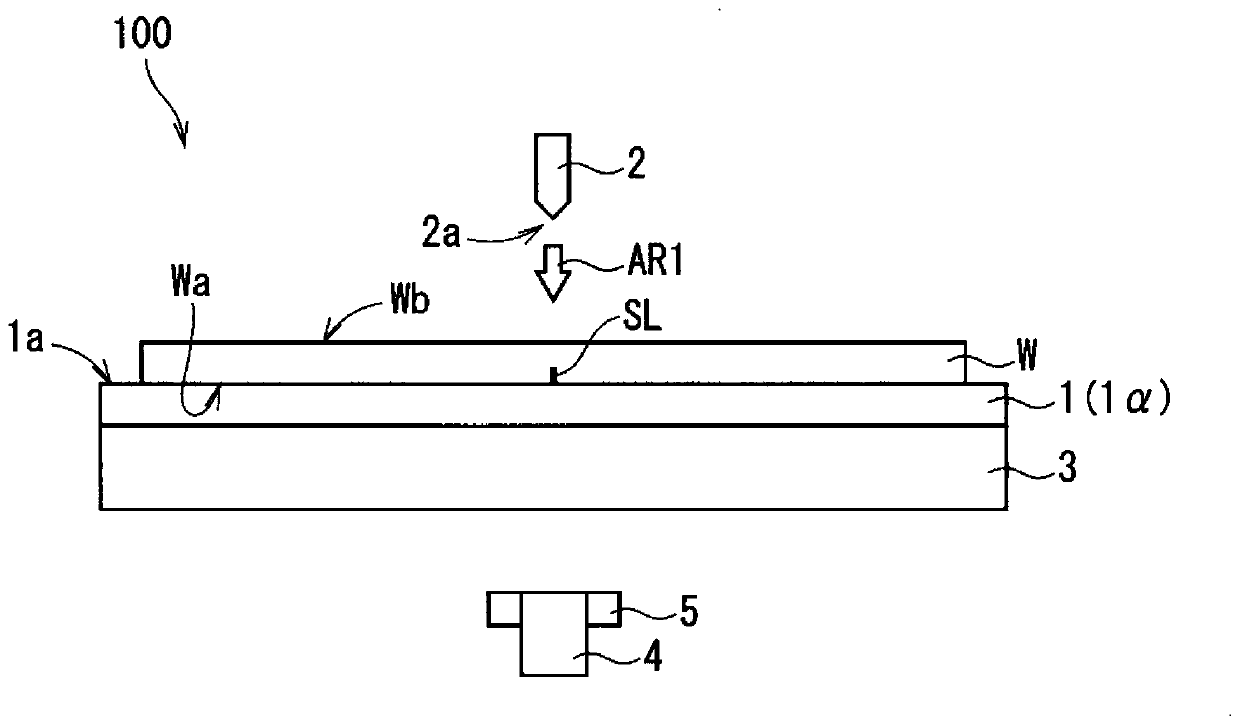

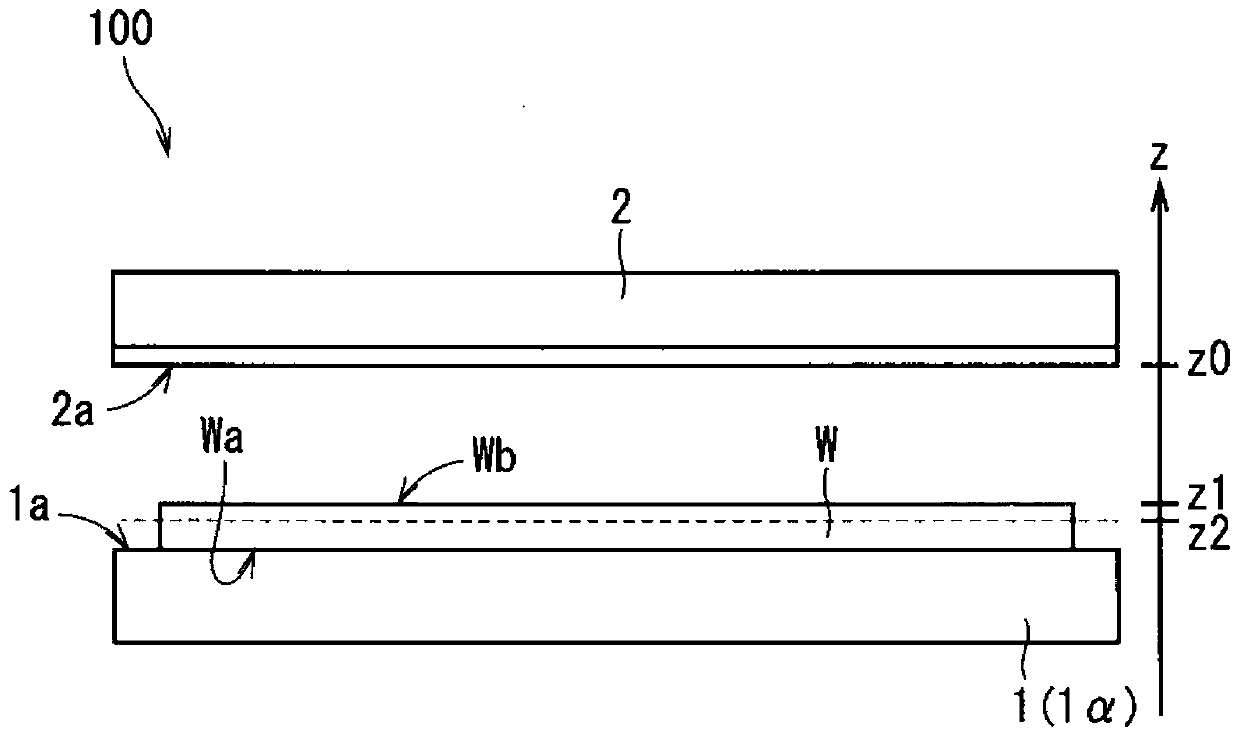

Cutting device, substrate cutting method, and member for substrate mounting portion of cutting device

A cutting device and mounting part technology, applied in glass cutting devices, fine work devices, work accessories, etc., can solve the problems of insufficient pressing, residual cracking, uneven cutting edges, etc., to ensure the effect of legibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0096] The polishing treatment was performed on the initial elastic body 11β, and the effectiveness of the polishing treatment was confirmed. Specifically, as the initial elastic body 11β, prepare two silicone rubbers with a planar size of 60mm×310mm, a thickness of 3mm (both design values) and a hardness of 80° (as sample 1-1, sample 1-2 ) were polished using a #80 porous grindstone in a state in which they were each fixed to the adsorption plate of the flat grinding disc. For each sample, the irregularity cross section was measured using the laser displacement meter using the adsorption surface before and after the buffing as a reference. The maximum unevenness difference (the difference between the maximum height position and the minimum height position) obtained from the obtained cross section is as follows. also, Figure 8 It is a figure which shows the uneven|corrugated cross-section before and after the buffing process about the sample 1-2. In addition, in Figure 8...

Embodiment 2

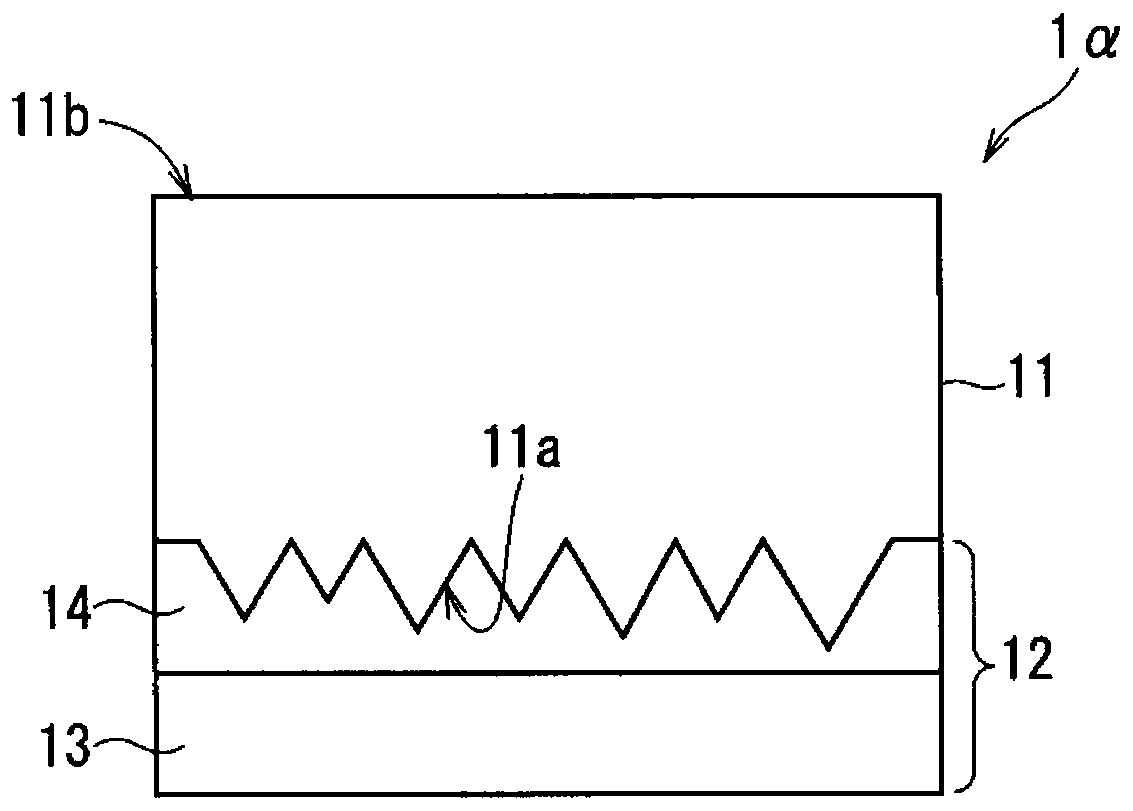

[0101] Various evaluations were performed on the mounting portion member 1α using a transparent elastic body as the elastic body 11 .

[0102] Specifically, four silicone rubbers having a hardness of 60°, which were polished in the same manner as in Example 1, and finally polished were prepared, and different films 12 (film types A to D) were attached to each of them, and 4 films were produced. Members 1α for each mounting portion (as samples 2-1 to 2-4). The type, base material thickness, and total thickness of the film 12 used in each sample are as follows.

[0103] Sample 2-1: film type A (Gelpoly (registered trademark) GPD38-A02A04 manufactured by Panac Co., Ltd.), 38 μm, 53 μm;

[0104] Sample 2-2: film type B (Panaprotect (registered trademark) PX50T01A15 manufactured by Panac Co., Ltd.), 50 μm, 65 μm;

[0105] Sample 2-3: film type C (Panaprotect (registered trademark) GS38 manufactured by Panac Co., Ltd.), 38 μm, 53 μm;

[0106] Sample 2-4: film type D (OTT50 (regis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com