A fan power system

A technology for power systems and fans, applied in the directions of machines/engines, mechanical equipment, liquid fuel engines, etc., can solve the problems of limited functional capacity of the fan system, and achieve the effects of compact structure, large air volume, and enhanced aerodynamic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

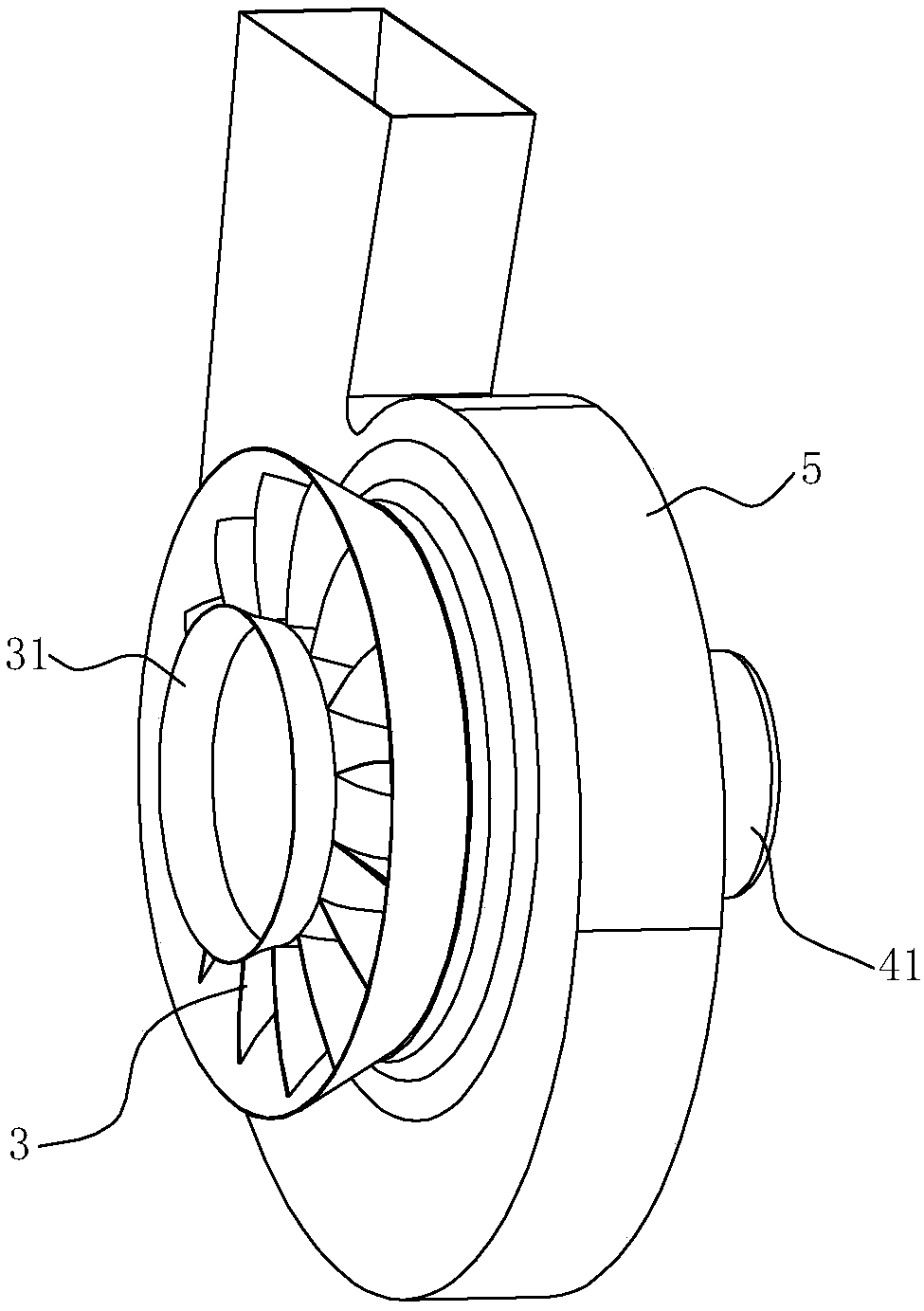

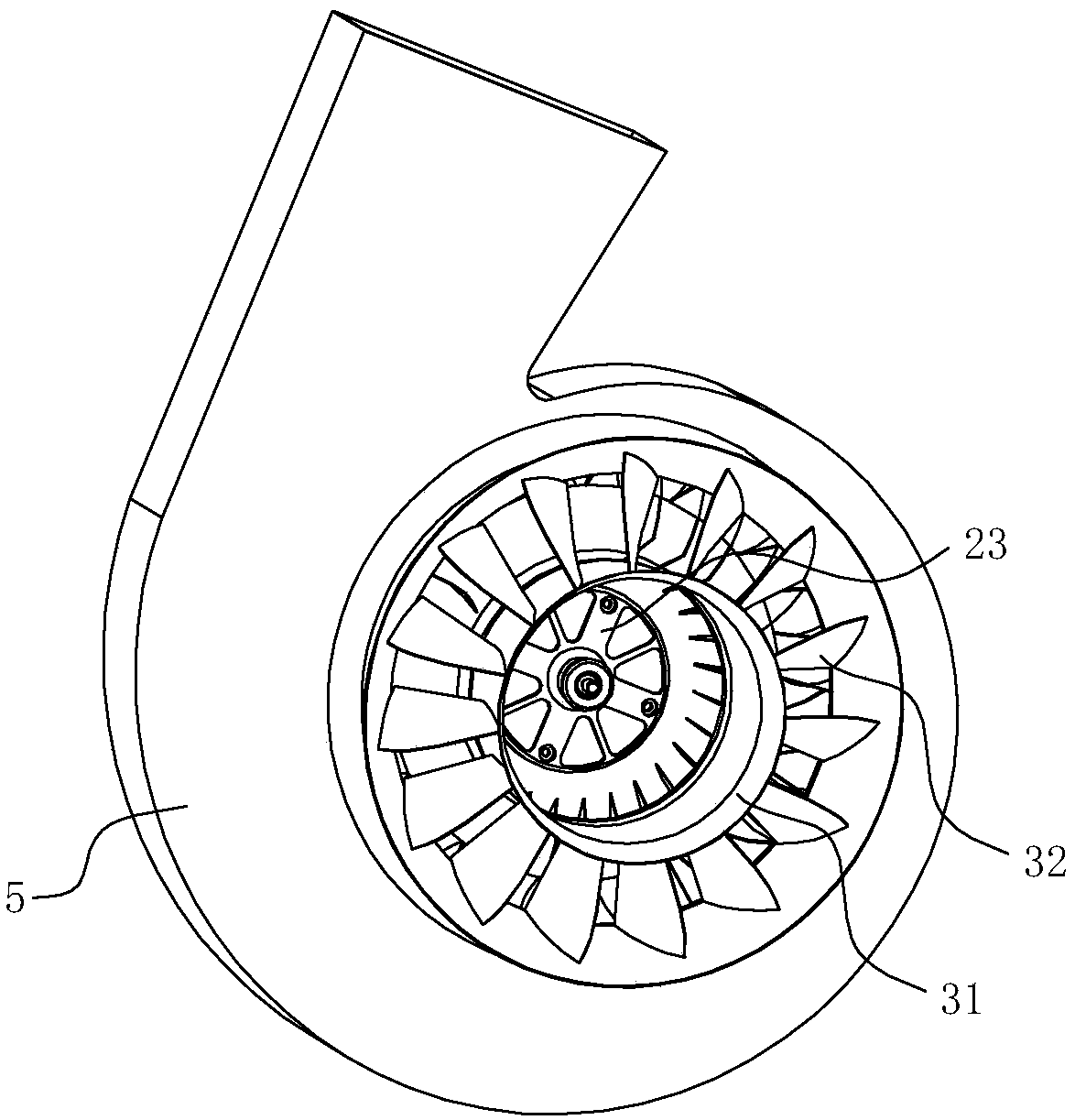

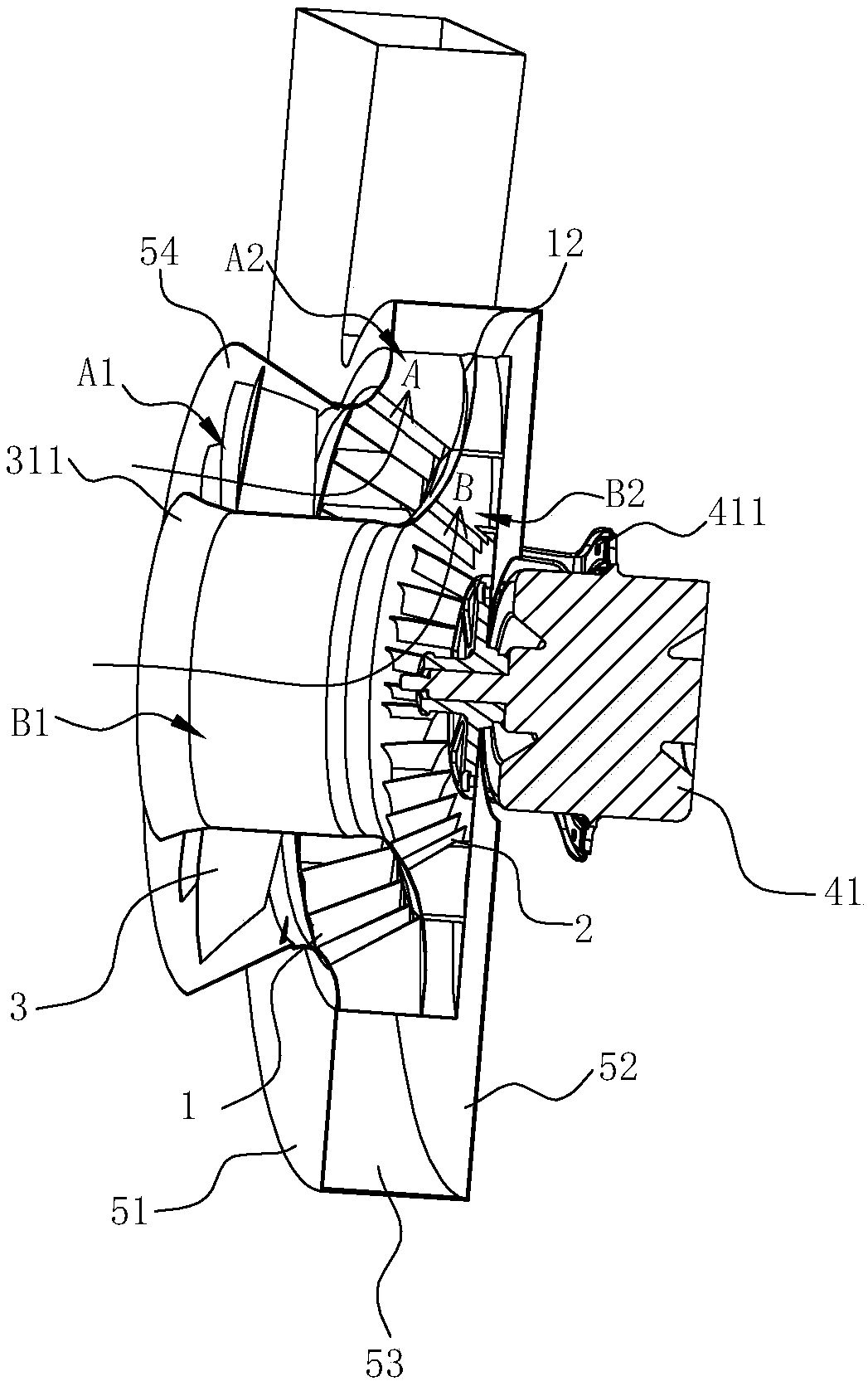

[0041] see Figure 1 ~ Figure 4 , a fan power system, including a centrifugal fan, an axial flow fan 3, a first motor 41 and a volute 5, the centrifugal fan includes a first centrifugal fan 1 and a second centrifugal fan 2 coaxially arranged side by side in front and rear, the shaft The flow fan 3 is connected in series on the front side of the first centrifugal fan 1, thus making the fan power system form two airflow channels: the main airflow channel, image 3 As indicated by the middle arrow A, and the auxiliary airflow channel, image 3 Indicated by the middle arrow B.

[0042]The above-mentioned first centrifugal fan 1 , second centrifugal fan 2 and axial flow fan 3 are driven by the same first motor 41 . The volute 5 includes a front cover 51, a rear cover 52, and an intermediate cover 53 between the front cover 51 and the rear cover 52. An air inlet 511 is formed on the front cover 51 of the volute 5, and the front cover On the front side of the plate 51 , at the pos...

Embodiment 2

[0052] see Figure 13 , in this embodiment, the difference from the first embodiment above is that in order to better match the main air flow channel A and the auxiliary air flow channel B, and further enhance the fan's ability to work on the air flow, the hub 31 is located behind the front end 311 The peripheral wall of the side part extends obliquely, so that the shape of the hub 31 is a cone whose outer diameter gradually increases from the front to the rear, thereby making the cross-sectional area of the main airflow channel A gradually decrease from the front to the rear, so that the airflow can be accelerated after entering , to maximize the working capacity of the front axial flow fan 3 .

Embodiment 3

[0054] see Figure 14 , in this embodiment, the difference from the first embodiment above is that in order to better match the main air flow channel A and the auxiliary air flow channel B, and further enhance the fan's ability to work on the air flow, the hub 31 is located behind the front end 311 The peripheral wall of the side portion extends in a curved shape, so that the shape of the hub 31 is a bionic curve shape in which the outer diameter gradually increases from the front to the rear, thereby making the cross-sectional area of the main airflow channel A gradually decrease from the front to the rear, so that the airflow enters the Finally, it can be accelerated to maximize the working ability of the front axial flow fan 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com