Walking steering mechanism and seepage-preventing ditch cast-in-situ forming machine

A technology of steering mechanism and molding machine, which is applied in water conservancy projects, artificial waterways, buildings, etc., and can solve problems such as inability to realize steering work, inability to fully utilize the working potential of anti-seepage canal cast-in-place molding equipment, complex steering mechanisms, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

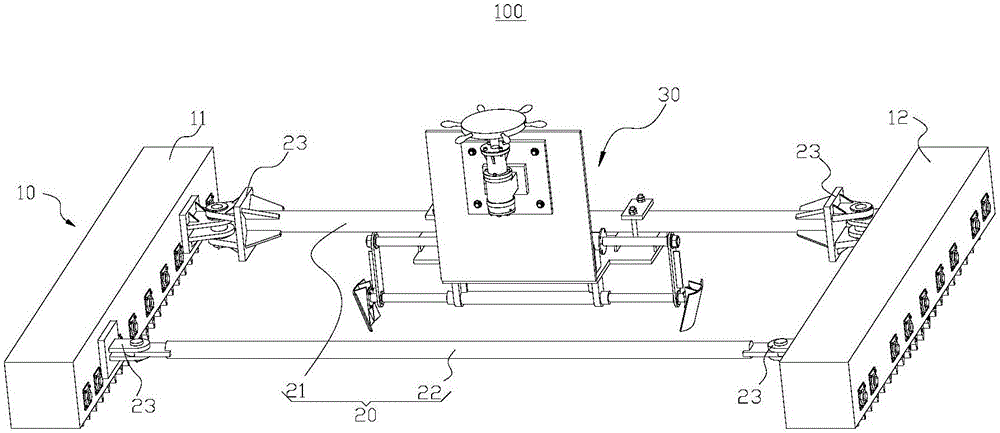

[0035] like figure 1 As shown, this embodiment provides a walking steering mechanism 100 , including a walking assembly 10 , a connecting assembly 20 and a driving device 30 .

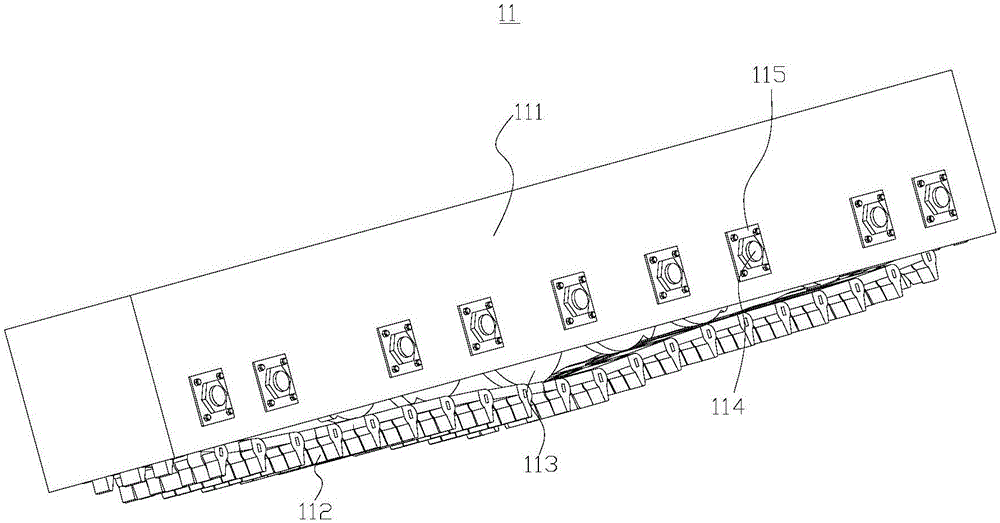

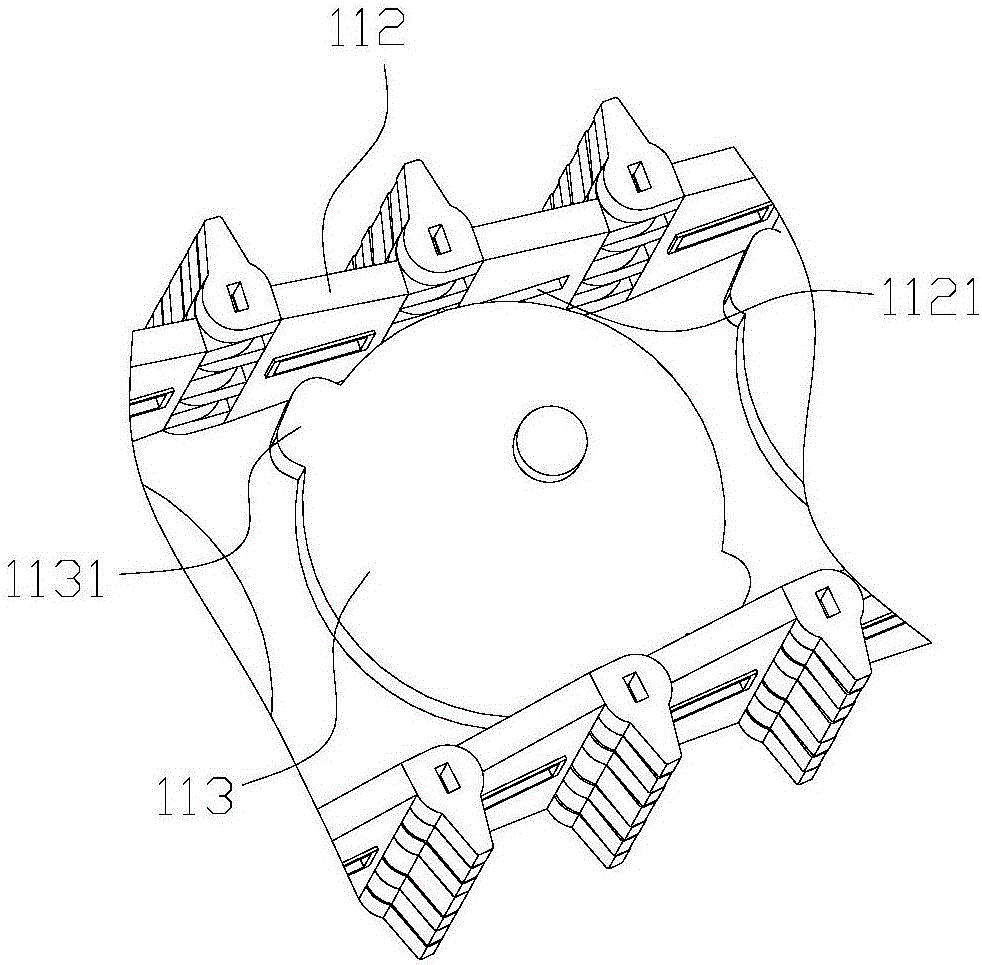

[0036] Specifically, the walking assembly 10 includes a first walking part 11 and a second walking part 12 . like figure 2 As shown, the first running part 11 includes a frame body 111 , caterpillar belts 112 and several runners 113 . The frame body 111 is a cuboid structure, which forms a receiving cavity with an open bottom, and a plurality of bearing seats 115 are provided on both side walls of the frame body 111 in the width direction. The runners 113 are located in the receiving cavity, and the runners 113 are all connected to the frame body 111 through the rotating shaft 114 , and the two ends of the rotating shaft 114 are connected to the bearing seats 115 on the frame body 111 through bearings. The track 112 is partially located in the accommodation cavity, and the frame body 111 can play a...

Embodiment 2

[0056] like Image 6 As shown, the difference between this embodiment and Embodiment 1 is that the first rib 3312 in the first toggle member 331 and the first movable body 3222 in the two-way moving rod 322 are rotationally connected by a pin shaft, and the second toggle The second rib 3322 in the member 332 is rotatably connected with the second movable body 3223 in the two-way moving rod 322 through a pin shaft. A first hydraulic cylinder 34 is provided between the first scraper 3311 and the first movable body 3222. One end of the first hydraulic cylinder 34 is hinged to the first scraper 3311, and the other end of the first hydraulic cylinder 34 is hinged to the first movable body 3222. . A second hydraulic cylinder 35 is provided between the second scraper 3321 and the second movable body 3223, one end of the second hydraulic cylinder 35 is hinged to the second scraper 3321, and the other end of the second hydraulic cylinder 35 is hinged to the second movable body 3223 ....

Embodiment 3

[0060] like Figure 7 As shown, this embodiment provides an anti-seepage canal cast-in-place forming machine 200, which includes a forming machine body 210 and the travel steering mechanism 100 in the above-mentioned embodiments.

[0061] Wherein, the molding machine body 210 can complete the casting work on the channel, so that the channel will not leak. The specific structure of the molding machine body 210 is the same as that of the prior art. Of course, the molding machine body 210 should be equipped with an oil supply system for supplying oil to each hydraulic component.

[0062] The molding machine body 210 is placed on the first running part 11 and the second running part 12, and the first running part 11 and the second running part 12 are both rotatably connected with the molding machine body 210, that is, the molding machine body 210 can move relative to the first running part 11 and the second running part 12 rotate in the horizontal plane.

[0063] The anti-seepag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com