Improved structure of positioning ring for front top hydraulic oil cylinder of dumper

A technology of hydraulic cylinders and positioning rings, which is applied in the direction of loading and unloading vehicles, motor vehicles, and vehicles used for freight transportation, etc., can solve problems such as abnormal collision noise, achieve the effects of suppressing abnormal noise, facilitating popularization and application, and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

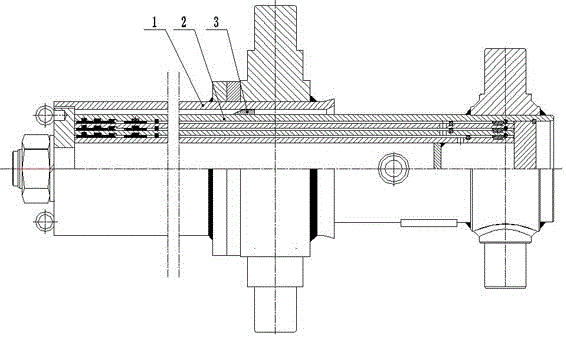

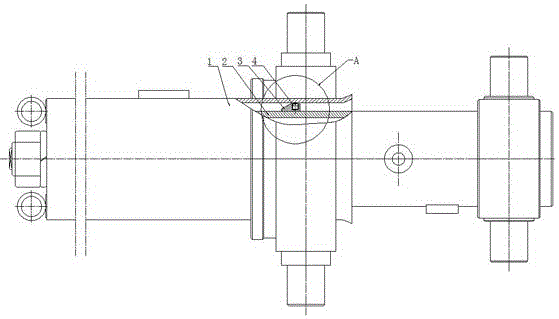

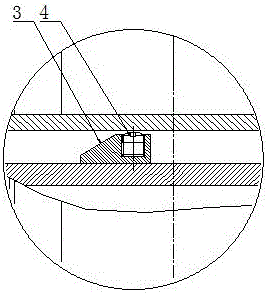

[0015] Such as figure 2 with image 3 As shown, the improved structure of the locating ring for the front jack hydraulic cylinder of the dump truck includes the cylinder cover assembly 1, the outer cylinder assembly 2 and the cylinder locating ring 3, and the lifting end of the outer cylinder assembly 2 is fixed in the cylinder cover assembly 1 , the oil cylinder positioning ring 3 is fixed on the outer peripheral surface of the outer cylinder assembly 2; there are at least four blind holes evenly distributed on the outer ring surface of the oil cylinder positioning ring 3, and each blind hole is provided with a buffer nail 4, four buffer nails The combination of nails has a guiding effect; such as Figure 4 with Figure 5 As shown, the structure of the buffer nail 4 is as follows: including a nail head 401, a coaxial nail rod 402 extending upward from the center of the upper end surface of the nail head 401, the diameter of the nail head 401 is slightly larger than the dia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com