Method for manufacturing antibiotic warm keeping sized bamboo fiber cotton

A technology of bamboo fiber and shaped cotton, which is applied in the direction of non-woven fabrics, textiles, papermaking, adhesives, etc., can solve the problems of not easy to be scattered, easy to form a group, uneven thickness, etc., and achieve the effect of not easy to deform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment one (the shaped bamboo fiber cotton of producing 130g)

[0025] 1) batching: get 50% bamboo fiber, 15% low-melting point fiber, 15% polyester staple fiber, 20% 6D three-dimensional hollow fiber according to the best ratio of quality for batching, wherein the bamboo fiber is 51mm in length;

[0026] 2) Mixing: Feed the bamboo fiber, polyester staple fiber, and low-melting point fiber taken by mass ratio in the step 1) into the cotton blender, and stir for 5 minutes to form a mixed fiber;

[0027] 3) Opening and carding: the mixed fibers obtained in step 2) are sequentially opened and carded by an opener and a carding machine, and then sent into a web-laying machine;

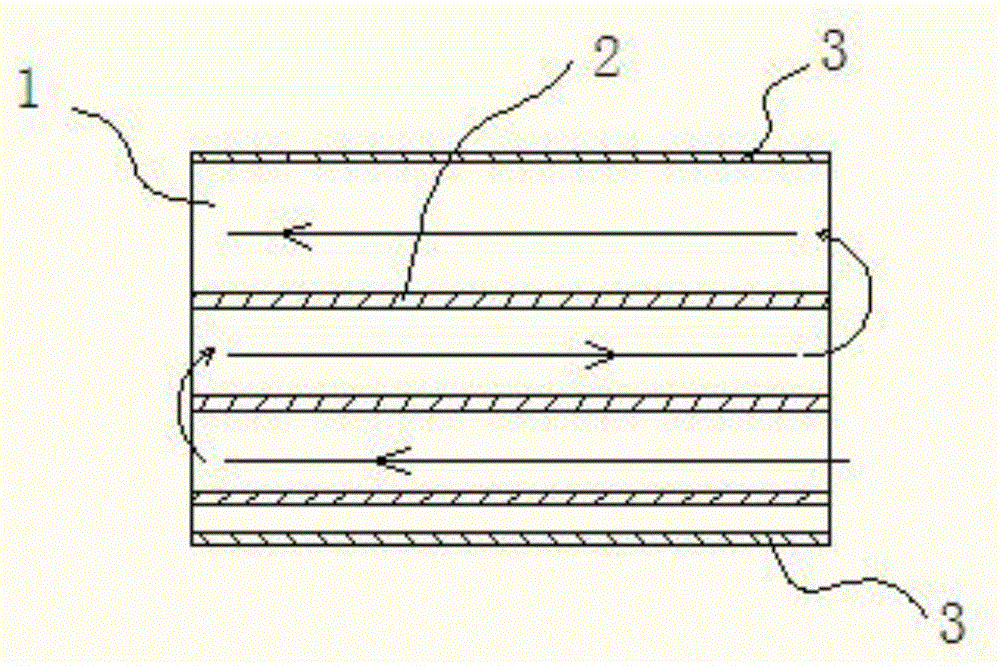

[0028] 4) Laying: Laying machine horizontally lays the mixed fiber after step 3) carding, and forms fetal cotton when it is output along the longitudinal direction; the number of laying layers is three layers.

[0029] 5) Baking: send the fetal cotton obtained in step 4) into an oven for heating...

Embodiment 2

[0032] Embodiment two (production the shaped bamboo fiber cotton of 260g)

[0033] 1) batching: get 55% bamboo fiber by mass ratio, 14% low melting point fiber, 14% polyester staple fiber, 17% 6D three-dimensional hollow fiber is carried out batching, and wherein bamboo fiber is 51mm length;

[0034] 2) Mixing: Feed the bamboo fiber, polyester staple fiber, and low-melting point fiber taken by mass ratio in the step 1) into the cotton blender, and stir for 5 minutes to form a mixed fiber;

[0035] 3) Opening and carding: the mixed fibers obtained in step 2) are sequentially opened and carded by an opener and a carding machine, and then sent into a web-laying machine;

[0036] 4) Laying: Laying machine horizontally lays the mixed fiber after step 3) carding, and forms tire cotton when it is output along the longitudinal direction, and the number of laying layers is 6 layers (the speed of laying is appropriately accelerated).

[0037] 5) Baking: send the fetal cotton obtained i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com