Chemical stirring tank capable of achieving premixing and being conveniently cleaned

A mixing tank and pre-mixing technology, which is applied in the field of chemical mixing tanks, can solve the problems of reducing production efficiency, increasing labor intensity of workers, and insufficient mixing of materials, so as to speed up work efficiency, improve cleaning efficiency and cleaning quality, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

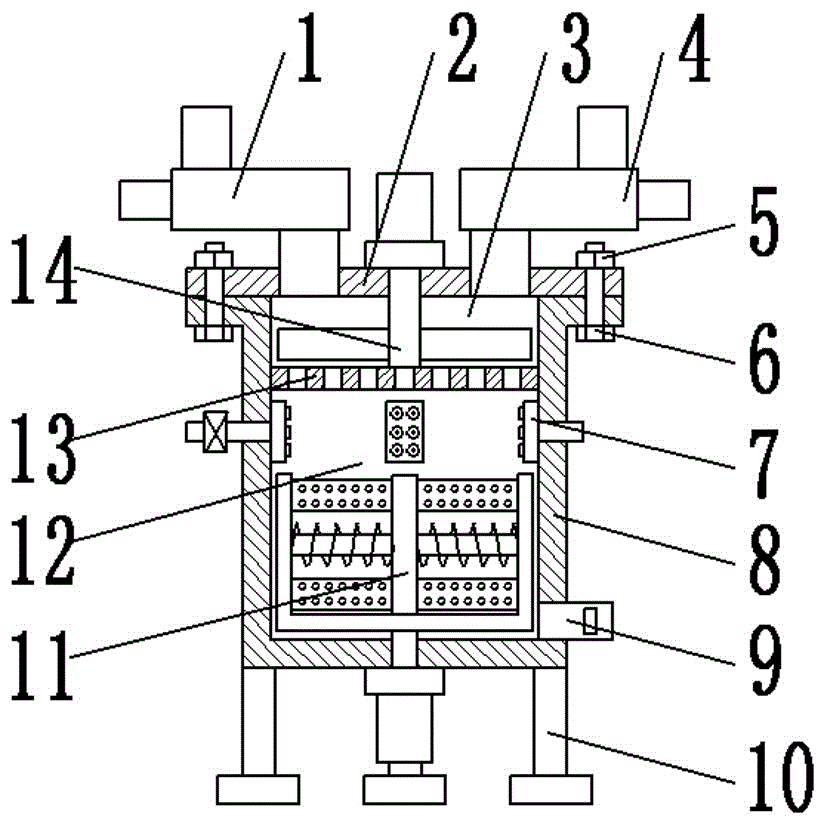

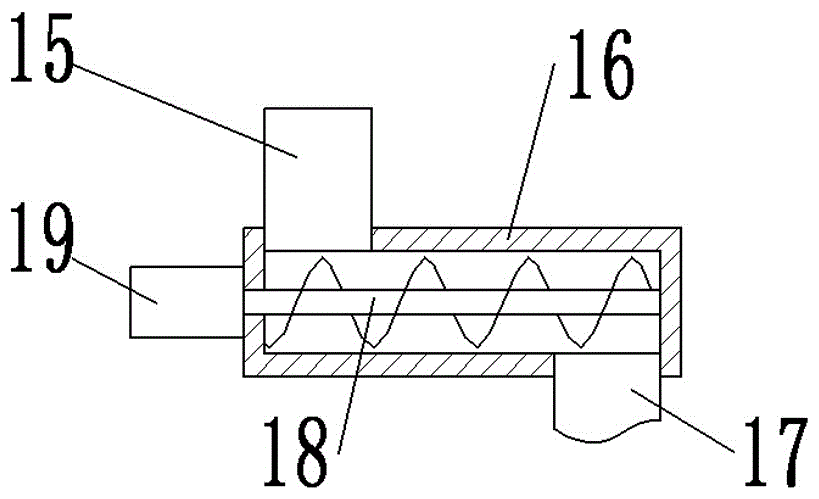

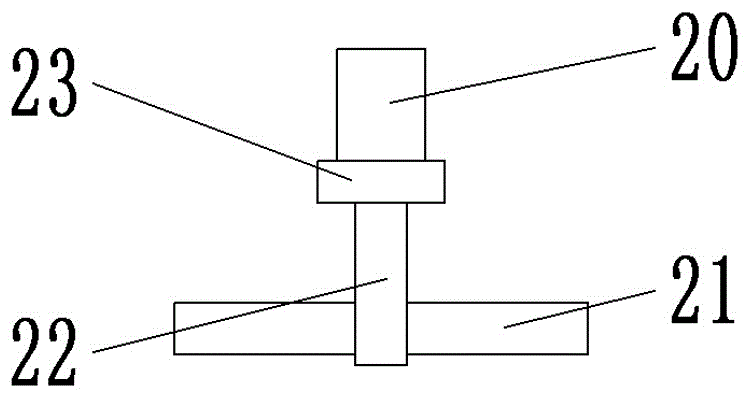

[0018] see Figure 1-5 , a chemical mixing tank that is easy to clean and can be pre-mixed, including a tank body 8 and an upper cover 2; the tank body 8 is set as a hollow cylinder, and the interior is divided into a pre-mixing chamber 3 and a stirring chamber 12 by a partition 13 ; The partition 13 is evenly distributed with some through holes; the top opening of the tank body 8 is provided with a loam cake 2; the loam cake 2 is provided with a feed device; the feed device is divided into a first feed device 1 and the second feeding device 4; the first feeding device 1 and the second feeding device 4 are arranged on the left and right sides of the upper cover 2, and the first feeding device 1 and the second feeding device 4 are all fed by Tube 16 and feeding tube 15 are composed; the feeding tube 16 is arranged horizontally, both ends are closed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com