Expiratory valve used for respiratory protection device

A protective device and exhalation valve technology, applied in the field of exhalation valve, can solve the problems of increased inspiratory resistance, crowd influence, high material and production costs, etc., and achieve the effects of reduced exhalation resistance, smooth appearance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

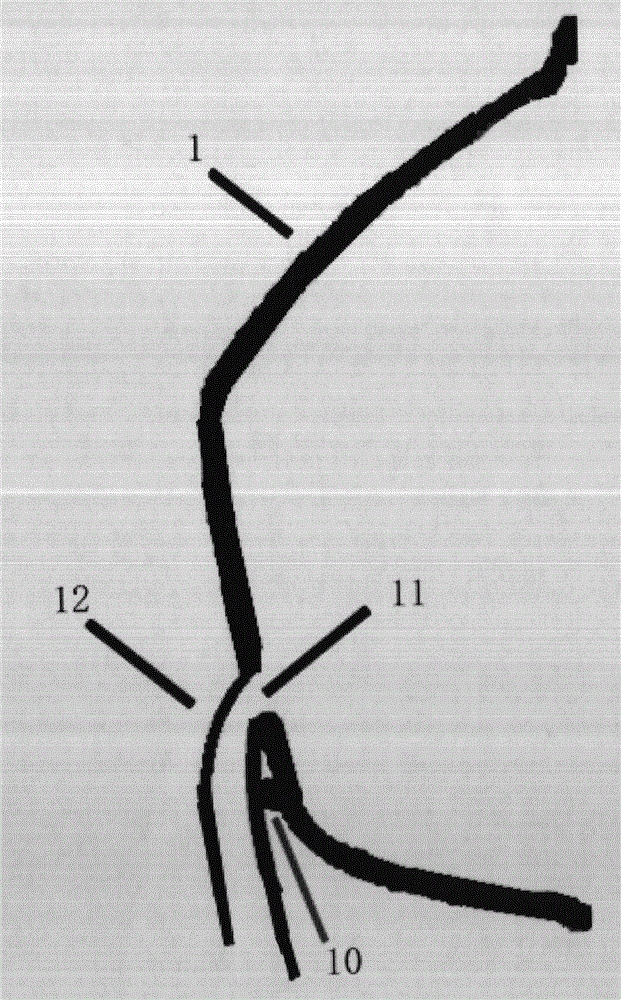

[0024] figure 1 It is a schematic diagram of the exhalation valve in Example 1 of the present invention when exhaling.

[0025] like figure 1 As shown, a through hole 11 is opened on the cover body 1, and one end of the exhaust pipe 12 is inserted into the through hole 11, and the wall of the end of the exhaust pipe 12 inserted into the end is airtightly fixed together with the edge of the through hole 11, The rest of the exhaust pipe 12 is placed outside the cover body 1 , and part of the pipe wall of the exhaust pipe 12 is fixed on the outside of the cover body 1 through bonding points 10 .

[0026] In this embodiment 1, the through hole 11 is circular, but it is not limited thereto. The size and shape of the through hole 11 are not limited; The middle part of body 1, near the mouth and nose.

[0027] Exhaust pipe 12 is a flexible pipe, and it is made of frivolous, soft, air-tight film material, such as plastics, rubber or composite material etc.

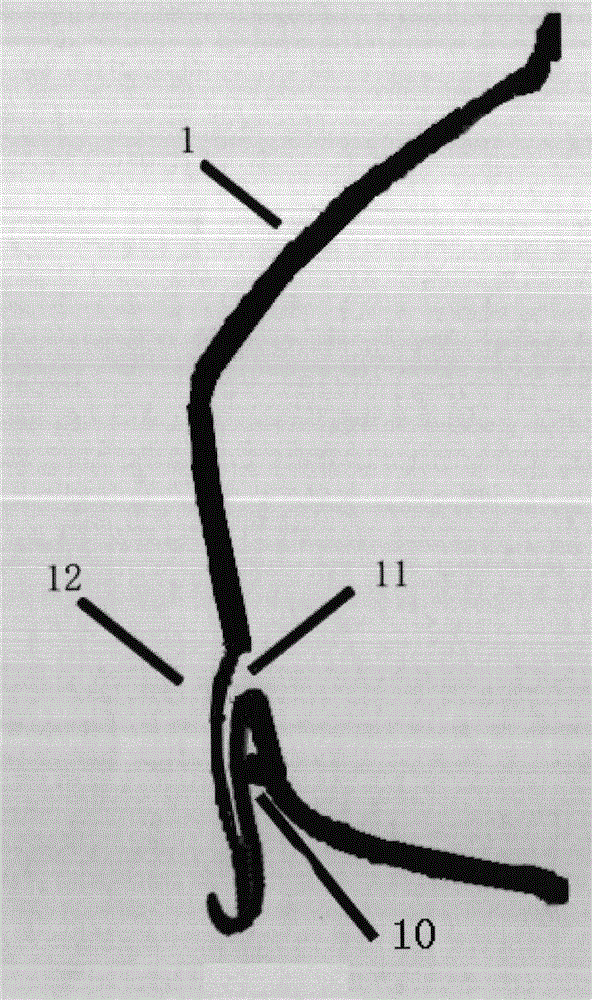

[0028] figure 2 is a...

Embodiment 2

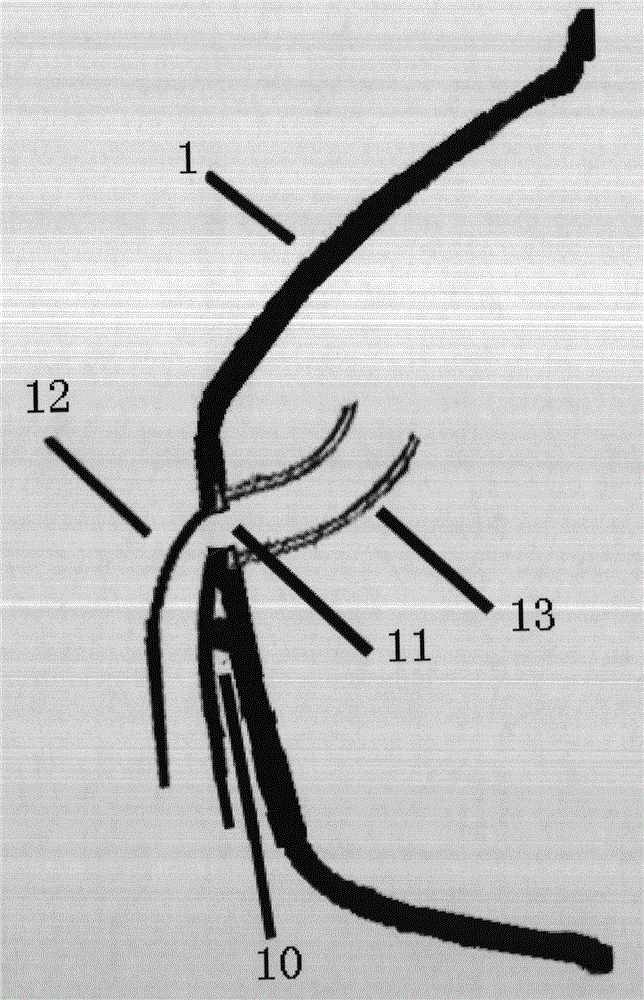

[0034] figure 2 It is a cross-sectional view of Embodiment 2 of the present invention. Embodiment 2 is based on Embodiment 1, adding a nasal plug 13, inhaling through the mouth and exhaling through the nose, realizing that inhalation and exhalation go their own way, completely avoiding In order to form a dead space in the respiratory protection device, keep the inside of the respiratory protection device dry and comfortable.

[0035] As shown in the figure, one end of the nasal prong tube 13 located inside the cover body 1 is airtightly connected to the through hole 11. The connection method is bonding or plugging, preferably plugging, so that the nasal prong tube 13 can be replaced.

[0036] The other end of this nasal plug tube 13 will be inserted in the nostril during use, and this end can be designed into different thicknesses, to adapt to the nostrils of different sizes, further improves the comfortability of wearing.

[0037] In actual use, two one-way channels formed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com