A bolt tightening device

A bolt and mounting plate technology, applied in the field of auto parts assembly, can solve the problems of safety accidents, labor cost, process, quality, efficiency, working hours not as good as automatic equipment, and labor consumption of workers, etc., to avoid safety accidents, use a wide range, The effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below with reference to the embodiments and accompanying drawings.

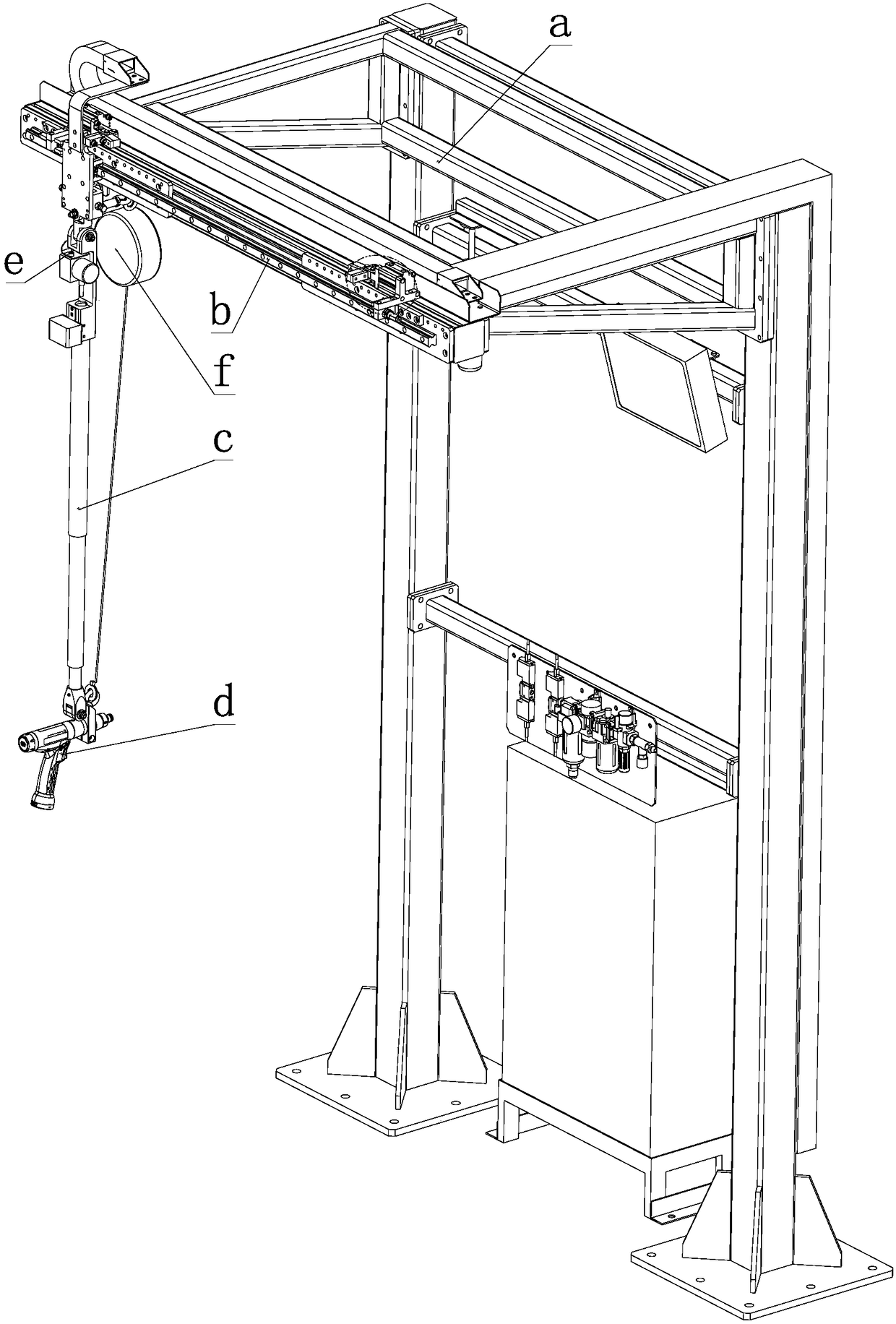

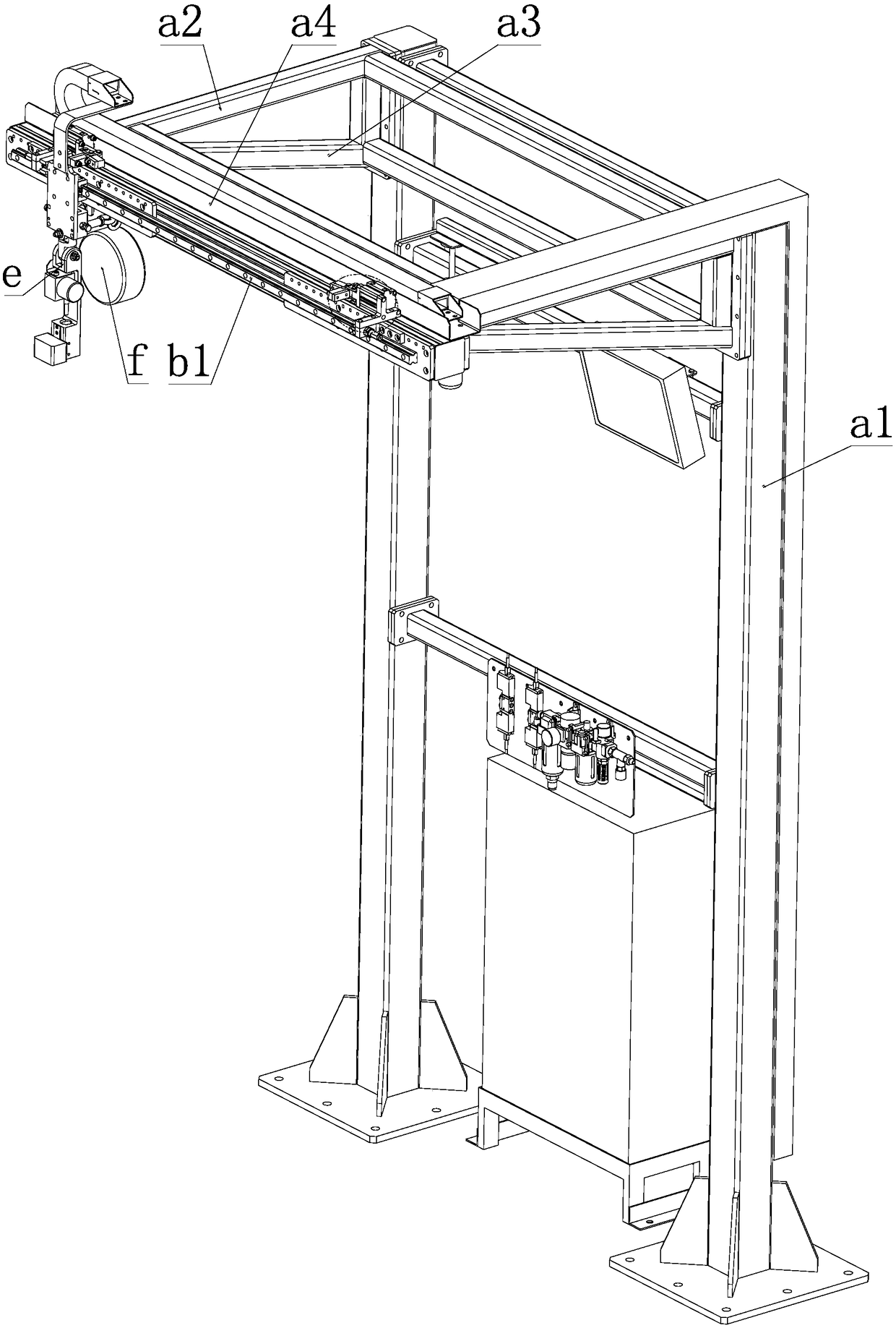

[0029] like figure 1 and figure 2 As shown, a bolt tightening device includes a bracket a, a horizontal linear sliding mechanism b is arranged on the bracket a, a lifting mechanism c is arranged on the horizontal linear sliding mechanism b, and an automatic wrench d is arranged on the lifting mechanism c, The lifting mechanism c is connected to the horizontal linear sliding mechanism b through a universal joint e.

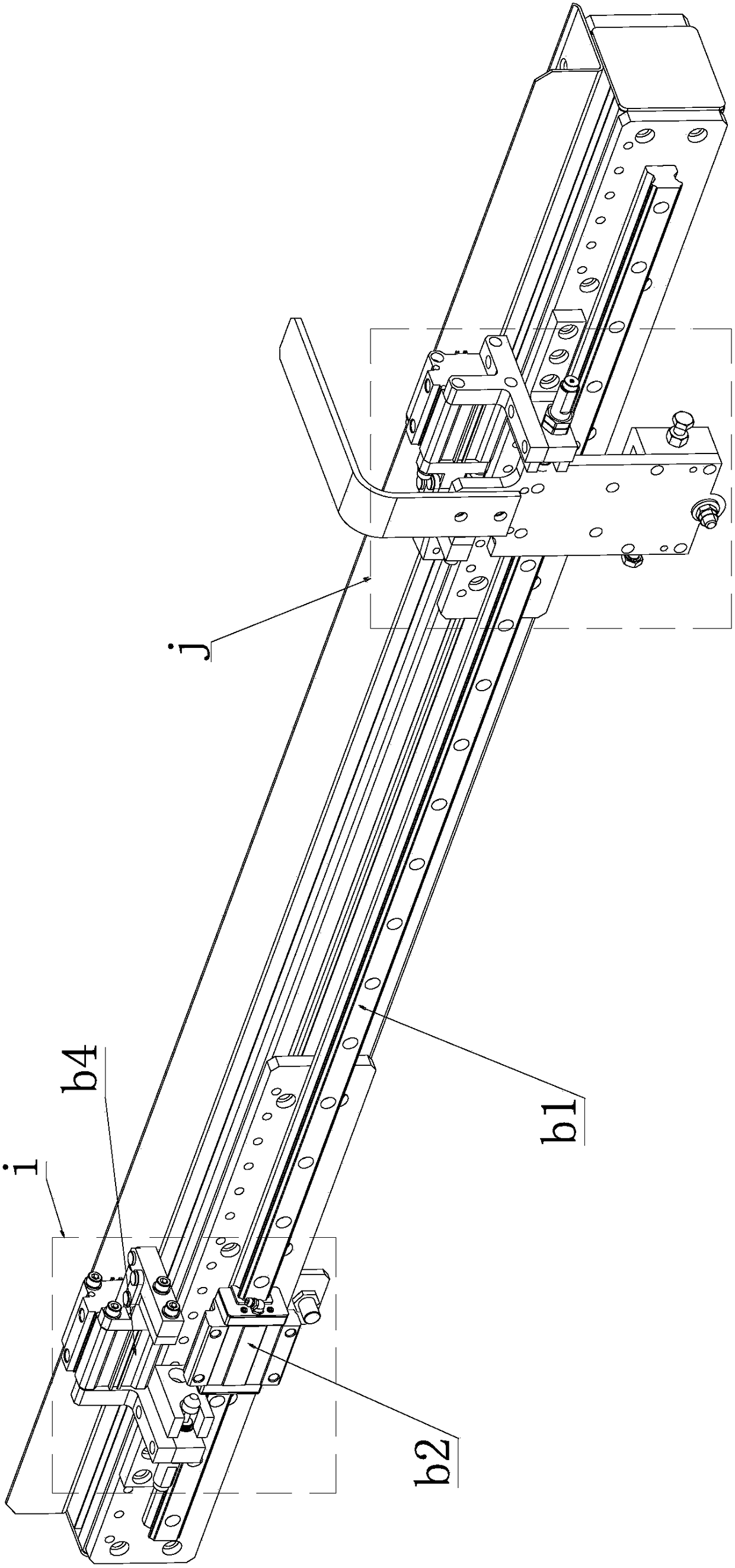

[0030] combine image 3 , Figure 4 and Figure 5 It can be seen that the horizontal linear sliding mechanism b includes a horizontal linear sliding rail b1 and a sliding block b2 that are slidably matched with each other, wherein the horizontal linear sliding rail b1 is installed on the bracket a, and a sliding block is provided on the bracket a The origin positioning device b4 has a plurality of sets of adjustment holes horizontally di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com