Anti-pollution dry spinning device

A dry spinning and anti-pollution technology, applied in the field of chemical fiber spinning, can solve the problems of slow solvent volatilization, large environmental pollution, and low work efficiency, and achieve the effects of accelerating work efficiency, increasing spinning speed, and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

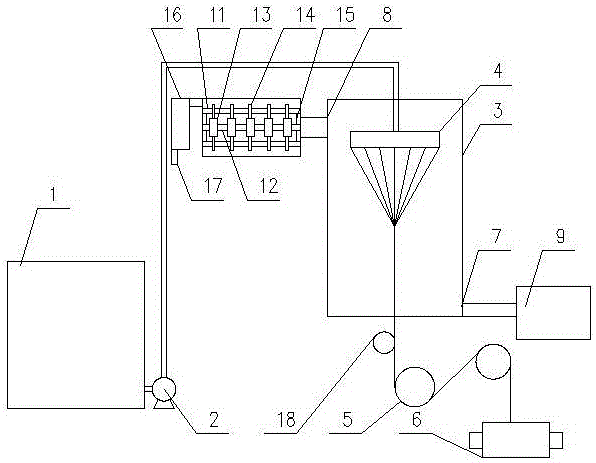

[0022] Such as figure 1 As shown, the anti-pollution dry spinning device of this embodiment includes a spinning solution storage tank 1, and a spinning pump 2 is arranged inside the spinning solution storage tank, and the spinning pump is installed on the The spinneret 4 inside the tunnel 3, the bottom of the tunnel is connected to the winding drum 6 through the godet 5, the tunnel is provided with an air inlet 7 and an air outlet 8, and the air inlet is connected to the hot gas through a pipeline. The supply device 9, the gas outlet is connected to the volatile solvent purification device through a pipeline.

[0023] In the anti-pollution dry spinning device described in this embodiment, the volatile solvent purification device includes a purification box 10 connected to the air outlet through a pipeline, and the two sides of the box inside the purification box are provided with Two parallel anode brackets 11, a cathode plate 12 is arranged between the two parallel anodes, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com