Box robot welding system

A robotic welding and robotic technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as failure to improve efficiency, waste of money, and failure to correctly find the position of the welding seam.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

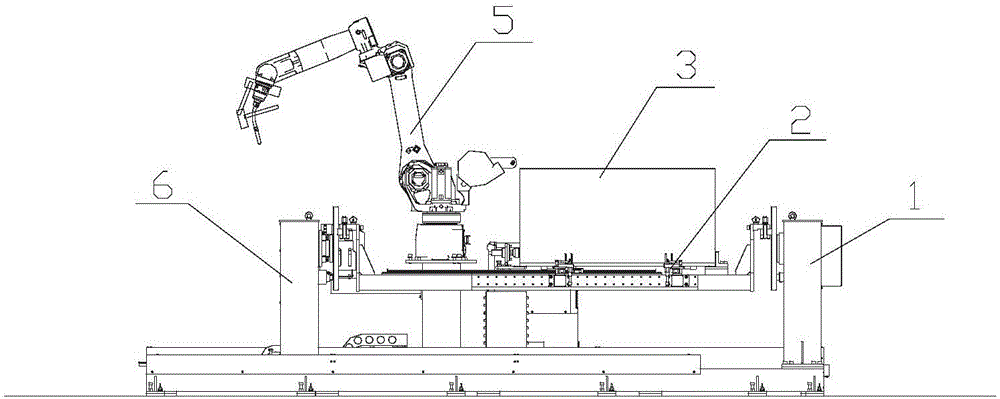

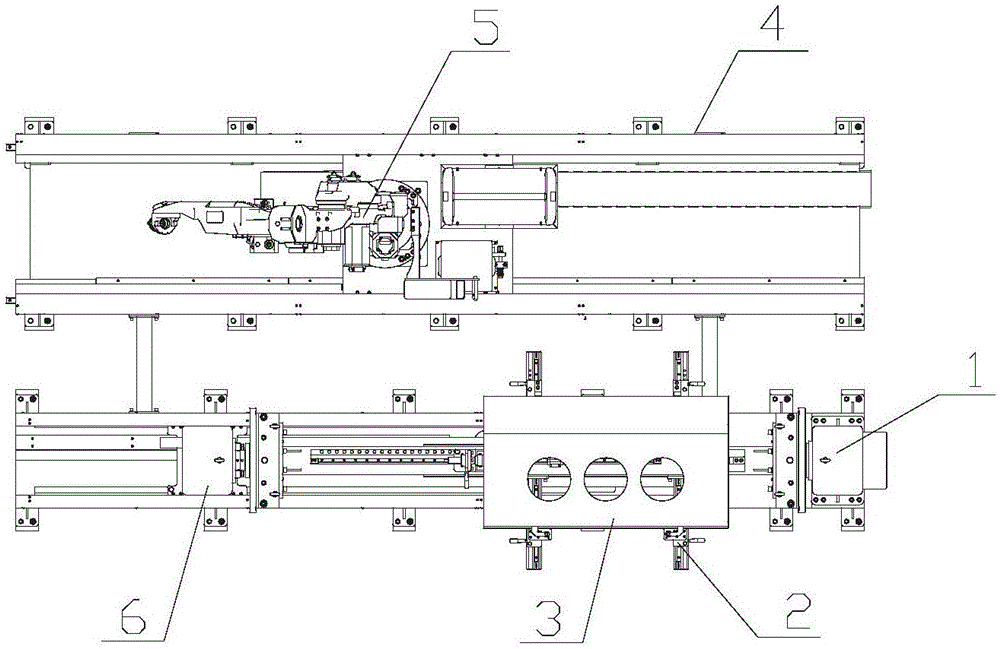

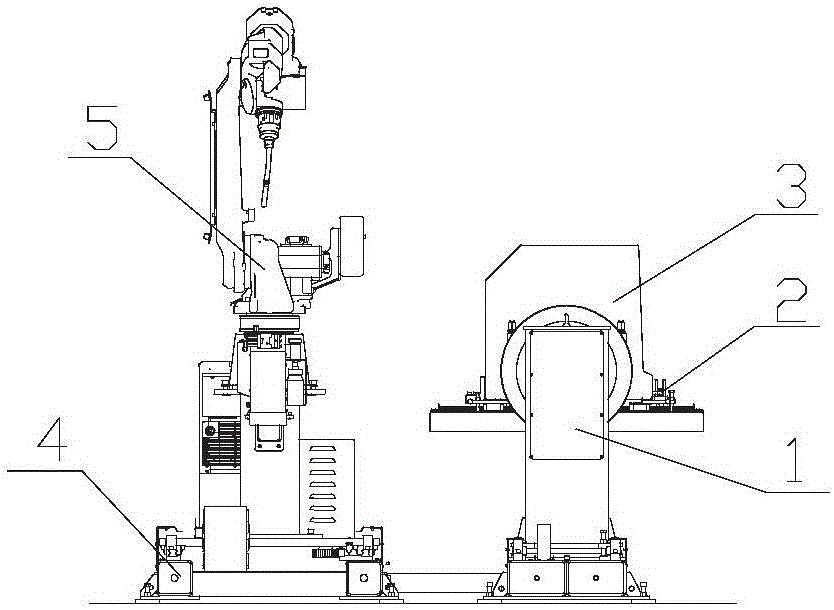

[0039] Such as Figure 1-4 , Figure 9 As shown, a box robot welding system provided by the present invention includes a positioner head frame 1, a fixture 2, a robot sliding table walking mechanism 4, a positioner tailstock 6, a positioner base 9 and a robot welding system 5, wherein the positioner head frame 1 and the positioner tail frame 6 are installed on the positioner base 9, and a slidable positioner tail is provided between the positioner tail frame 6 and the positioner base 9 Frame slide table 10, through positioner tailstock slide table 10 can move along the direction that approaches or moves away from positioner head frame 1, as Figure 9 shown. The two ends of the fixture 2 are respectively connected with the head frame 1 of the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com