Flame-retardant styrene resin composition and preparation method thereof

A technology of styrene resin and styrene copolymer, applied in the field of flame retardant styrene resin composition and its preparation, can solve the problems of difficult injection molding, poor apparent quality, low melt index and the like, and can reduce the injection temperature , the effect of reducing production costs and simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

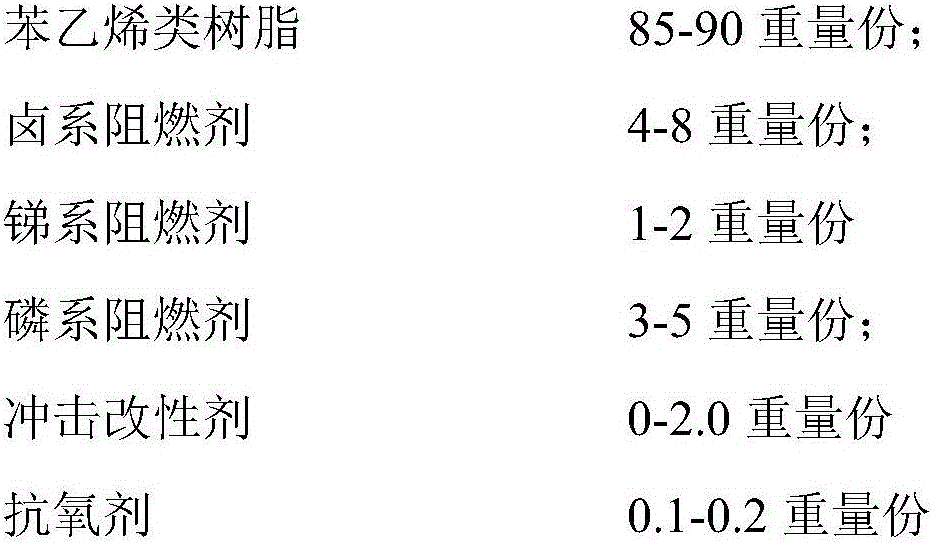

[0037] The components and mass fraction of the styrene resin composition are:

[0038]

[0039] in:

[0040] Styrene resin is Taihua's high-impact polystyrene 8250 resin;

[0041] The halogenated flame retardant is bromotriazine;

[0042] The antimony-based flame retardant is antimony trioxide;

[0043] The phosphorus flame retardant is PX220 of Wansheng;

[0044] Antioxidant is Irganox 1010.

Embodiment 2

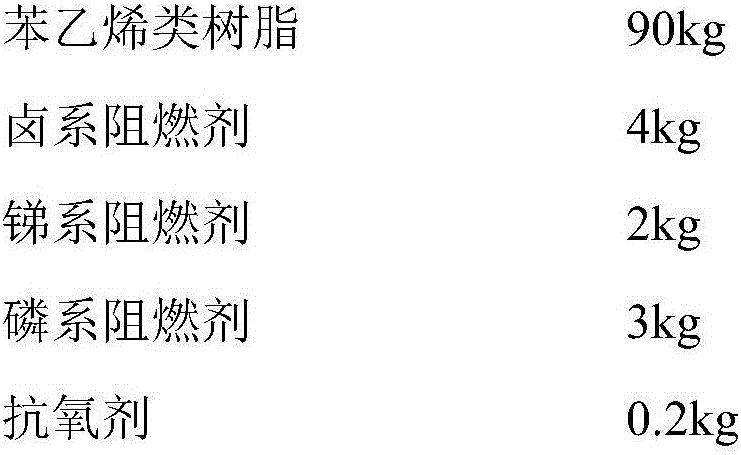

[0046] The components and mass fraction of the styrene resin composition are:

[0047]

[0048] in:

[0049]Styrene resin is Taihua's high-impact polystyrene 8250 resin;

[0050] The halogenated flame retardant is Yabao's Tetrabromobisphenol A;

[0051] The antimony-based flame retardant is a mixture of antimony trioxide and sodium antimonate;

[0052] The phosphorus flame retardant is PX220 of Wansheng;

[0053] Antioxidant is Irganox 1076.

Embodiment 3

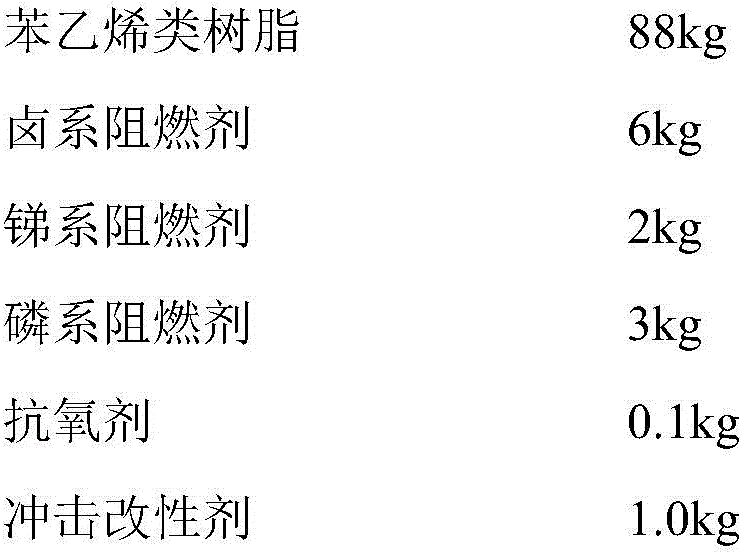

[0055] The components and mass fraction of the styrene resin composition are:

[0056]

[0057] in:

[0058] The styrene resin is Kumho's high-impact polystyrene 425TVL resin;

[0059] The halogenated flame retardant is Yabao's decabromodiphenylethane;

[0060] The antimony-based flame retardant is antimony trioxide;

[0061] The phosphorus-based flame retardant is Wansheng's triphenyl phosphate;

[0062] Antioxidant is Irganox 1098.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com