VR (virtual reality) system for remotely controlling mechanical devices

A virtual reality and mechanical device technology, applied in the direction of program control manipulators, manipulators, manufacturing tools, etc., can solve the problems that artificial intelligence technology cannot be popularized in standard operating fields, and the degree of intelligence cannot reach the level of human beings, so as to reduce work The effect of risk and labor intensity, saving time, and ensuring personal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A virtual reality remote control mechanical device system, including an execution terminal and a control terminal:

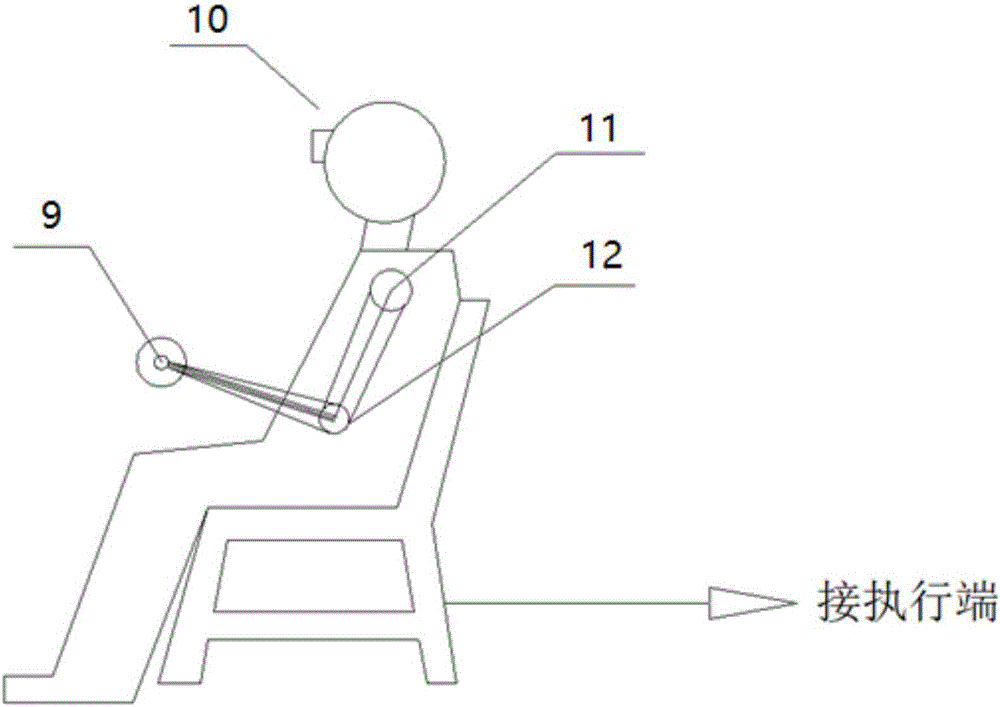

[0027] like image 3 , the control terminal includes a wearable device and a computer connected to it, the wearable device is provided with a control terminal corresponding to the human body structure on the joint and a virtual reality helmet 10;

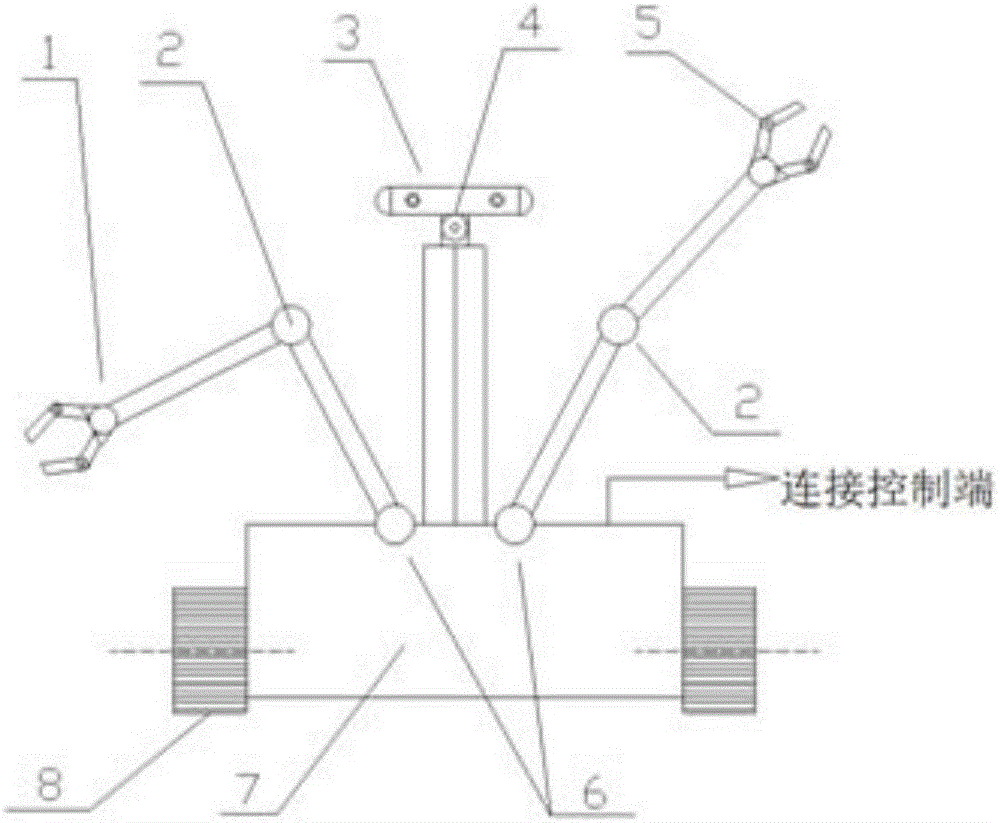

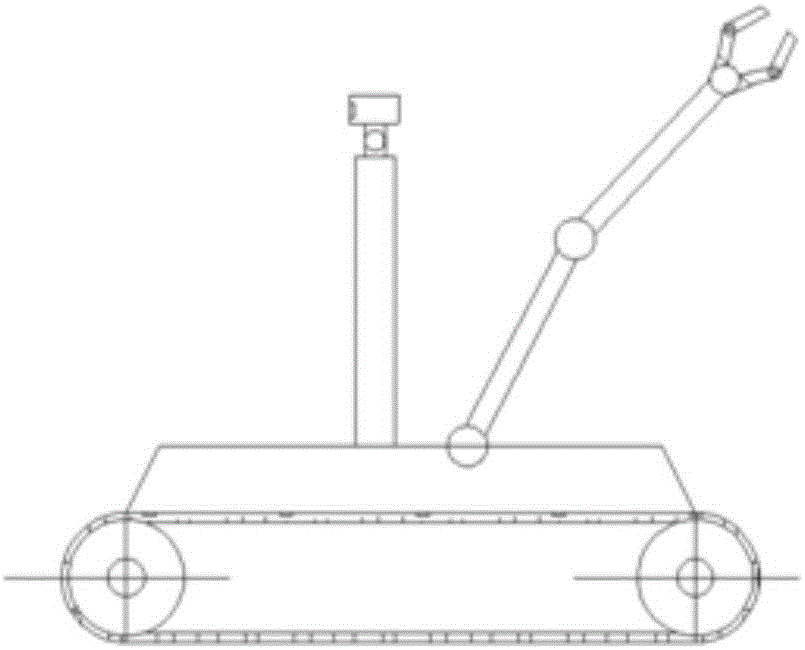

[0028] like Figure 1-2 , the execution end includes a movable industrial robot, the industrial robot is equipped with an execution device corresponding to the wearable device and is equipped with a bionic viewfinder 3 and a two-degree-of-freedom pan-tilt 4 (equivalent to a human neck, which can turn up, down, left, and right) , the wearable device is connected with the industrial robot and sends an action signal to the industrial robot, and the industrial robot returns the video signal to the virtual reality helmet 10 through the bionic viewfinder 3 . The industrial robot at the execution end can operate in ...

Embodiment 2

[0030] In this embodiment, the industrial robot also includes a wrist joint 1, an arm joint 2, a finger joint 5, a shoulder joint 6, and a crawler belt 8 installed on the base and the electrical mechanical assembly 7 according to ergonomics;

[0031] The control terminal includes a wearable device, and the wearable device includes a manipulator control terminal 9, a virtual reality helmet 10, a shoulder joint control terminal 11 and an elbow joint control terminal 12, and each control terminal corresponds to the structure of the human body;

[0032] The control terminal is connected to the execution terminal, the manipulator control terminal 9 of the wearable device performs action signal transmission with the wrist joint 1 and finger joint 5 of the industrial robot, and the elbow joint control terminal 12 of the wearable device performs signal transmission with the arm joint 2 of the industrial robot , the shoulder joint control terminal 11 of the wearable device performs sign...

Embodiment 3

[0036] In this embodiment, the bionic viewfinder 3 includes two CCD cameras with identical parameters to perform real-time image recognition. The remaining technical solutions of this embodiment are consistent with those of Embodiment 2, and the technical solutions adopted in this embodiment are also applicable to other embodiments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com