High-speed lossless ultrahigh-definition industrial visual detection method and system

A visual inspection and ultra-high-definition technology, which is applied in high-definition television systems, television systems adapted to optical transmission, and measurement devices, can solve the problems of large consumption of computing resources, achieve real-time performance, ensure transmission reliability, and avoid The effect of information loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

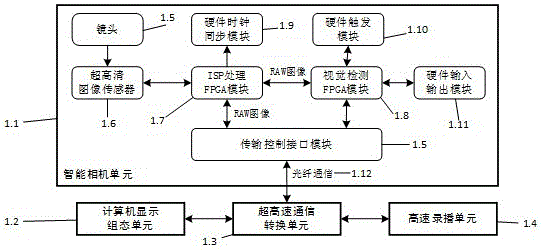

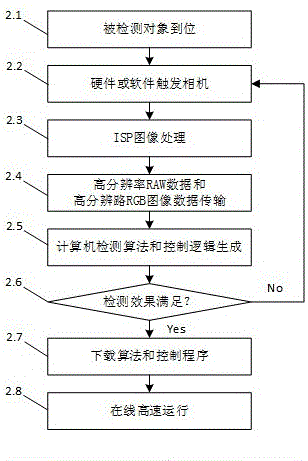

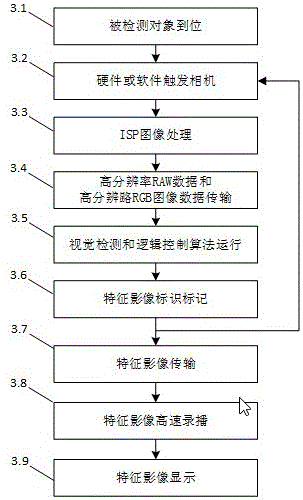

[0025] A high-speed non-destructive ultra-high-definition industrial vision inspection method and system, such as figure 1 As shown, including smart camera unit (1.1), ultra-high-speed communication conversion unit (1.3), computer display configuration unit (1.2), high-speed recording and broadcasting unit (1.4). The smart camera unit (1.1) collects ultra-high-definition image data of the detected object, performs visual inspection processing operations and logical control operations in two ways: high-resolution RAW data and RGB image data, and at the same time performs the processing and identification The feature image is transmitted to the high-speed recording and broadcasting unit (1.4) through the ultra-high-speed communication conversion unit (1.3) for recording and buffering. The computer display and configuration unit (1.2) performs asynchronous reading from the ultra-high-speed communication conversion unit (1.3) through the standard communication interface. Take and di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com