Fine cigarette cut tobacco length controlling and sliver rejecting device and method for processing cut tobaccos

A technology of shredded tobacco length and rejecting device, which is applied in tobacco, tobacco processing, application, etc., can solve the problems of large energy consumption, large economic loss, and inability to recycle, etc., and achieves the effect of low energy consumption and small space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

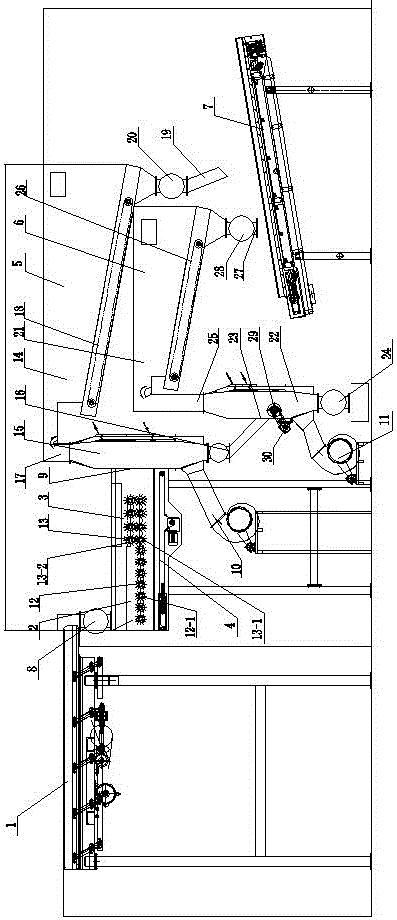

[0020] Such as figure 1 As shown, this invention discloses a device for controlling the length of shredded tobacco of thin cigarettes and removing stems, which includes a homogenizing vibrating conveyor 1, a sorting and breaking up area 2, a roller shearing area 3, a feeding belt conveyor 4, a second A multifunctional winnowing box 5, a second multifunctional winnowing box 6, and a discharge lifting conveyor 7; the sorting and breaking up area 2 and the roller shearing area 3 are respectively arranged above the inside of the feeding belt conveyor 4 in sequence, The material vibrating conveyor 1 is arranged in front of the feed end of the feed belt conveyor 4, the feed belt conveyor 4 is a sealed structure, and the feed end of the feed belt conveyor 4 is provided with a feed air lock 8, and the material The outlet end of the vibrating conveyor 1 is correspondingly arranged above the feed air lock 8 at the inlet end of the feed belt conveyor 4, and the first multifunctional winn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com