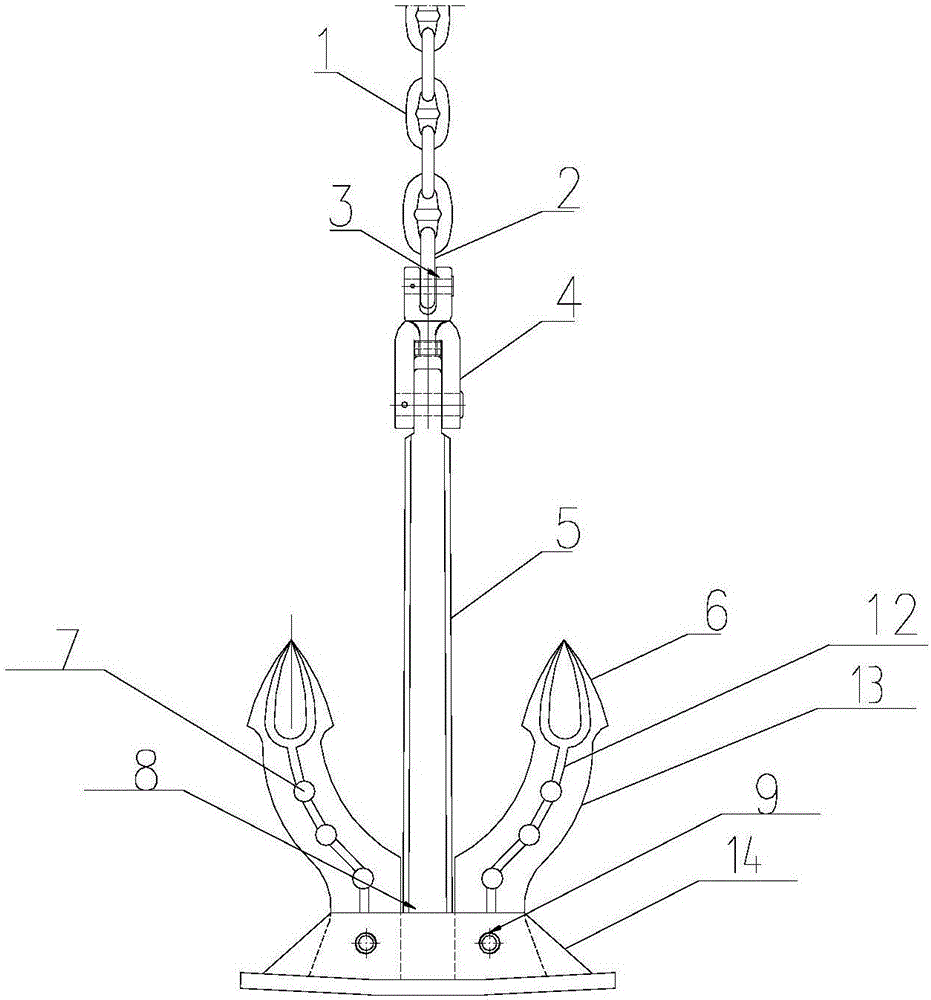

Large-grip-type deep sea anchor

A deep-sea anchor and gripping force technology, applied in anchor points, ship parts, transportation and packaging, etc., can solve the problem of limited research on deep-sea anchors with high gripping force, and achieve increased pullout characteristics, convenient installation and recycling, and improved stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

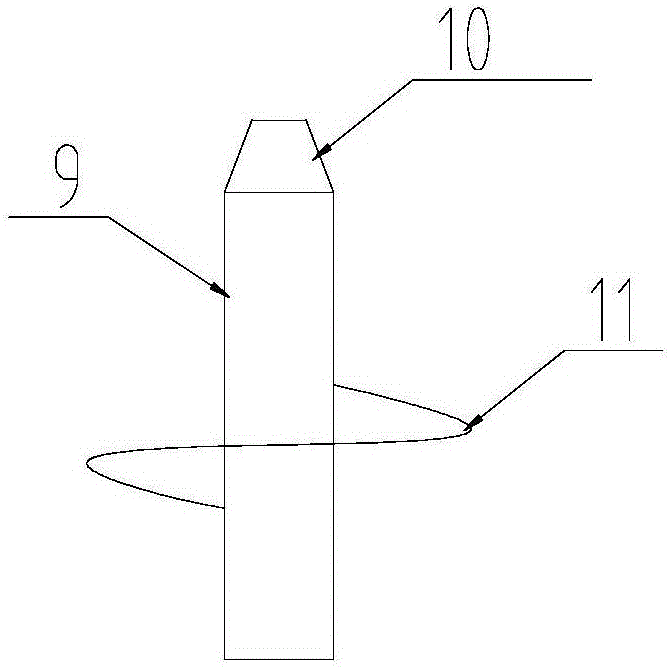

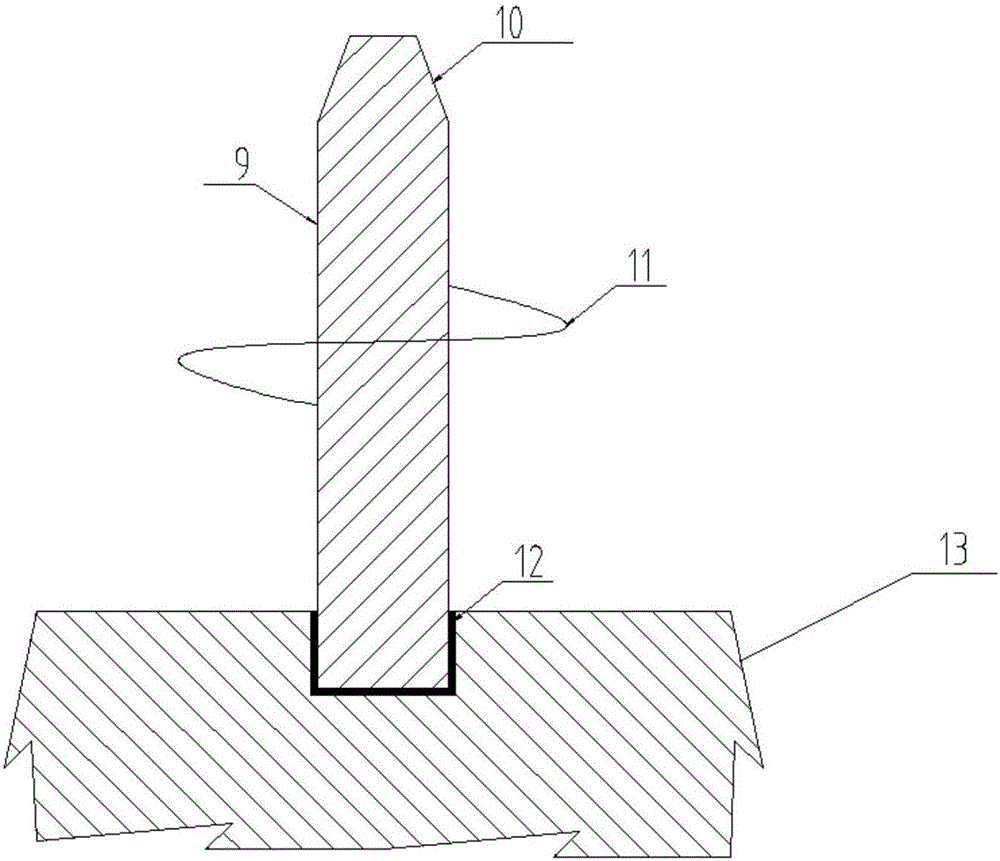

[0025] like Figure 1 to Figure 5 As shown, a deep-sea anchor with a large gripping force of the present invention includes an anchor chain 1, a rotating ring 3 and an anchor handle 5. One end of the anchor chain 1 is an anchor end chain 2, and the anchor end chain 2 is connected to the rotating anchor chain through a bolt 15. The ring 3 is connected, and the rotating ring 3 is connected with the anchor handle 5 through the anchor shackle 4. The end of the rotating ring 3 is cylindrical, and an external thread is provided on the end. A nut 16 is installed on the anchor shackle 4. The rotating ring 3 Screw in the nut 16, a pin hole is provided at the afterbody of the rotating end, a latch 19 is installed in the pin hole, and a lock pin is installed at both ends of the latch 19, and the lock pin acts to limit the movement of the latch 19, and the anchor handle 5 is connected to the anchor head 14 through the small shaft 8, the anchor handle 5 rotates around the small shaft 8, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com