Special paper making compound sterilizing mildew inhibitor

A technology of bactericidal and antifungal agent and special paper, which is applied in the direction of adding anti-biological reagents and paper, can solve the problems of unsuitability and loss of effect of bactericidal and antifungal agents, and achieve the effect of broadening the bactericidal spectrum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

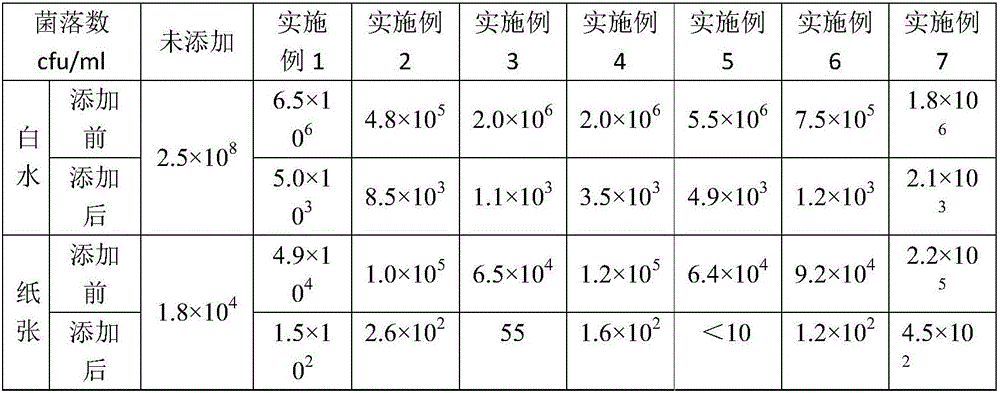

Examples

preparation example Construction

[0014] The preparation method of the papermaking bactericidal antifungal agent of the present invention is as follows: 2,4-dichloro-3,5-dimethylphenol, 2-methyl-1-isothiazolin-3-one, phenoxyethanol and certain Mix and stir a certain amount of solvent, heat to 60°C, dissolve evenly, add emulsifier, stir evenly, add the rest of water, continue stirring, and cool to obtain the product.

[0015] The sterilization and antifungal agent for papermaking of the present invention is stable in property, and different application methods can be adopted according to different paper requirements, and the required environment is 10°C-200°C, pH 1.5-12.5.

Embodiment 1

[0017] The papermaking bactericidal antifungal agent described in the present embodiment, concrete composition is as follows:

[0018] Mix and stir 10 parts of 2,4-dichloro-3,5-dimethylphenol, 8 parts of 2-methyl-1-isothiazolin-3-one, 12 parts of phenoxyethanol and 12 parts of solvent, and heat to 60°C, dissolve evenly, add 7 parts of emulsifier, stir evenly, add the remaining 51 parts of water, continue stirring, and cool to obtain the product.

[0019] Wherein, the solvent is composed of ethylene glycol and 3-methyl-1-butanol with a mass ratio of 2:1; the emulsifier is composed of polyethylene glycol 400 and lauryl polyoxyethylene ether with a mass ratio of 1:1 Composition of sodium sulfate.

Embodiment 2

[0021] The papermaking bactericidal antifungal agent described in the present embodiment, concrete composition is as follows:

[0022] Mix and stir 18 parts of 2,4-dichloro-3,5-dimethylphenol, 7 parts of 2-methyl-1-isothiazolin-3-one, 5 parts of phenoxyethanol and 15 parts of solvent, and heat to 60°C, dissolve evenly, add 6 parts of emulsifier, stir evenly, add the remaining 49 parts of water, continue stirring, and cool to obtain the product.

[0023] Wherein, the solvent is composed of ethylene glycol dimethyl ether and cyclohexanol with a mass ratio of 1:1; the emulsifier is composed of polyethylene glycol 400 and sodium hexadecyl diphenyl ether disulfonate with a mass ratio of 1:2 composition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com