Hot working sequential controlled opening ignition spreading device

A timing control and throwing device technology, applied in the field of pyrotechnics, to achieve the effect of reducing requirements and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

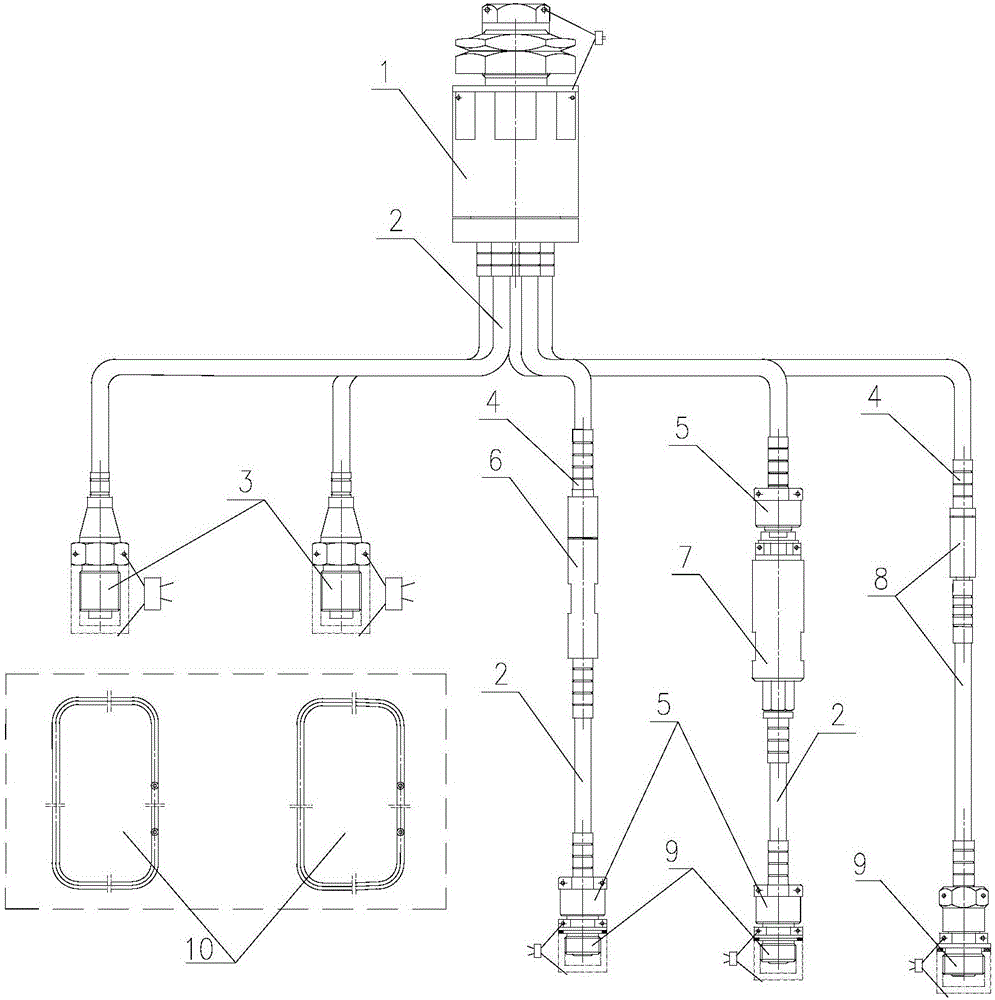

[0028] Such as figure 1 As shown, the present invention includes a manifold 1, a restricted detonating cord 2, a first output joint 3, a second output joint 4, a third output joint 5, a first delay tube 6, a second delay tube 7, and a delay cord 8 , Bulkhead igniter 9 and cutting cord assembly 10. Manifold 1 is fixed on the bomb through external threads, and is connected to the input element of the upper stage through internal threads, and is used to convert one signal into multiple signals (five in the figure) through the internal cluster structure after receiving the detonation signal, and The signal is transmitted to the output joint and delay structure through the restrained detonating cord 2. The timing control of the device is realized through the first delay tube 6, the second delay tube 7, and the delay cable 8. The first delay tube 6, the second delay tube 7, and the delay cable 8 are all connected to the output joints in the device through threads. The cutting cabl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Linear density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com