round universal wrench

A wrench and circular technology, applied in the field of wrenches, can solve problems such as easy loosening of movable teeth, influence on work progress, and loose bite, etc., and achieve the effects of wide application range, improved efficiency, and prevention of valve slippage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

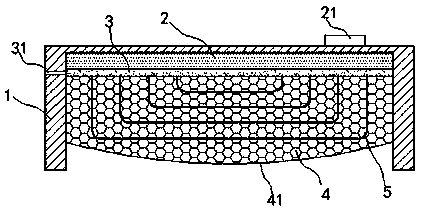

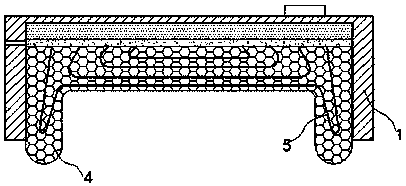

[0018] exist figure 1 , figure 2 In the shown embodiment, the circular universal wrench includes a housing 1, the housing 1 is in the shape of a cylinder with a closed top; anti-slip lines are provided on the outer peripheral wall of the housing 1;

[0019] The storage power source 2 is fixedly arranged on the inner top surface of the housing 1; the on-off switch 21 of the storage power source 2 is arranged on the top of the housing 1;

[0020] An airtight liquid storage chamber 3 is arranged below the storage power source 2; water replenishment holes 31 and drain holes are provided on the liquid storage chamber 3; ;

[0021] An elastic film 41 sealed with the casing 1 is arranged at the bottom of the liquid storage chamber 3, and the lower bottom surface of the elastic film 41, the casing 1 and the liquid storage chamber 3 encloses a torsion chamber 4; The surface of the film 41 is provided with anti-slip particles; the torsion chamber 4 is filled with plastic material; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com