Constant-temperature heat-storage belt fabric

A fabric and constant temperature technology, which is applied in the field of textile fabrics and fabrics, can solve problems such as difficult promotion and application, short service life, and poor belt quality, and achieve the effects of good product shape, improved stability, and increased absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

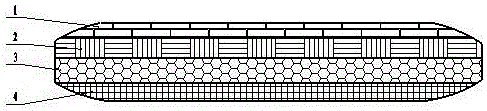

[0014] see figure 1 , a constant temperature heat storage belt fabric, including a skin layer, the inside of the skin layer is sequentially provided with a shaping layer, a filling layer and a skin layer; the skin layer is made of top layer calfskin; the shaping layer is made of ramie fiber Woven with a linear density of 1.02-1.31dtex, a warp density of 110-120 threads / 10cm, and a weft density of 100-105 threads / 10cm; the filling layer is filled with SEE ecological cotton; the outer skin layer is made of raw leather, Layers are secured with cotton yarn stitching all around.

[0015] A kind of production technology of belt fabric, comprises the steps:

[0016] Step 1: Cut the top layer of calfskin cowhide into a belt shape as the epidermis, and cut the regenerated leather into a belt shape as the outer skin layer;

[0017] Step 2: Cut the shaping layer made of ramie fiber and the filling layer filled with SEE ecological cotton according to the edge of the skin layer by 1mm; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com