Ammonia spraying regulation automatic control method for denitrification system of thermal power plant

A thermal power plant and control method technology, applied in the direction of non-electric variable control, ratio control, separation method, etc., can solve the problems affecting the control of ammonia injection door and the inability to obtain the content of sulfur and nitrate in flue gas, etc., and achieve the effect of improving the regulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

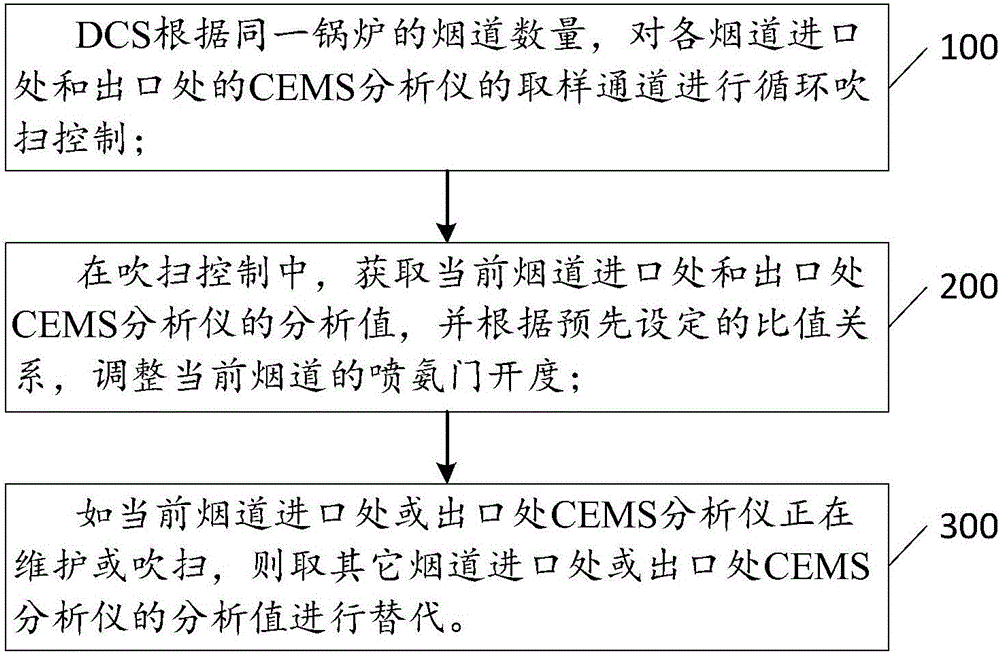

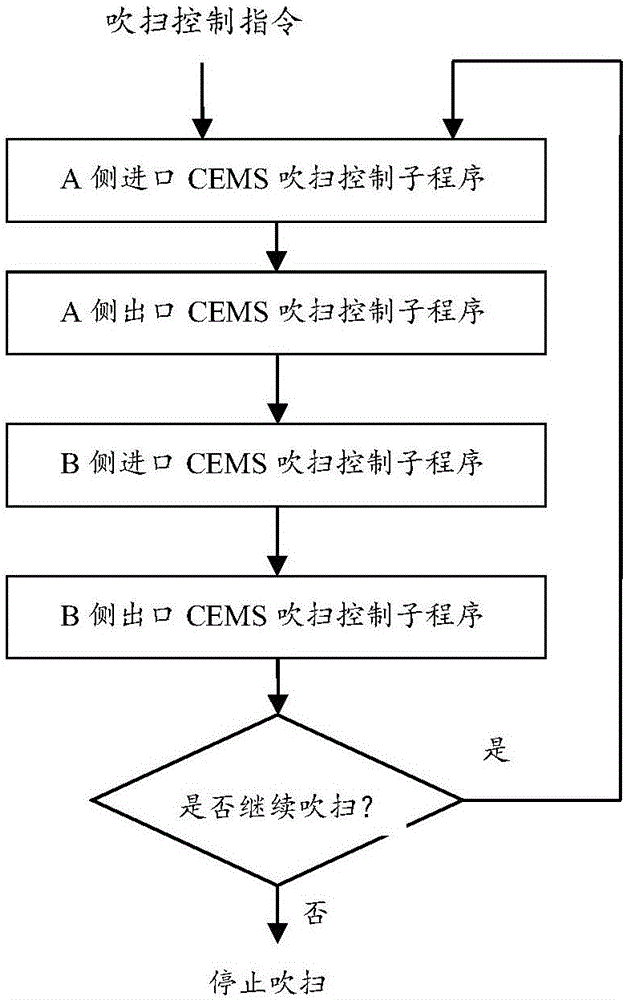

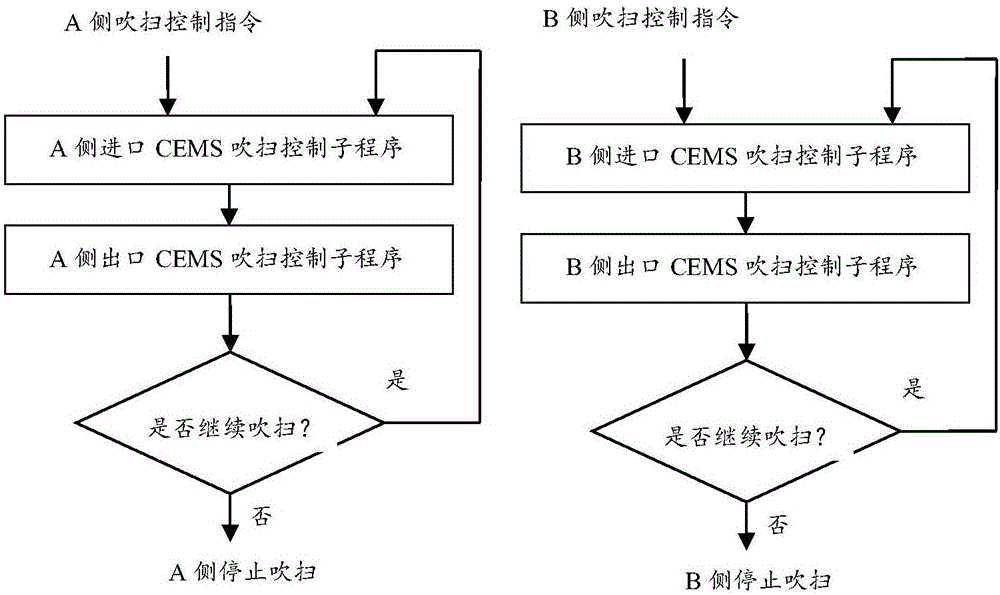

Method used

Image

Examples

Embodiment 1

[0061] Embodiment 1: A control method using the analysis value of another flue CEMS analyzer.

[0062] Such as Figure 5 As shown in , if the current CEMS analyzer at the outlet of side A is working normally, its analysis value will be used directly. If the current CEMS analyzer at the outlet of side A is faulty or is being purged, the analysis value of the CEMS analyzer at the outlet of side B is used, which is determined by the NO at the outlet of side B. x Actual value and NO x The set value is obtained after PID processing, and the obtained value is added to the load of the unit, and finally compared with the NO of the CEMS analyzer at the A side inlet x The analysis values are summed. If the A side inlet CEMS analyzer is being maintained or blown, the analysis value of the B side inlet CEMS analyzer is directly used. According to the results obtained above, manually or automatically adjust the opening of the ammonia injection door of the A-side flue.

[0063] In add...

Embodiment 2

[0064] Embodiment 2: A control method that does not use the analysis value of another flue CEMS analyzer.

[0065] Such as Figure 6 As shown, if the current CEMS analyzer at the A-side outlet is normal, its analysis value will be used directly. If the current CEMS analyzer at the A-side outlet is faulty or is being purged, the load value of the unit is used. The load value includes the current actual load value of the unit and the load value that has been increased or delayed. After adding the two values, and then Scheduled function processing for output. At the same time, if the CEMS analyzer at the inlet of side A is normal, its analysis value will be directly added to the analysis value of the outlet of side A and then output. Otherwise, the load value of the current unit will be considered. unanimous. The added analysis value is used to manually or automatically adjust the opening of the ammonia injection door of the A-side flue.

[0066] In addition, the method for a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com