Environment-friendly ground horizontal type waste compacting transfer station

A garbage compression and horizontal technology, applied in garbage bins, garbage delivery, garbage collection, etc., can solve the problems of large environmental pollution, difficult to clean, sewage energy consumption, etc., to reduce manufacturing costs, save material space, and low maintenance costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

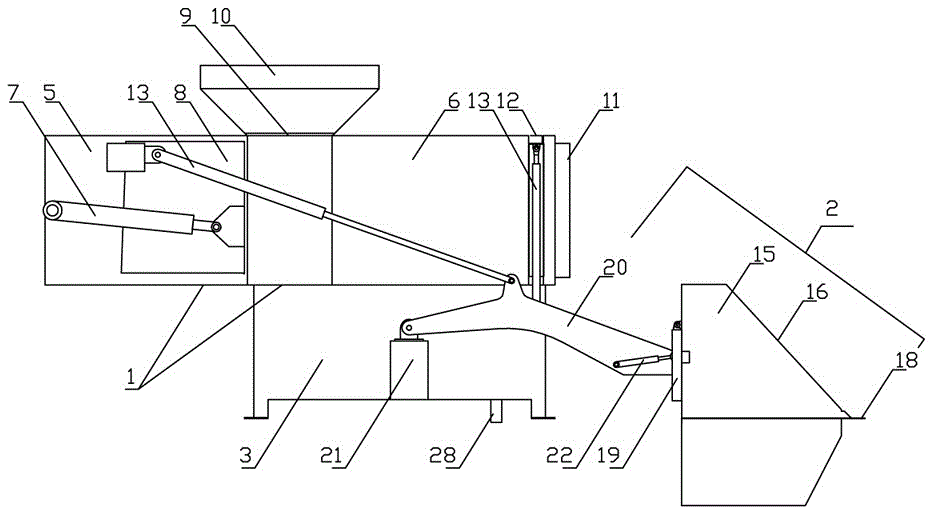

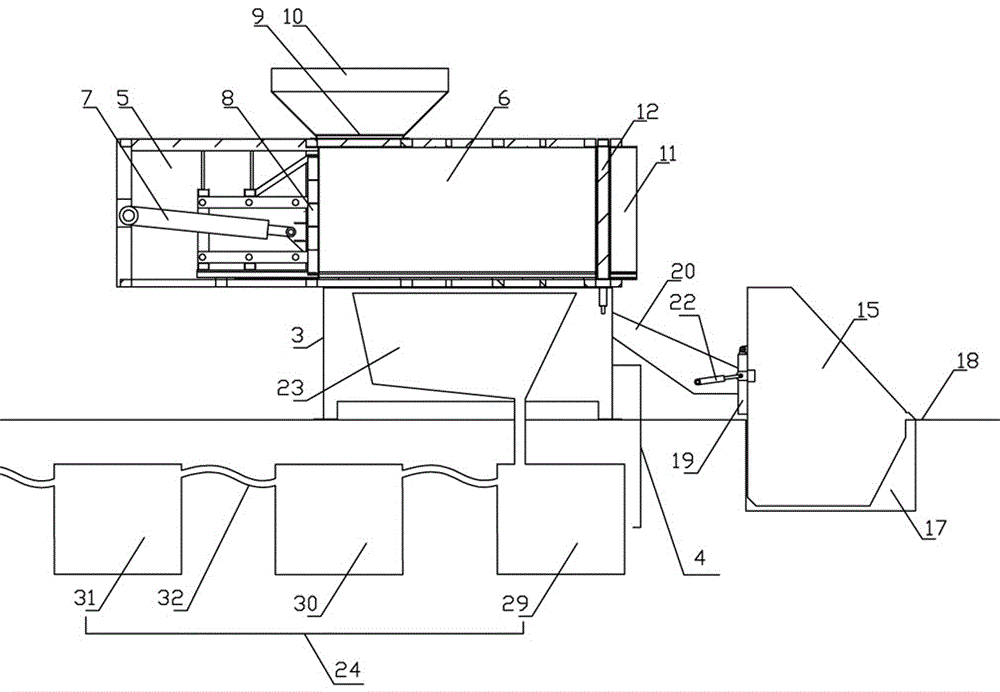

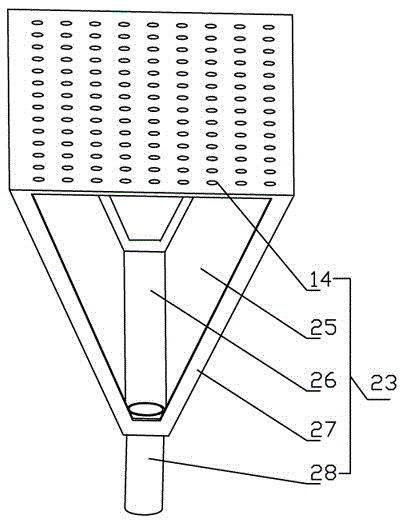

[0023] In this embodiment, an environment-friendly ground-level garbage compression transfer station has a horizontal compression box 1, a feeding device 2 is hingedly installed at one end of the compression box 1, and a support box is welded at the bottom of the compression box 1 body 3, a sewage discharge device 4 is installed in the support box body 3, an oil cylinder chamber 5 and a compression chamber 6 are arranged in sequence in the compression box body 1, and a hydraulic push cylinder 7 is installed in the oil cylinder chamber 5, and the end of the hydraulic push cylinder 7 is connected with The compression push plate 8 is used to compress the garbage into pieces. There is a feed port 9 above the end of the compression cavity 6 close to the compression push plate 8. An anti-spill funnel 10 is installed on the feed port 9. The other end of the compression cavity 6 It is the discharge port 11, and there is a gate 12 between the compression chamber 6 and the discharge port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com