Flow distribution apparatus and fuel cell system

A current distribution and electric stack technology, which is applied in the direction of fuel cells, circuits, electrical components, etc., can solve the problem of uneven current distribution of the electric stack body, achieve uniform current distribution, ensure charge and discharge performance, and prolong life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

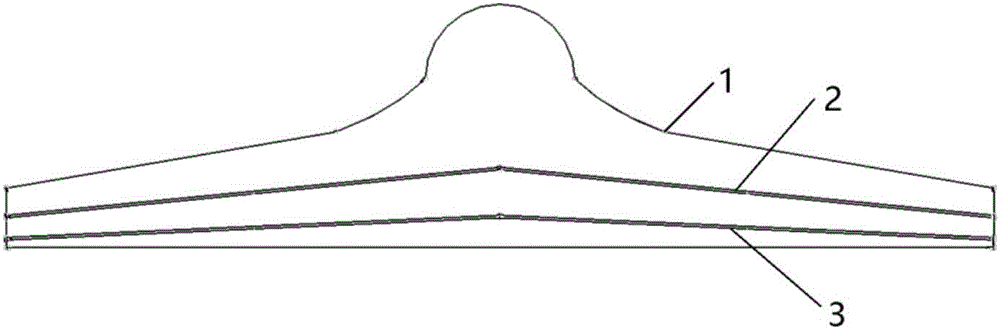

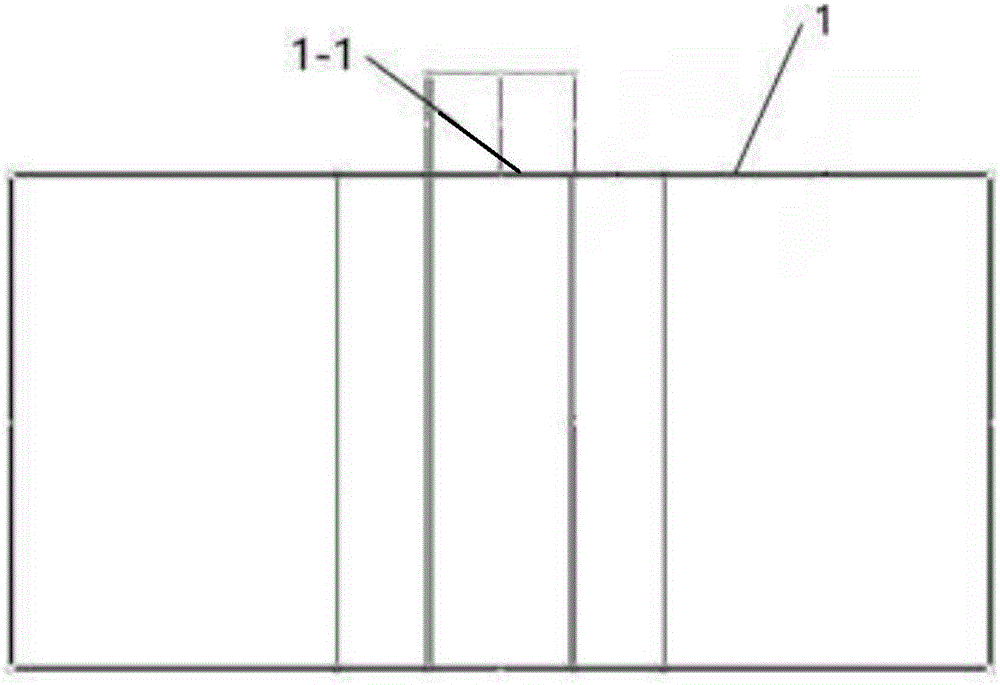

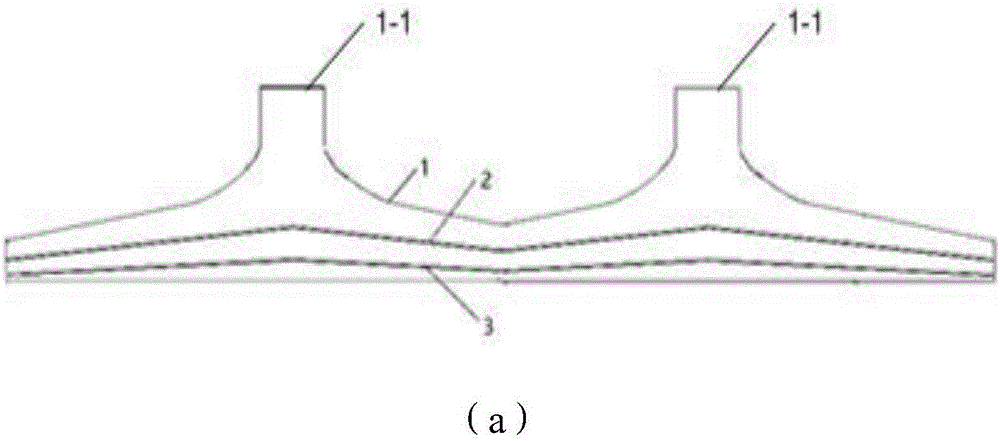

[0028] combine Figure 1 to Figure 3 As shown, the present invention provides a flow distribution device, which includes a top cover 1 and a first baffle plate 2, the top cover 1 has an opening and at least one concave cavity, and the top cover 1 includes a top plate and a shroud around the top plate The first baffle 2 is provided with a plurality of first flow parts 2-1 for the passage of gas, the first baffle 2 is covered at the opening of the top cover 1, and the first baffle 2 is provided with a concave The first bulge corresponding to the cavity, and the first bulge bulges toward the side where the top cover 1 is located, and the top cover 1 is provided with an air inlet 1-1 corresponding to the first bulge, that is, the air inlet 1-1 It can be located on the top plate of the top cover 1 and directly above the first raised portion, or on the enclosure plate of the top cover 1 and directly above the first raised portion. In addition, when the air inlet 1-1 is located on t...

Embodiment 2

[0038] The present invention also provides a fuel cell system, which includes a stack body and the above-mentioned flow distribution device, the intake side cover of the stack body is arranged at the opening of the top cover, and the stack body includes a plurality of bipolar plates, and at least one first through-flow portion is correspondingly provided above each bipolar plate.

[0039] The structure and principle of the flow distribution device in this embodiment are the same as those in Embodiment 1, and will not be repeated in this embodiment. In this embodiment, by setting a flow distribution device, it is ensured that the cathode of each bipolar plate is distributed with air, which promotes the chemical reaction of protons and electrons at the cathode, thereby improving the charging and discharging efficiency of the bipolar plate.

[0040] Further, it also includes the above-mentioned flow distribution device, the exhaust side cover of the stack body is arranged at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com