Malus hupehensis leaf black tea and production technology and production device thereof

A production process and production device technology are applied in the field of Begonia leaf black tea and its production process and production device to achieve the effects of reducing production cost, strong smell and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Embodiment 1 A kind of production technology of crabapple leaf black tea, concrete steps are as follows:

[0054] (1) Cleaning: Take the young leaves of Hubei crabapple that have grown for 20-50 days, and wash them with clean water;

[0055] (2) Withering of fresh leaves: the young leaves are spread out, and naturally adjusted to a water content of 45-50%;

[0056] (3) Leaf cutting: use a slicer to cut the tender leaves after conditioning into leaves with a length of 15-20mm;

[0057] (4) Kneading: The kneading time of 10kg leaves is 10-13min, if the kneading time is too long or too short, it will affect the quality of tea;

[0058] (4) Fermentation: Fermentation is carried out in a fermentation room of 80 square meters, the fermentation temperature is 40°C, the relative humidity is above 95%, the fermentation time is 10 hours, and the air volume is 8.5L / min. The content is between 60-65%;

[0059] (5) Initial drying: The fermented semi-finished product is initially ...

Embodiment 2

[0061] Example 2 The production device of crabapple leaf black tea

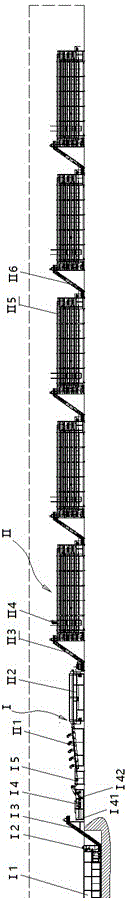

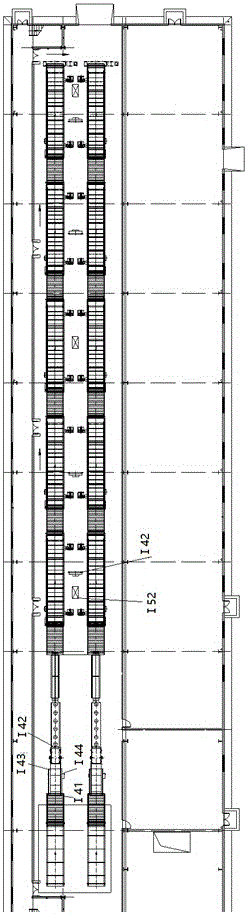

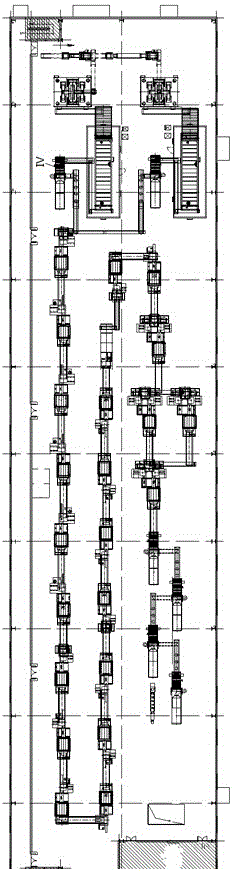

[0062] Such as Figure 1-10 As shown, the front end of the production device inputs the picked fresh leaves, and the processed crabapple leaf black tea is output from the rear end, in order to reduce costs and save production time. The production device includes cleaning part I, dehydration and withering part II, leaf cutting Fermentation part III, primary drying part IV, shaping loose bales part V and drying air selection part VI, each part or different structures of the same part are connected by conveyors or elevators, from the placement into the cleaning part After a series of processing, the young leaves (such as Hubei crabapple) used in the substitute tea in Ⅰ are processed substitute tea that is output from the drying and winnowing part VI.

[0063] The cleaning part includes green storage machine Ⅰ1, uniform leaf mechanism Ⅰ2, conveyor Ⅰ3, cleaning machine Ⅰ4, vibration drainer Ⅰ5. The young leaves ...

Embodiment 3

[0075]Example 3 A tea bag containing crabapple leaf black tea

[0076] It consists of the following components in parts by weight: 12 parts of crabapple leaf black tea, 3 parts of honeysuckle, 2 parts of celery leaf, 2 parts of cassia seed and 0.8 part of aloe.

[0077] Above-mentioned tea bag preparation method is as follows:

[0078] (1) Put each component in a container, add water until the components are completely submerged, and heat and extract 3 times, the heating temperature is 55-60°C, and the heating time is 40-50min;

[0079] (2) Mix the extracts obtained from the three extractions in step (1), concentrate under reduced pressure to a dry extract, and crush the extract through a 100-mesh sieve to obtain tea powder;

[0080] (3) Divide the tea powder into small bags for packaging.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com