All-round package, environmental shoes and production process same

An all-round, wrapping technology, which is applied in the direction of footwear, soles, insoles, etc., can solve the problems of unsatisfactory environmental protection of shoes and the difficulty of wrapping to a good state, so as to simplify the manufacturing process of shoe uppers, omit the bottoming process, and improve processing efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

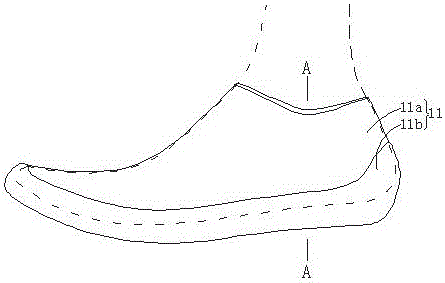

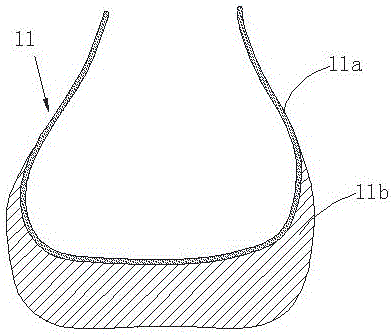

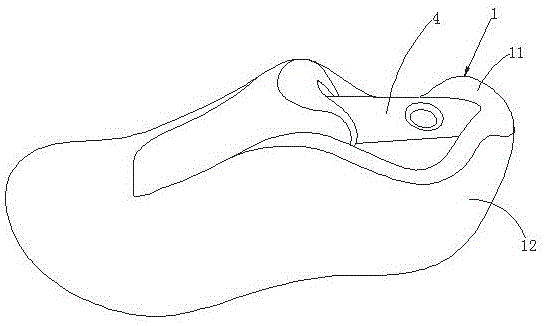

[0028] refer to Figure 4 The all-round wrapping and environment-friendly shoes include a shoe upper 1 and a shoe sole 2 , the shoe upper 1 is composed of an inner boot 11 and an upper 12 . refer to figure 1 , figure 2 , The inner boot 11 is composed of an inner lining 11a and an injection molding inner pad 11b. The inner pad 11b is a PU inner pad 11b made of PU material, or a popcorn inner pad 11b made by mixing PU and TPU popcorn particles, and the thickness of the inner pad 11b is 10-20mm. The inner lining 11a is a sock-shaped sock structure, or the inner lining 11a is a structure in which the neckline and bottom of the inner lining of the ordinary shoe upper 1 are open; the inner lining 11a is made of waterproof and / or breathable fabric. The inner lining 11a and the inner pad 11b are connected as one by injection molding. refer to image 3 , ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com