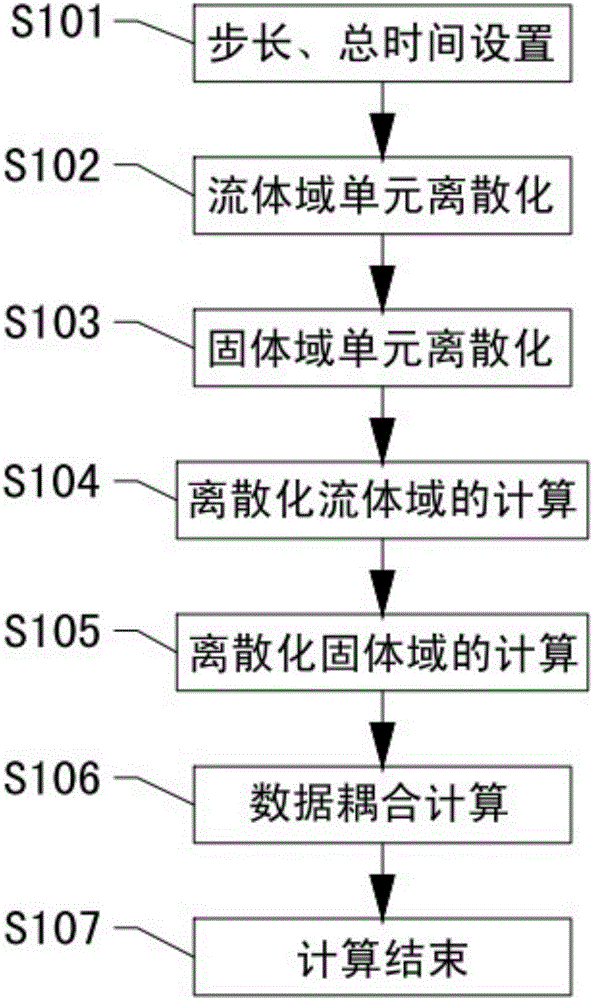

Multiple fluid-solid coupling calculation method for tail bearing-rotor system

A fluid-structure coupling and calculation method technology, applied in calculation, design optimization/simulation, special data processing application, etc., can solve the problem of weak foundation of multi-field coupling working process simulation, low calculation accuracy of fluid domain, stern bearing and propeller shaft system Problems such as inaccurate numerical simulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0118] Embodiment 1: The multiple fluid-solid coupling calculation process of two four-blade tail bearing-rotor systems is the best embodiment of the present invention.

[0119] 1.1, set the unit time step Δt 1 , the total time to calculate T 1 ;

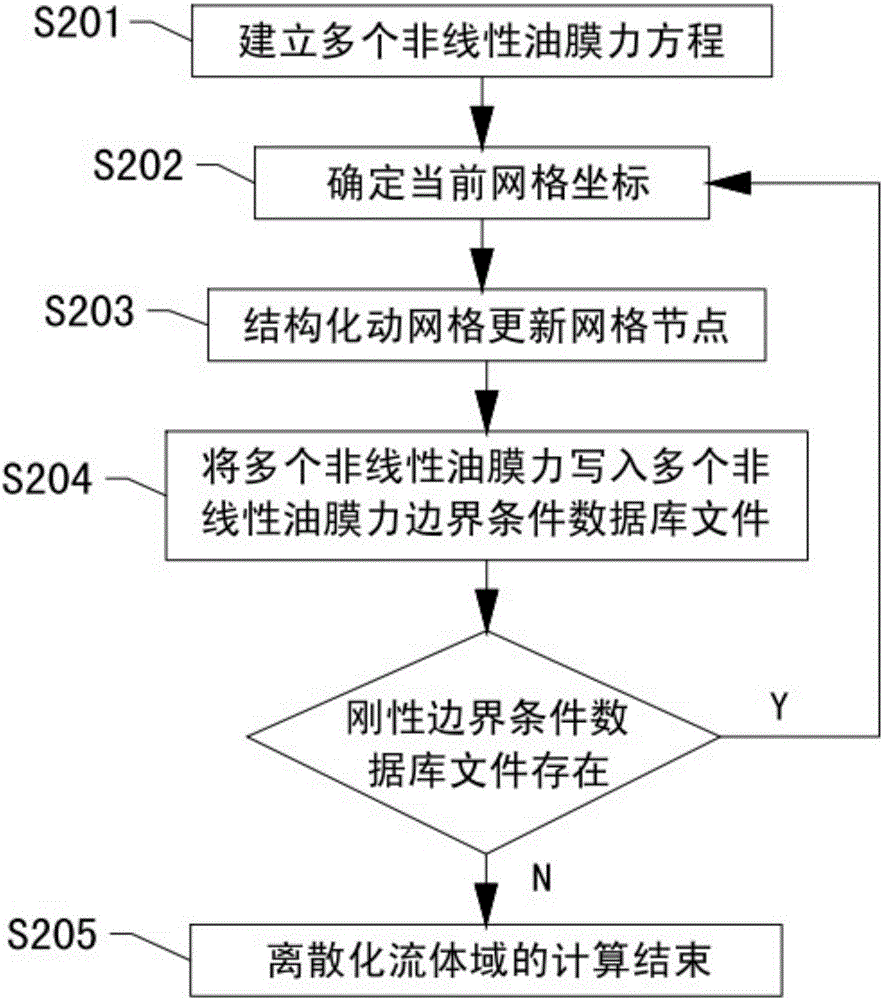

[0120] 1.2. Using computational fluid dynamics (CFD) software, the numerical calculation of two four-lobe tail bearings is carried out at the same time, and the nonlinear oil film force (Fx 1 , Fy 1 ), (Fx 2 , Fy 2 );

[0121] 1.3, the Δt 1 , the current calculation time T d1 , (Fx 1 , Fy 1 ), (Fx 2 , Fy 2 ) is written into two four-blade tail bearing boundary condition database files as the nonlinear oil film force boundary condition calculated in the discretized solid domain;

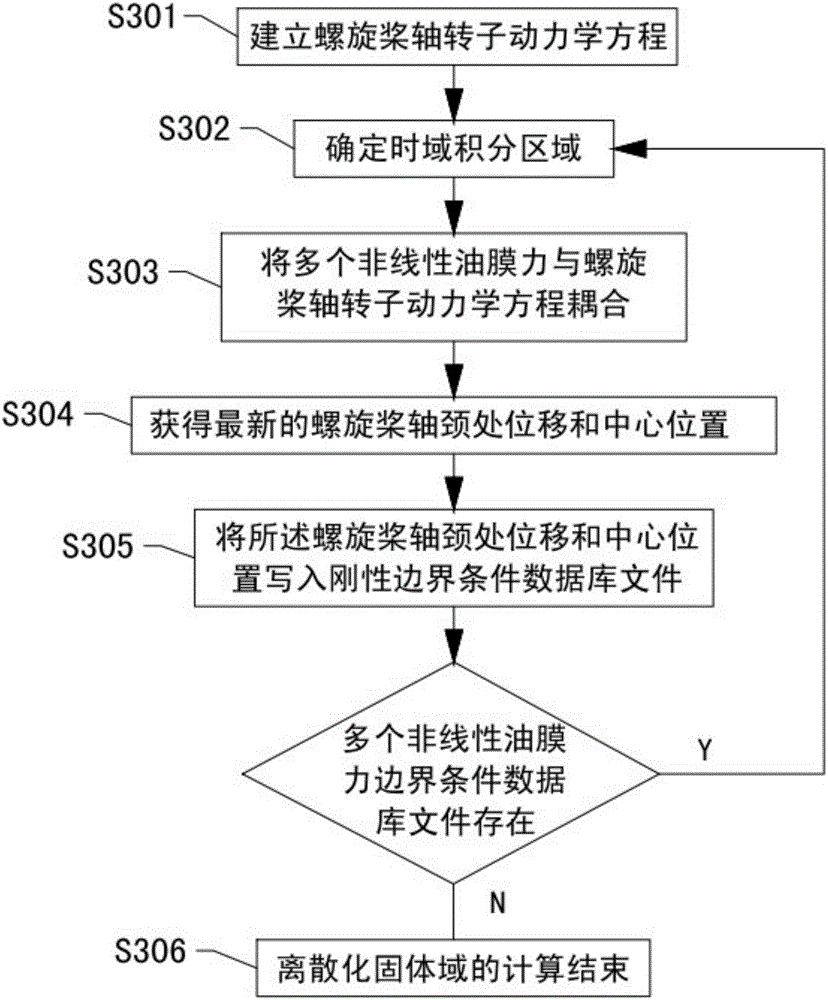

[0122] 1.4, discretized solid domain calculation to establish propeller shaft rotor dynamics equation:

[0123] M s ·· + C s · + K s = ...

Embodiment 2

[0162] Embodiment 2: Multiple fluid-solid coupling calculation process of the three elliptical stern bearing-rotor system.

[0163] 2.1, set the unit time step Δt 2 , the total time to calculate T 2 ;

[0164] 2.2. Using computational fluid dynamics CFD software, numerical calculations are carried out on three elliptical tail bearings at the same time, and the nonlinear oil film force (Fx 5 , Fy 5 ), (Fx 6 , Fy 6 ), (Fx 7 , Fy 7 );

[0165] 2.3, the Δt 2 , the current calculation time T d2 , (Fx 5 , Fy 5 ), (Fx 6 , Fy 6 ), (Fx 7 , Fy 7 ) is written into three elliptical stern bearing boundary condition database files as the nonlinear oil film force boundary condition calculated in the discretized solid domain;

[0166] 2.4, discretized solid domain calculation to establish propeller shaft rotor dynamics equation:

[0167] M s ·· + C s · + K s = B ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com