Elevator applied to local high-temperature environment

A local high temperature and environmental technology, applied in the field of elevators, to avoid excessive local temperature and improve the cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

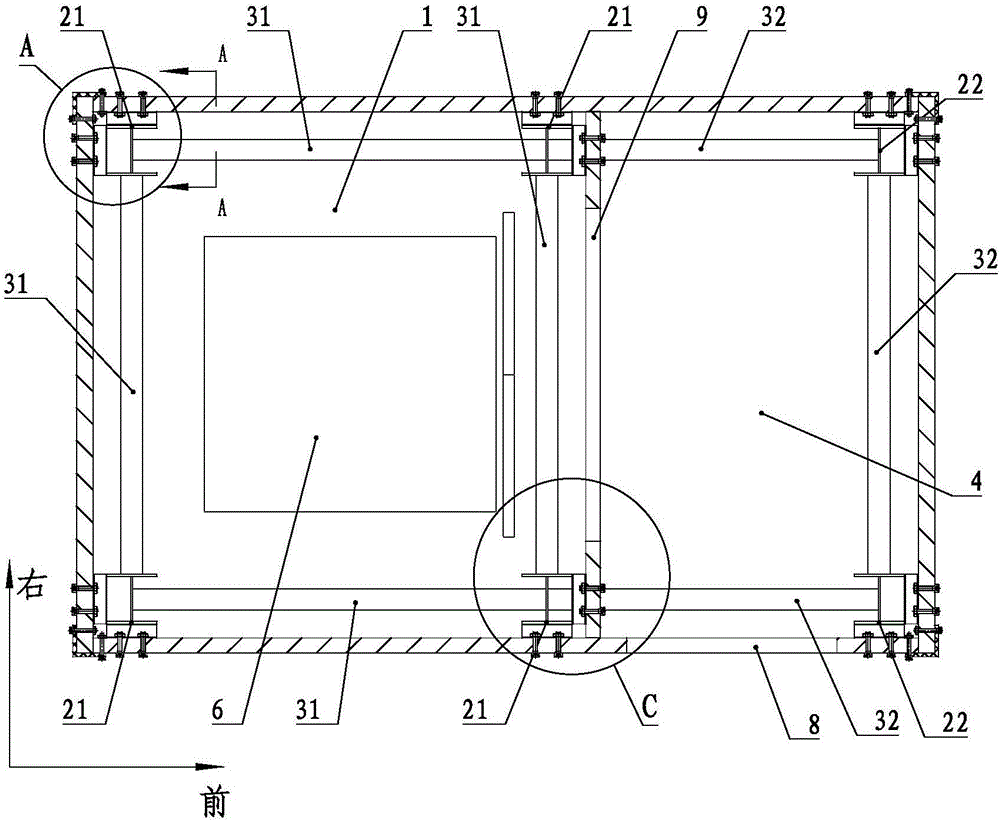

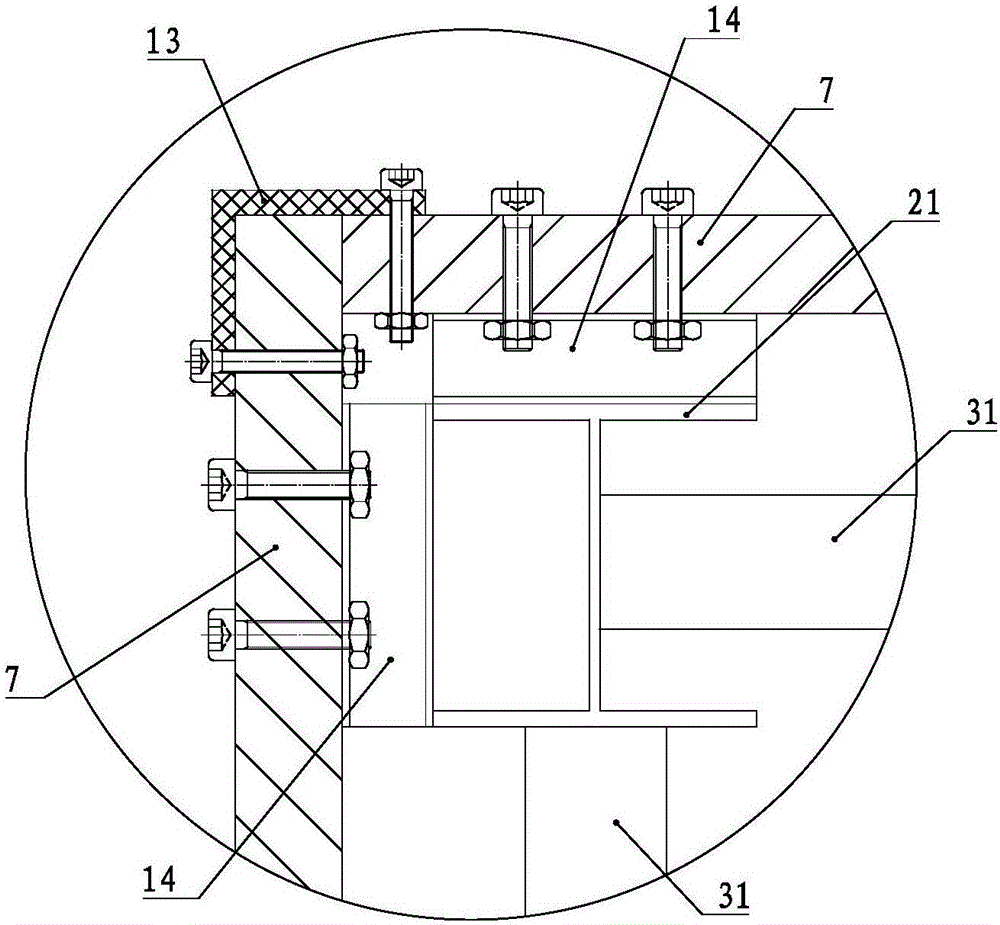

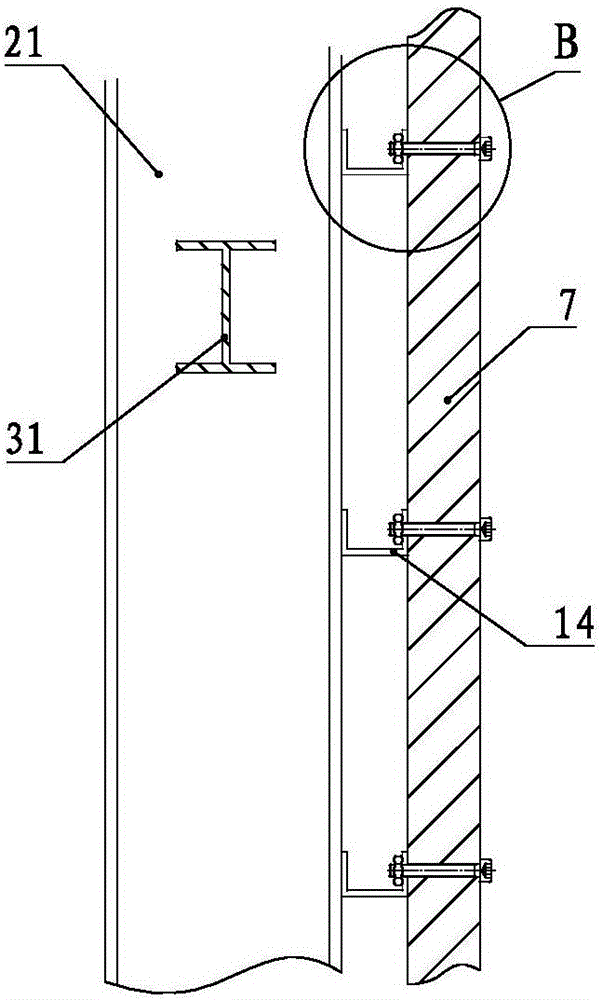

[0037] like figure 1 and Figure 6 As shown, a kind of elevator that is applied in local high temperature environment comprises elevator shaft frame, safety door, elevator door 15 (for convenience of description, described elevator door 15 refers to the door that communicates with car 6 on the elevator shaft frame , the door on the car 6 is defined as the car 6 door) and the machine room, the elevator shaft frame includes four vertically arranged first steel columns 21, and between adjacent first steel columns 21 along A number of first steel beams 31 are evenly distributed in the vertical direction, and the first steel columns 21 and the first steel beams 31 together form a square structure elevator shaft frame. The elevator shaft 1 formed by the elevator shaft frame is provided with a car 6, and a transmission mechanism is arranged between the car 6 and the elevator shaft 1, and the transmission mechanism adopts a transmission mechanism in the prior art That is, it will no...

Embodiment 2

[0049] In order to make the cooling air evenly distributed in the elevator shaft 1, such as Figure 8 As shown, the air outlet 112 of the second cooling duct 11 is provided with a U-shaped air outlet pipe 111, and the car 6 is located inside the opening of the U-shaped air outlet pipe 111. , the upper surface of the air outlet pipe 111 is provided with several air outlets 112 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com