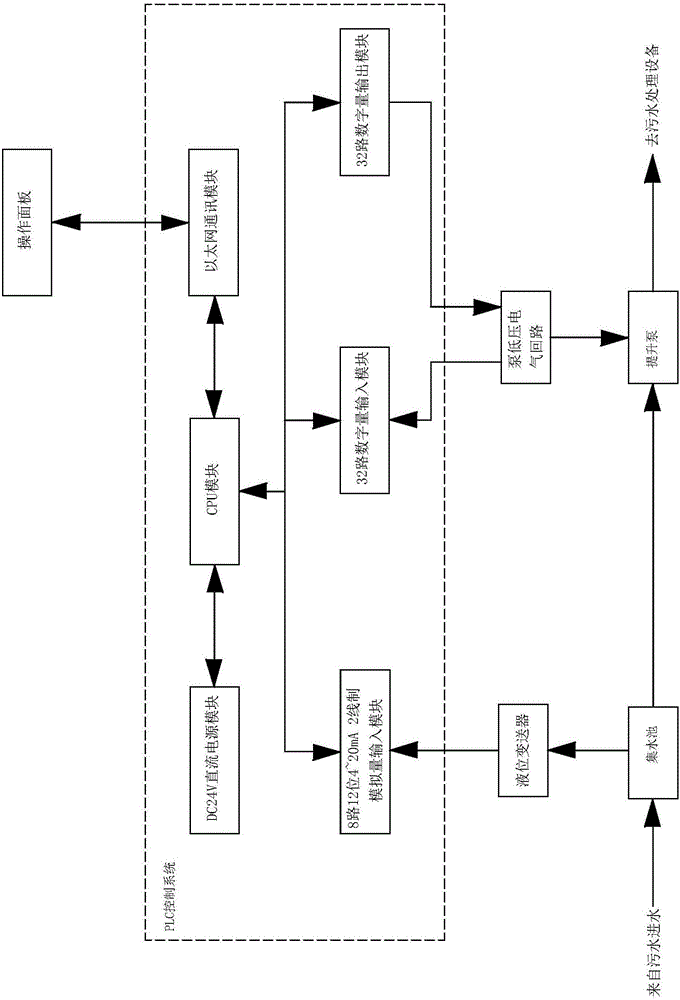

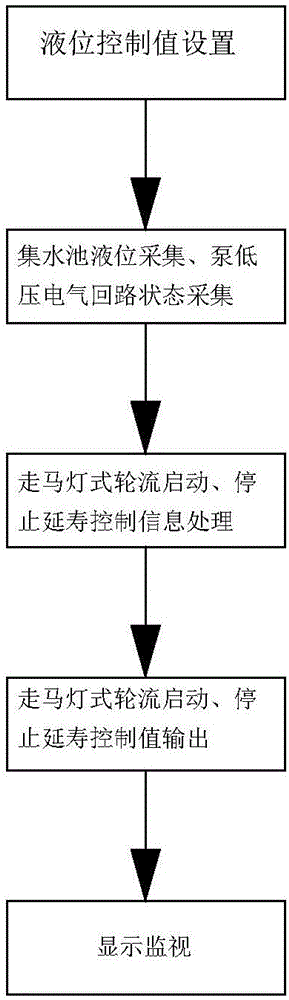

[0021] Such as figure 1 As shown in the present invention, the revolving lantern type sewage plant lifting pump life extension control device includes a PLC control system, an operation panel, a liquid level transmitter, and a plurality of low-voltage electrical circuits for pumps. The liquid level transmitter is arranged in the sump of the sewage plant. The lift pumps are connected between the sump of the sewage plant and the sewage treatment equipment, and each lift pump is connected to a pump low-voltage electrical circuit. The PLC control system includes a CPU module and a DC24V DC power supply module connected to the CPU module, an Ethernet communication module, an analog input module, multiple digital input modules, and multiple digital output modules. The electrical circuit is also respectively connected with the digital input module and the digital output module. In order to simply illustrate the control device, only one lift pump, one pump low-voltage electrical circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com