A drillable bolt device and construction method capable of realizing cross anchorage

A bolt and anchoring technology, which is applied to the installation of bolts, earthwork drilling, mining equipment, etc., can solve the problem of not being able to determine the anchoring position of the end of the bolt, increasing the safety hazards of construction workers, and failing to achieve the expected anchoring effect and other problems, to achieve the effect of simple and feasible installation procedure, improve the working conditions of workers, and reduce the anchorage length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

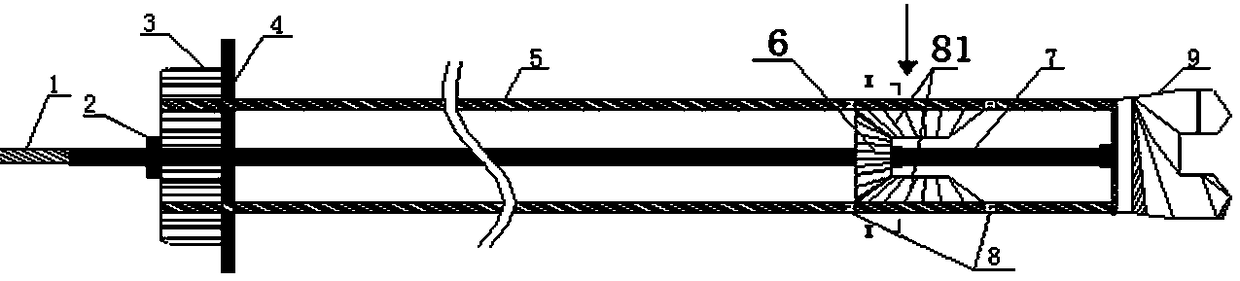

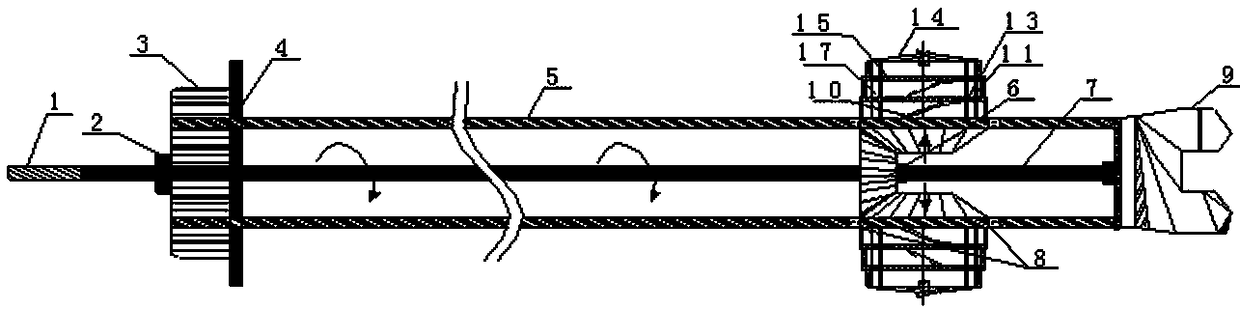

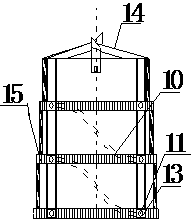

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0030] Such as Figure 1-2 As shown, it is a schematic diagram of the overall structure of the anchor rod device of the present invention. The anchor rod of the present invention is composed of a transmission rod 1, a fixed nut 2, a nut 3, a tray 4, a hollow anchor rod 5, a driving gear 6, a fixed rod 7, a bearing 8, an anchor Rod bit 9 and three telescoping bits. In the present invention, the external drilling rig transmits telescopic power to the inside of the bolt through the transmission rod 1 .

[0031] The tray 4 and the fixing nut 2 are provided with a circular hole to allow the transmission rod 1 to pass through and fix the position of the transmission rod 1 . The tray 4 is installed on the rear end of the hollow anchor rod 5 through the nut 3, so that the transmission rod 1 extends into the hollow anchor rod 5 and is connected with the driving gear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com