Circuit and method for controlling hydraulic valve flow

A technology for controlling circuits and hydraulic valves, applied in the direction of valve operation/release devices, valve details, valve devices, etc., can solve problems such as unsuitable for general design, single control object, easy to be cracked, etc., and achieve control parameter confidentiality Strong, real-time monitoring parameters, stable static characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

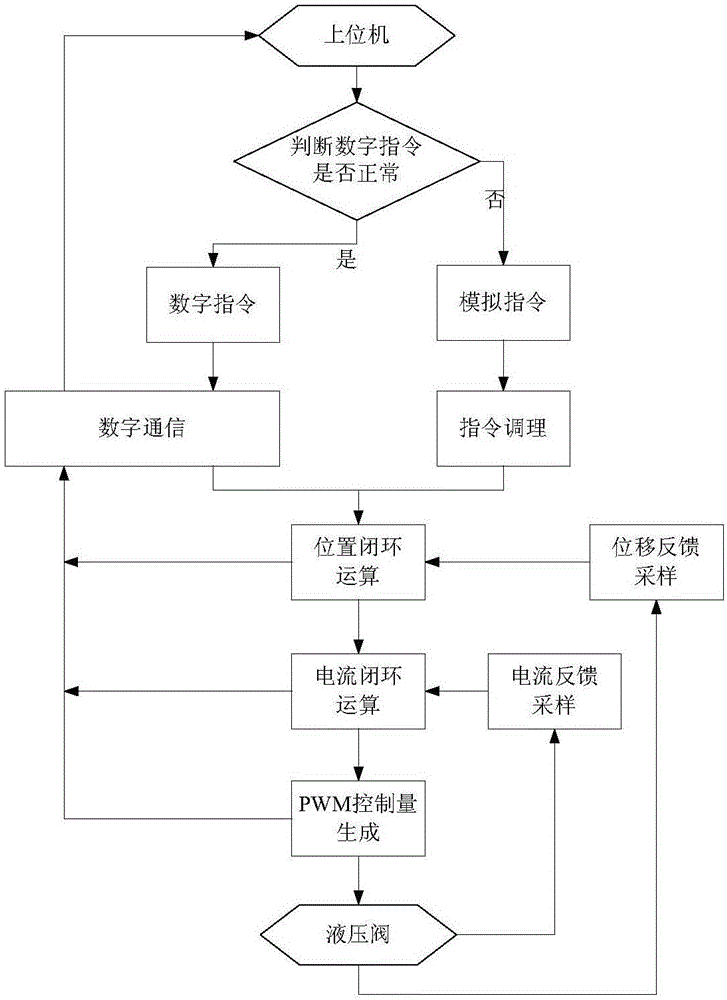

[0055] The present invention will be described in further detail below with reference to the accompanying drawings.

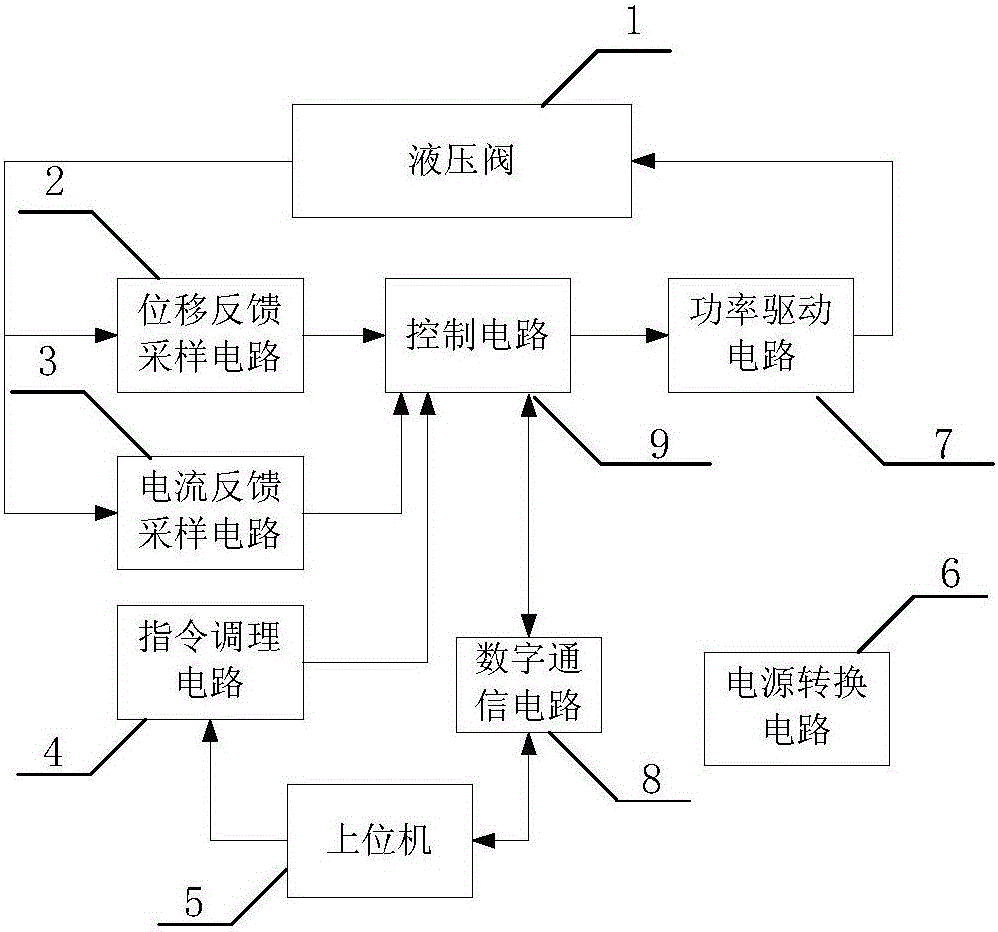

[0056] like figure 1 As shown in the figure, a circuit for controlling the flow rate of a hydraulic valve includes a hydraulic valve 1, a displacement feedback sampling circuit 2, a current feedback sampling circuit 3, an instruction conditioning circuit 4, a host computer 5, a power conversion circuit 6, a power drive circuit 7, and digital communication. circuit 8, control circuit 9;

[0057] Hydraulic valve 1 transmits its spool displacement signal and valve coil current signal to displacement feedback sampling circuit 2 and current feedback sampling circuit 3 respectively; displacement feedback sampling circuit 2 receives the spool displacement signal transmitted by hydraulic valve 1 and processes it into control circuit 9 The voltage signal can be received, and the voltage signal is transmitted to the control circuit 9; the current feedback sampling circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com