Tension force tester of aviation tire supporting framework

A technology for aviation tires and testing machines, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., to achieve high testing accuracy, shortening manual adjustment time, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below in conjunction with the accompanying drawings: the present embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation is provided, but the protection scope of the present invention is not limited to the following embodiments.

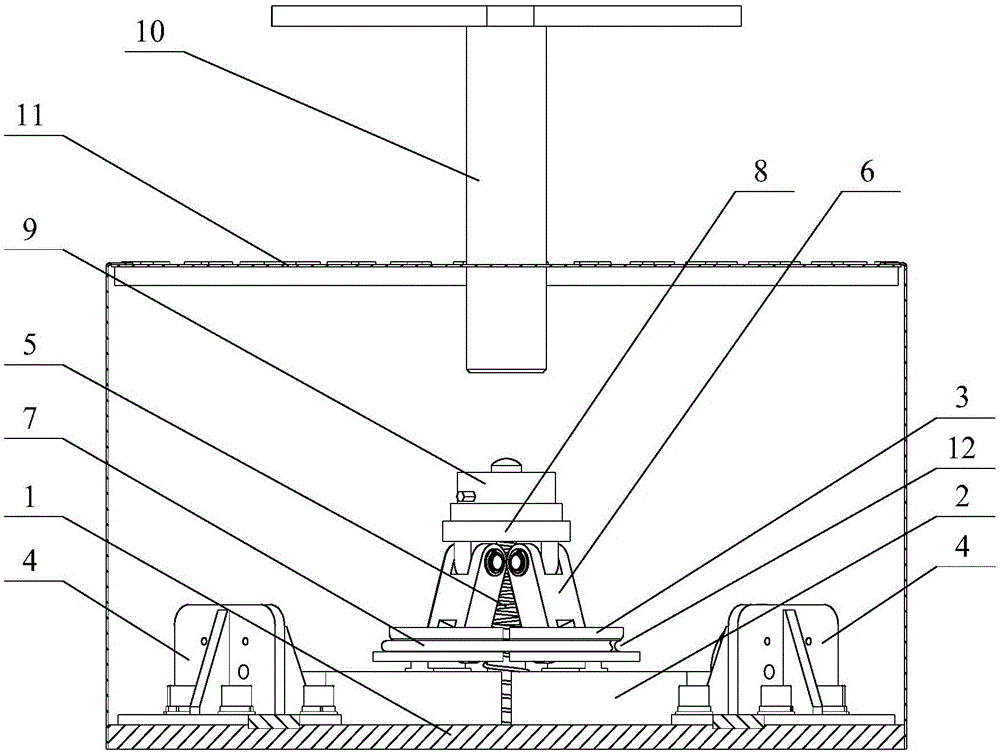

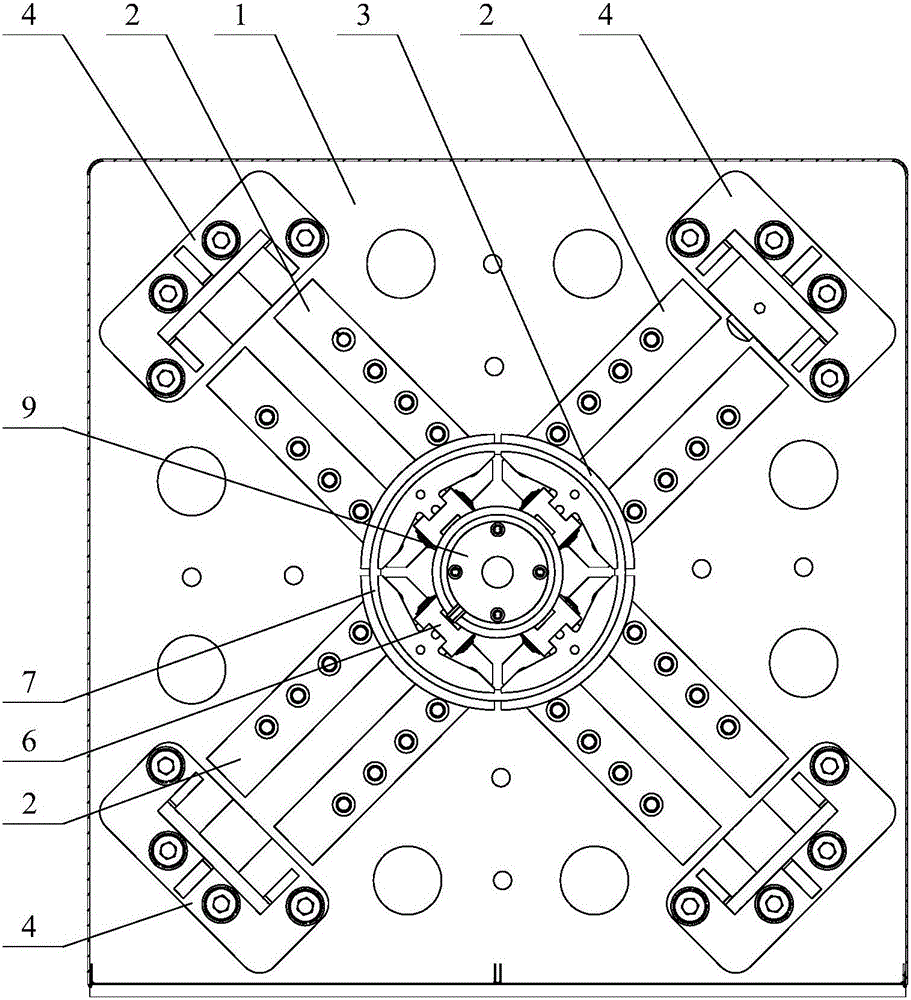

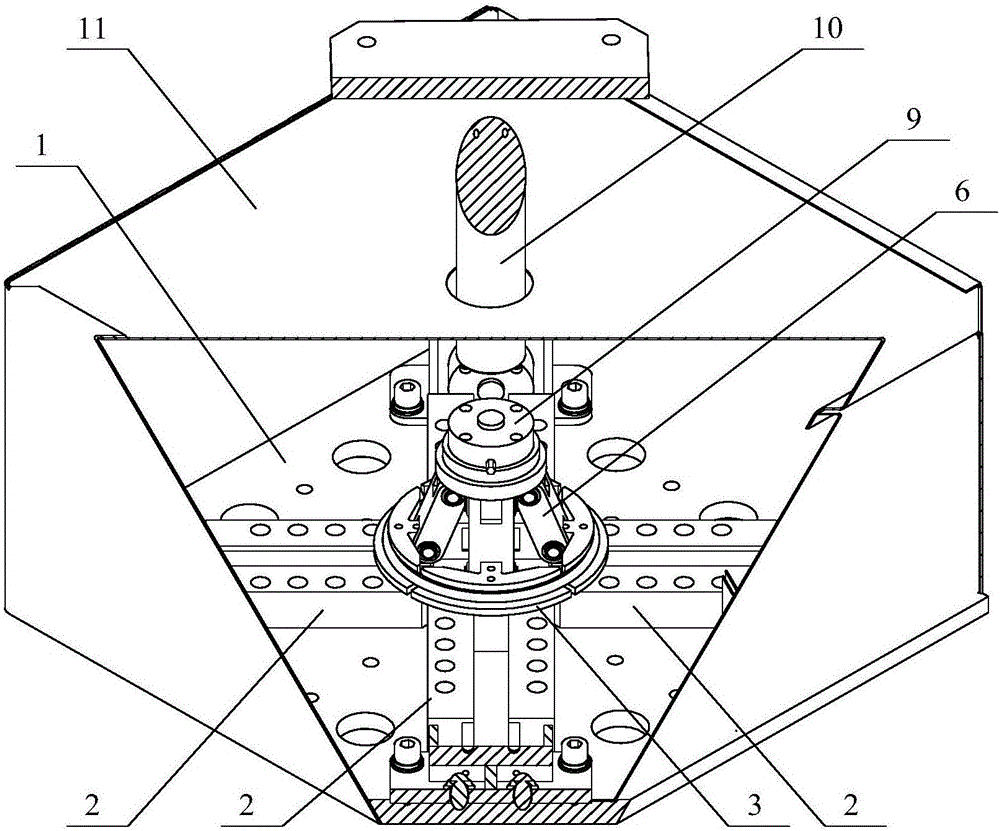

[0012] Such as Figure 1 ~ Figure 3 As shown, a kind of aircraft tire bearing frame tension testing machine involved in this embodiment includes: a base plate 1, four sets of slideways 2, four tension sliders 3, four limit plates 4, return springs 5, four A tension support arm 6, a compression tension disc 8, a pressure sensor 9 and a push rod 10, the four sets of slideways 2 are fixed on the bottom plate 1 in a cross shape, and a limiter is fixed on the bottom plate 1 at the outer end of each set of slideways 2. Position plate 4, a tension slider 3 is placed on each group of slideways 2, the lower end of the tension arm 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com