A spiral vane diversion type phase separation device

A technology of spiral flow diversion and phase separation, which is applied in the direction of swirl devices and devices whose axial direction of swirl can be reversed, etc. It can solve the problems that light phase fluids cannot be merged and cannot make full use of the circumferentially distributed rotation generating units, etc. , to achieve the effect of light weight, good industrial application prospect and high separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

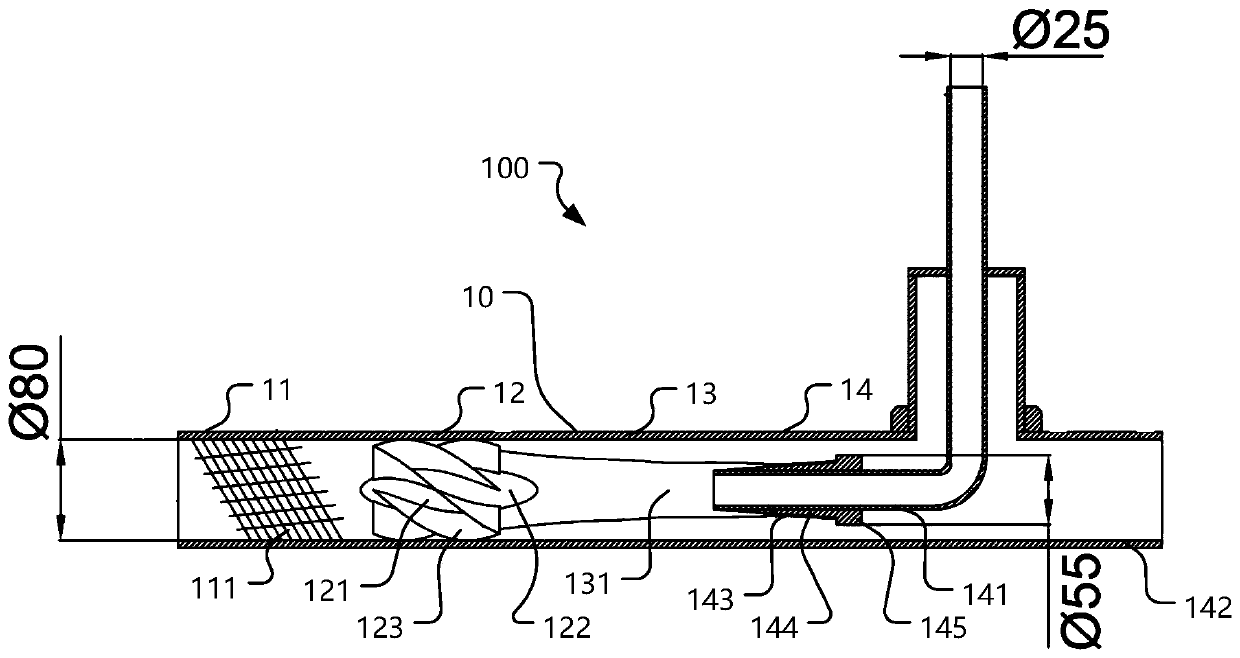

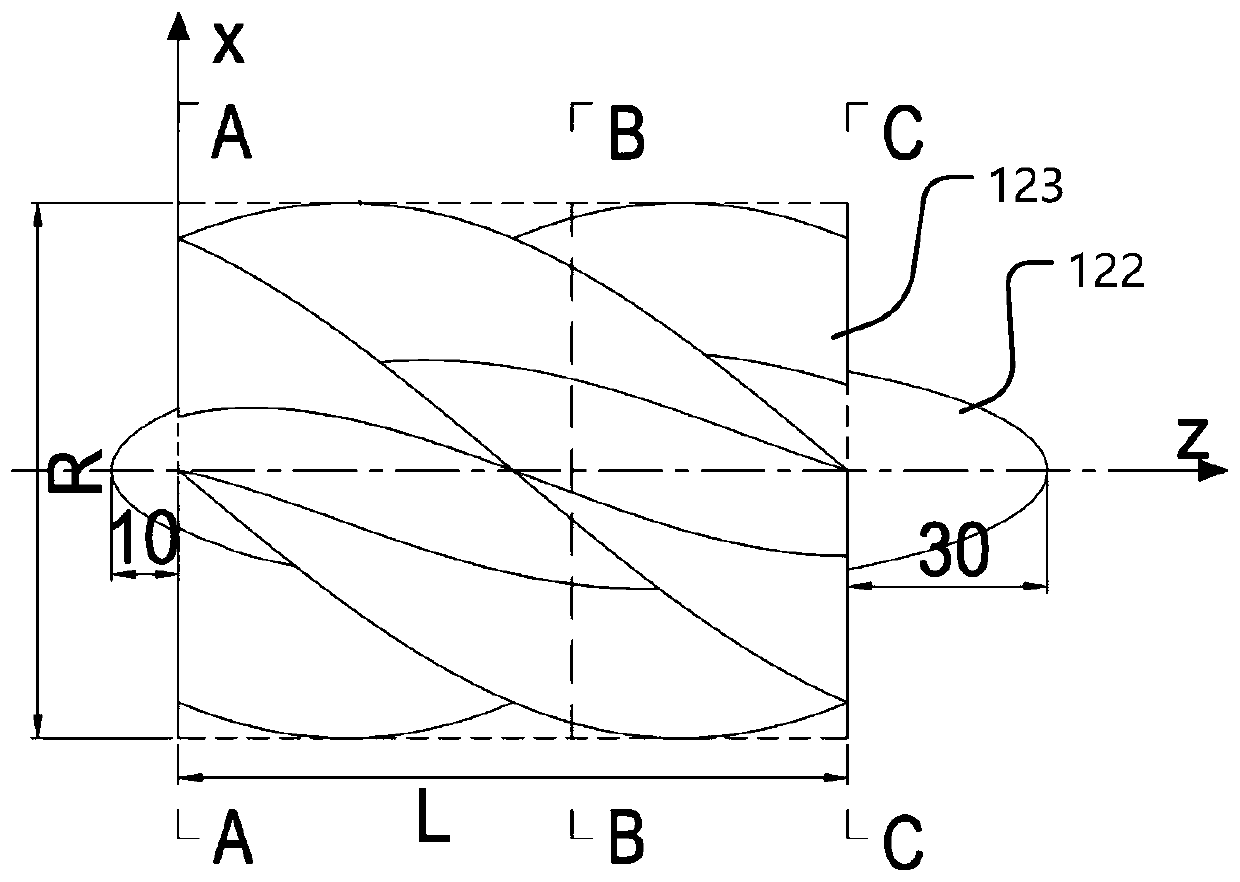

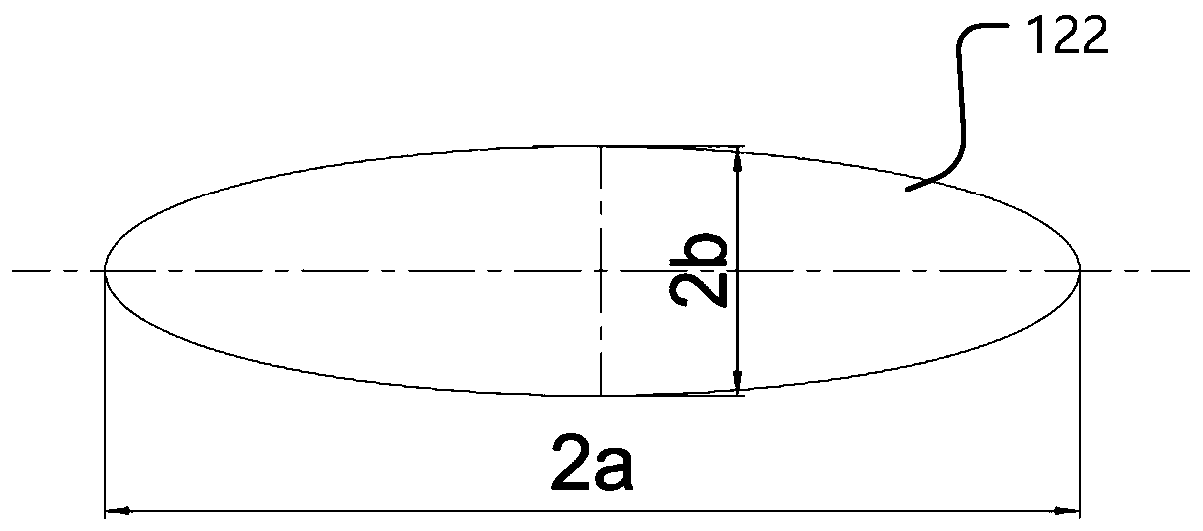

[0028] Such as figure 1 , 2 , 3, the spiral vane flow guide type phase separation device 100 of an embodiment of the present invention generally includes a separation pipe 10 for providing an installation basis for each component, and the separation pipe is based on the separation of the mixed liquid. The function is divided into mixing section 11, swirl section 12, separation section 13 and discharge section 14 in turn.

[0029] The blending section 11 is connected to the input pipe of the liquid to be separated, and a static mixer 111 is arranged inside, and the static mixer 111 is used to fully mix the input liquid, and the mixing includes multiple divisions, shifting and remixing, etc. The process makes the incoming mixed liquids that have already appeared stratification completely mixed together, providing guarantee for the subsequent cyclone separation. The static mixer 111 can make the incoming liquid mix regularly and repeatedly under the three mixing elements of "di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com