High-strength heat insulating material for hydraulic concrete

A technology of hydraulic concrete and thermal insulation materials, which is applied in the field of concrete thermal insulation, can solve the problems of thermal insulation material promotion and application scope limitations, thermal insulation materials are easily damaged, and poor bonding ability, etc., and achieve low damage rate, cost saving, and bonding good performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

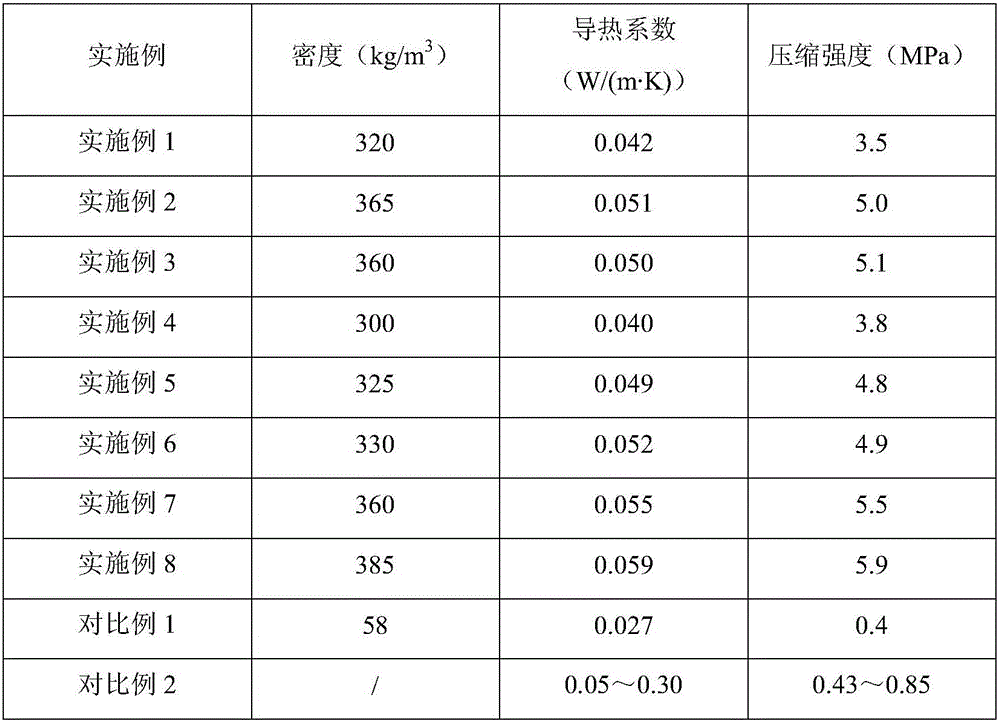

Examples

Embodiment 1

[0036] The hydraulic concrete high-strength thermal insulation material is prepared from the following raw materials and weight ratios:

[0037] Component A of gelling material: 19 parts;

[0038] A component is isophorone diisocyanate.

[0039] Component B of gelling material: 21 parts;

[0040] The foaming component in component B is distilled water, the catalyst is potassium isooctanoate, and polypropylene glycol:distilled water:potassium isooctanoate=30:1:1.

[0041] Modified fly ash floating beads: 40 parts;

[0042] Modified hollow glass microspheres: 15 parts.

Embodiment 2

[0044] The hydraulic concrete high-strength thermal insulation material is prepared from the following raw materials and weight ratios:

[0045]Component A of gelling material: 26 parts;

[0046] A component is dicyclohexylmethane diisocyanate.

[0047] Component B of gelling material: 24 parts;

[0048] The foaming component in component B is distilled water, the catalyst is potassium acetate, and polypropylene glycol:distilled water:potassium acetate=30:4:1.

[0049] Modified fly ash floating beads: 25 parts;

[0050] Modified hollow glass microspheres: 30 parts;

[0051] Whiskers: 5 servings.

Embodiment 3

[0053] The hydraulic concrete high-strength thermal insulation material is prepared from the following raw materials and weight ratios:

[0054] Component A of gelling material: 33 parts;

[0055] A component is dicyclohexylmethane diisocyanate.

[0056] Component B of gelling material: 27 parts;

[0057] The foaming component in component B is cyclopentane, the catalyst is potassium isooctanoate, and polypropylene glycol:cyclopentane:potassium isooctanoate=30:2:1.

[0058] Modified fly ash floating beads: 20 parts;

[0059] Modified hollow glass microspheres: 35 parts;

[0060] Whiskers: 5 servings.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com