A compact blast furnace feeding system capable of centralized weighing of raw materials and fuels

A feeding system and compact technology, applied in the field of compact blast furnace feeding system, can solve the problems of large floor area and high investment, and achieve the effects of saving land and investment, clear functional divisions, and large feeding capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

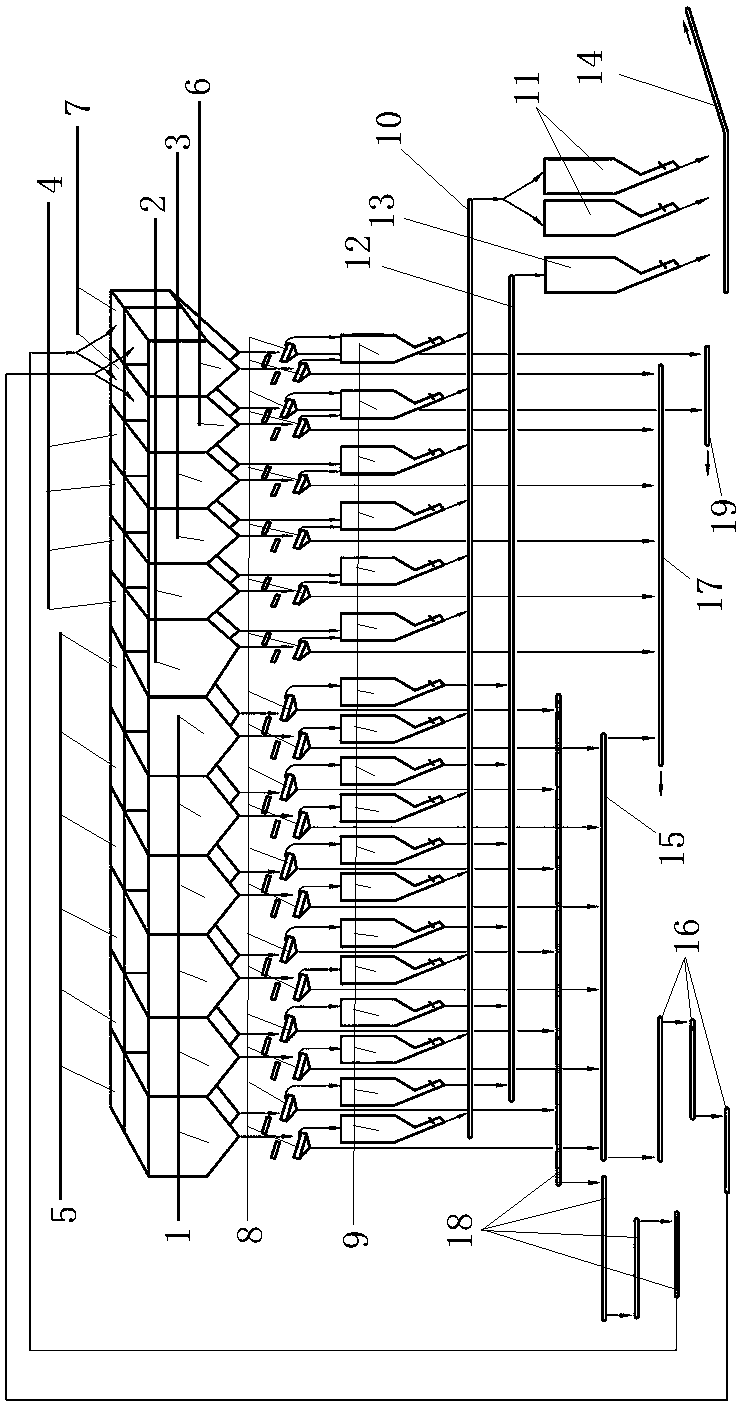

[0016] In order to better understand the present invention, below in conjunction with embodiment and accompanying drawing, technical scheme of the present invention is described further (as figure 1 shown).

[0017] A compact blast furnace feeding system that can centrally weigh raw materials and fuels, which includes ore coke trough, vibrating screen 8 under the trough, dispersive weighing bucket 9, ore supply belt conveyor 10, coke supply belt conveyor 12, reversible crushing and burning belt Machine 15, crushing and burning belt conveyor 16, ore returning belt conveyor 17, coke crushing belt conveyor 18, coke returning belt conveyor 19; , Miscellaneous ore tank 4, Coke tank 5, Broken sinter tank 6 and Coke broken tank 7 are arranged side by side (concentrated) in double rows (that is, they are arranged side by side in two rows up and down, the upper and lower rows of grooves are opposite to each other, and the upper and lower rows of grooves under each sinter trough 1, pel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com