Sliding yawing braking system for wind generating set

A technology for wind turbines and braking systems, which is applied to wind turbines, wind turbine control, wind power generation, etc., can solve the problems of heavy handling and disassembly of the caliper body, easy loosening of adjustment bolts, and difficulty in operation and maintenance. Installation and maintenance, avoiding the work of removing high-strength bolts, the effect of reducing the workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

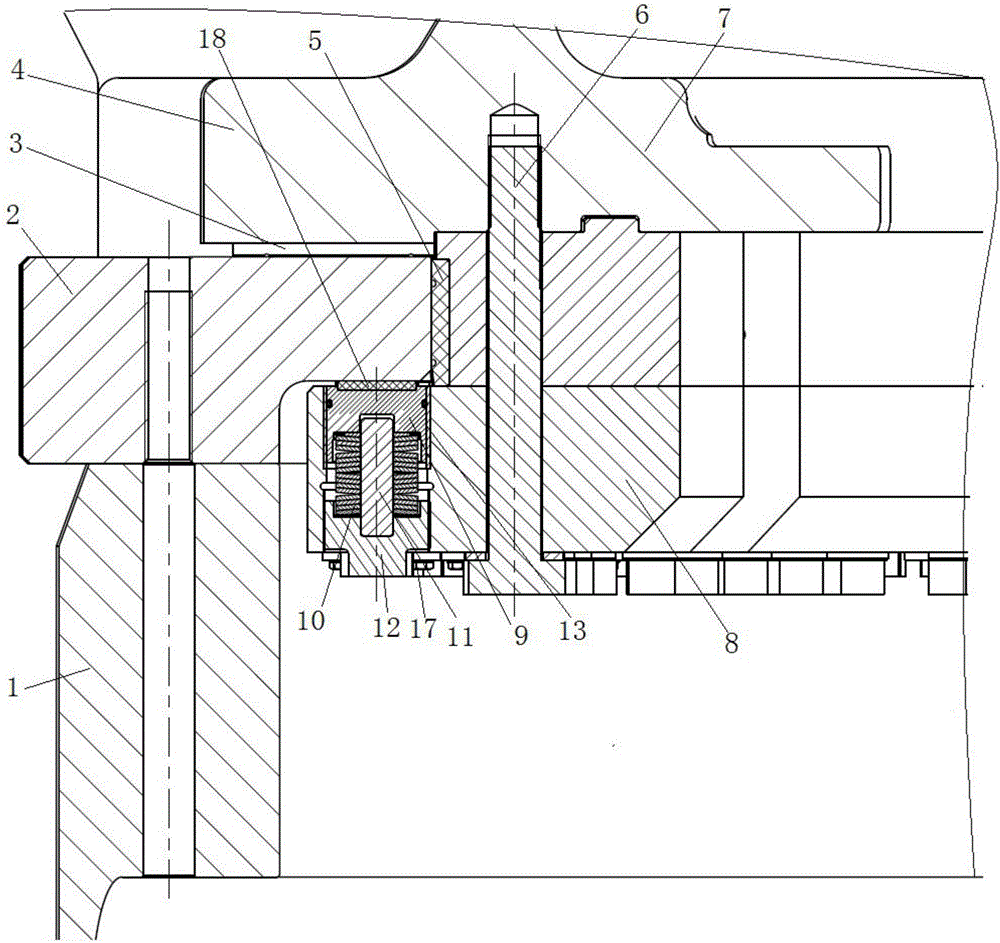

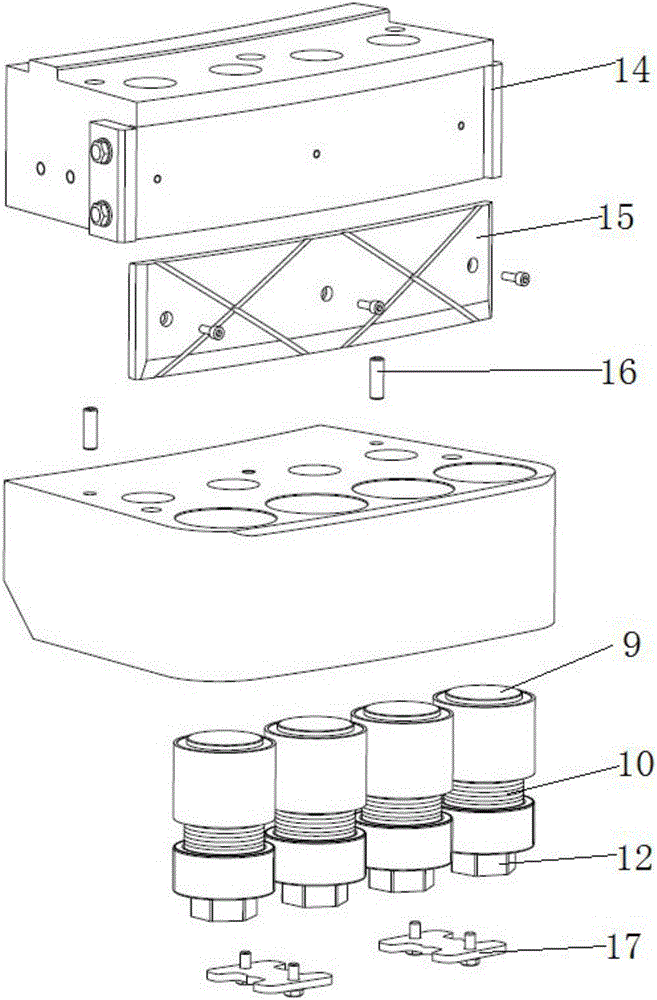

[0018] like figure 1 , as shown in 2, a novel sliding yaw braking system for wind turbines mainly includes: tower top flange 1, yaw ring gear 2, upper friction plate 3, nacelle bottom plate 4, radial friction plate 5, high Strength bolt 6, upper caliper body 7, lower caliper body 8, piston assembly 9, disc spring group 10, guide rod 11, adjusting nut 12, bushing 13, baffle plate 14, screw 15, positioning pin 16, locking plate 17 , Lower friction plate 18. The upper caliper body 7 and the lower caliper body 8 are connected to the nacelle floor 4 through high-strength bolts 6, and the upper caliper body 7 and the lower caliper body 8 are connected and positioned by positioning pins 16, and are coupled with the yaw ring gear 2 at the same time , used to prevent the cabin from falling; the upper friction plate 3 is installed between the cabin floor 4 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com