A multi-element alloy co-infiltration furnace with full mixing and contact

A technology of co-infiltration and full mixing of multi-element alloys, which is applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc. The inner wall of the infiltration furnace is worn, the alloy co-infiltration treatment is uneven, etc., so as to avoid the weak position of anti-corrosion, reduce wear and deformation, and achieve good temperature resistance and wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

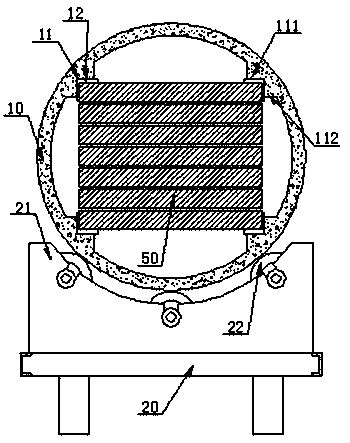

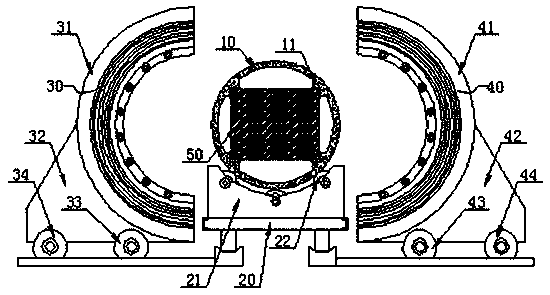

[0016] refer to Figure 1 to Figure 2 , Figure 1 to Figure 2 It is a structural schematic diagram of a specific embodiment of the present invention.

[0017] Such as figure 1 and figure 2 As shown, a multi-element alloy co-infiltration furnace with sufficient mixing and contact includes a rotating heating tank 10, a heating tank rotary car 20, a left heating furnace 30 and a right heating furnace 40, and the left heating furnace 30 and the right heating furnace The side heating furnaces 40 are combined to form a cylindrical heating chamber, the rotating heating tank 10 is arranged coaxially with the cylindrical heating chamber, and the rotating heating tank 10 is arranged on the heating tank rotating car 20 and can be arranged along the The axial movement of the rotary heating tank 10 can be rotated around the axial direction of the rotary heating tank 10; the inner wall of the rotary heating tank 10 is provided with vertical sections for clamping and fixing the bundled m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com