Winding process of external winding of low-frequency mute high-efficiency DC motor

A technology of DC motors and winding groups, which is applied in the direction of electric components, manufacturing motor generators, electrical components, etc. It can solve the problems of inability to realize speed conversion, poor heat dissipation effect, easy to burn circuit boards, etc., and achieve excellent heat dissipation effect, Small size, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in combination with specific embodiments.

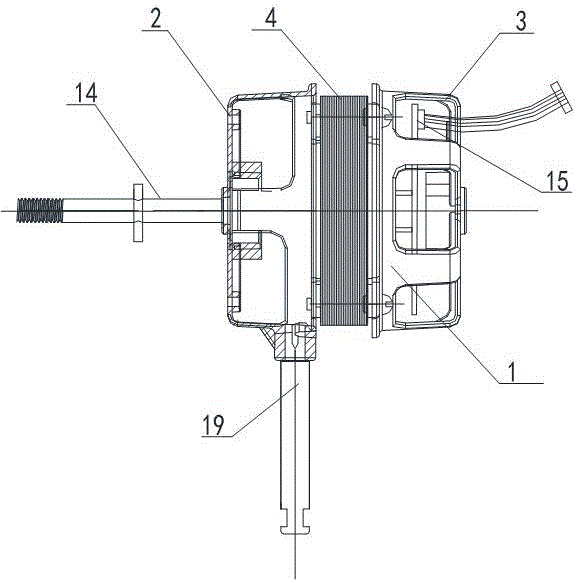

[0027] A low-frequency quiet high-efficiency DC motor outer winding process,

[0028] The first step is to manufacture the inner core of the iron core, stamp the thin iron sheet into one piece, and then continue to the next step;

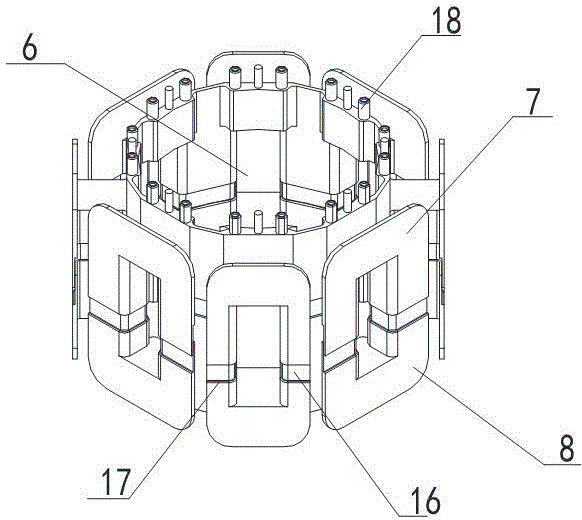

[0029] The second step is to separate the plastic bracket into an upper bracket and a lower bracket, move the upper bracket to the upper side of the inner core of the iron core, move the lower bracket to the lower side of the inner core of the iron core, and align it with the socket of the inner core of the iron core. position, combine the upper bracket and the lower bracket to form a plastic bracket, and then proceed to the next step;

[0030] The third step is to insert the pin wire into the pin hole on one side of the plastic bracket, and then proceed to the next step;

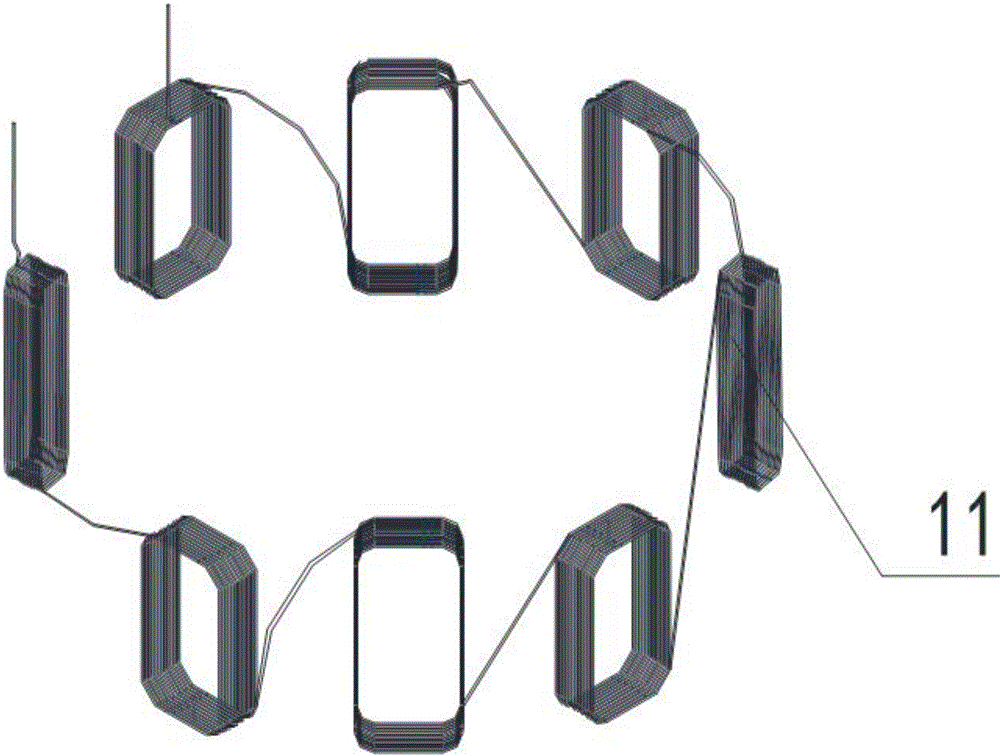

[0031] The fourth step is to start winding on several outer winding g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com