Rail-mounted material lifting device

A track-type, track-based technology, applied in the direction of transportation and packaging, conveyors, mechanical conveyors, etc., can solve the problems that ordinary transportation tools cannot be completed, ordinary elevators cannot work, and the slope of the diversion section is large, so as to achieve a variety of material transfer methods , to ensure smooth progress and high transport efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with example, accompanying drawing, the present invention is described in further detail.

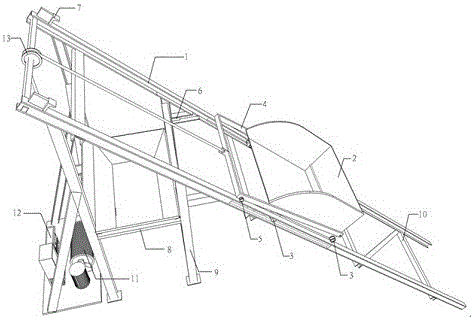

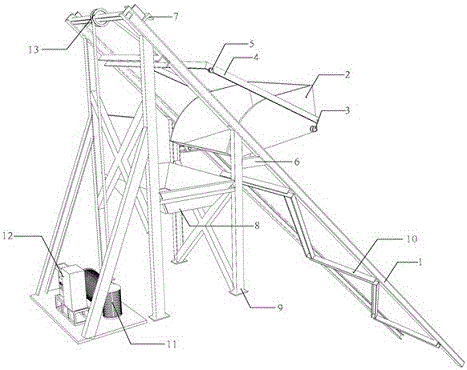

[0026] Such as figure 1 As shown, a rail-type material lifting device includes two inclined rails, one end of the rails is provided with a support frame, and the support frame supports the entire rail obliquely; There is a hoist, and a fixed pulley is arranged on the upper end of the track, and the steel cable on the hoist is connected to the vehicle body through the fixed pulley, so that the vehicle body can slide up and down along the track under the action of the hoist; There is a funnel for collecting materials, and a horizontal slide rail is set between the upper support of the funnel and the track, so that the car bucket can slide from the inclined track to the horizontal slide rail, and the car bucket can go above the funnel, so as to carry out the material pouring.

[0027] In order to ensure a better implementation of the whole device, the wheel se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com