A nozzle device with wrapping function

A nozzle and functional technology, applied in the fields of medical science, prosthesis, additive processing, etc., to improve the adhesion rate and reduce the mortality rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further illustrate the feasibility, practicability and ease of operation of the invention patent, the invention patent will be described in detail in combination with schematic diagrams.

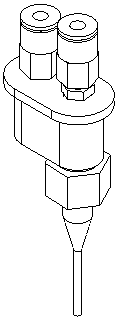

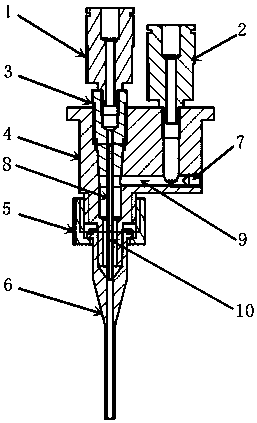

[0024] A sprinkler device with wrapping function, such as figure 1 and 2 As shown, it includes a quick connector 1, a quick connector 2, a cone positioning member 3, a nozzle body 4, a set nut 5, a needle 6, a sealing screw 7, a capillary 8, an outer cavity 9, and an inner cavity 10. The nozzle body 4 and the cone positioning part 3 are fixed by threads and the concentricity requirements are maintained by the cone positioning. This structure can prevent the wrapping material from leaking out; The design realizes the positioning of the needle head 6 so as to meet the requirement of coaxiality; the sealing screw 7 plays a role of sealing to prevent leakage of wrapping materials or active biological materials.

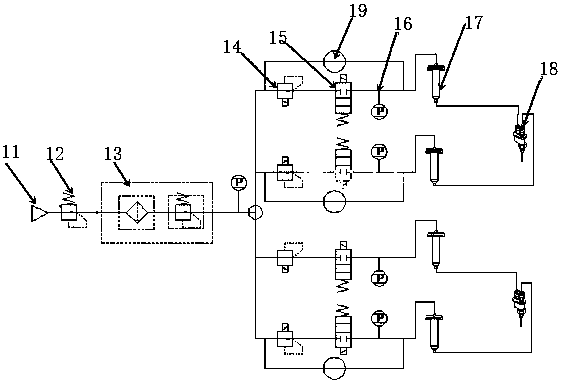

[0025] image 3 It is the air pressure automatic feedback adj...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com